Device for 3D printing of baking-free bricks through river and lake bottom mud and manufacturing method

A 3D printing and production method technology, applied in the field of 3D printing, can solve the problems of single use of unburned bricks for river and lake bottom mud, inability to flexibly apply to various projects, and inconvenient collection and transportation of river and lake bottom mud, so as to achieve convenient construction and various forms , to reduce the effect of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032] Example 1:

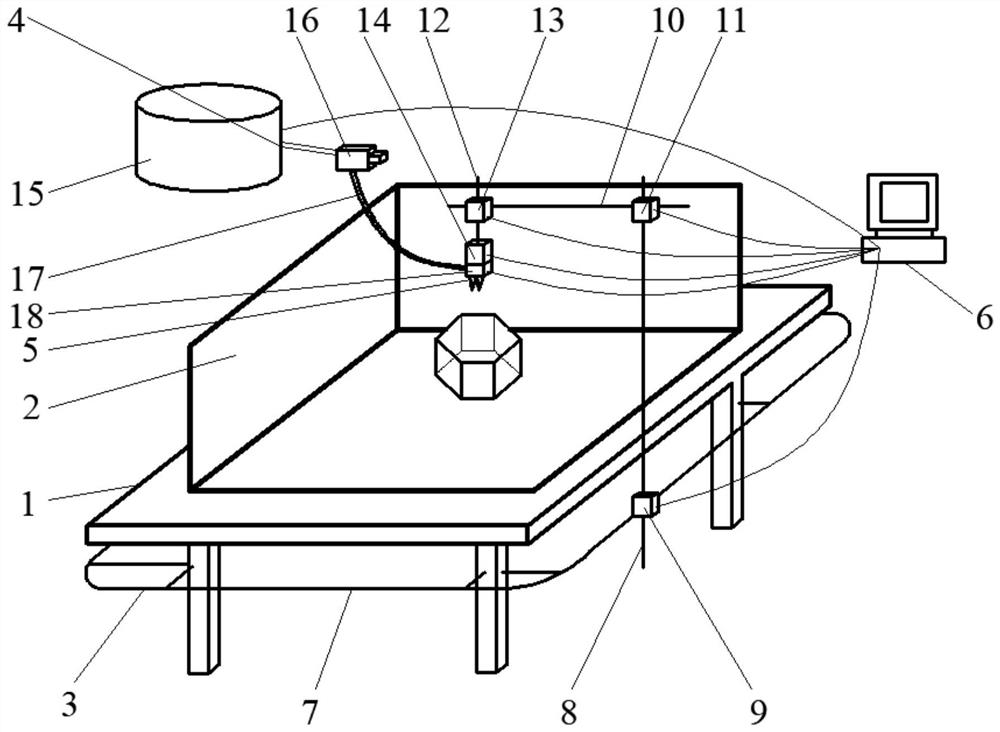

[0033] refer to figure 1 The present invention provides a technical solution, a device that prints no burn bricks using the river lake in the bottom mud 3D, including the test bench 1, the model groove 2, the moving portion 3, the feed portion 4, the print nozzle 5, and the controller 6; The model slot 2 is disposed on the experimental platform 1, the feed unit 3 is connected to the print pad 5, and the controller 6 is used to control the moving unit 3, the feed portion 4, and the print nozzle 5;

[0034]The moving unit 3 includes a ring slide rail 7, a first slide rail 8, a first mobile device 9, a second sliding rail 10, a second mobile device 11, a third slide rail 12, a third mobile device 13, and a fourth mobile device 14. The annular slide 7 is a closed annular orbit consisting along the test bench 1, and the annular slide rail 7 is fixed to four support columns at the bottom of the test bearing 1; the first slide rail 8 is disposed in the vertical direct...

Example Embodiment

[0039] Example 2:

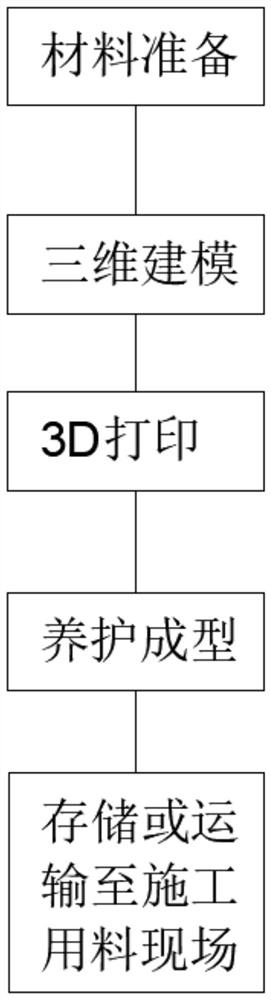

[0040] refer to Figure 1-6 The present invention provides a technical solution, a method of printing the burn bricks, using a river lake sessate, using a device for printing the burn bricks with the river lake in Example 1, including the following steps:

[0041] First, the material is prepared: the bottom of the river lagoon is pulpatically, and then the submerged river lake sessate is stirred with the curing agent, the appliance is stirred and loaded into the stirring cell, add water, aggregate to obtain a 3D printing substrate;

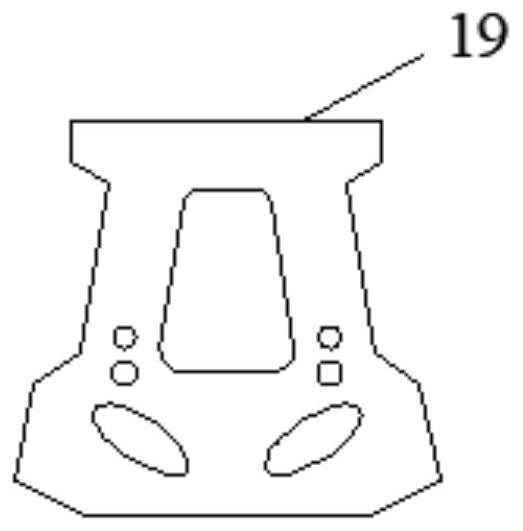

[0042] Second, three-dimensional modeling: use 3D modeling software to establish the size of the three-dimensional stereoscopic model of the flask brick; the three-dimensional stereoscopic model of the flask brick includes a six-roll slope tile 20, a honeycomb slope tile 21, a self-eated wall block 19 and Interlocking sliding tile 22, the self-eated wall block 19 is a trapezoidal structure, the six-prism slope tile 20 is a six-ride ...

Example Embodiment

[0048] Example 3:

[0049] refer to Figure 1-6 On the basis of Example 2, the 3D printing substrate was made of the following mass percentage of raw materials: 60% of the river lake, 18% curing agent, 15% natural stone, 5%, high-efficiency water reducer 2%, each The sum of the components of mass is 100%. The bottom mud is not required to be dehydrated. The water content is 60% by weight, and the resulting 28D 3D print free burn brick is intensified. Its compressive strength is 15MPa, and the "Hazardous Waste Identification Standard Leaching Toxicity Different" (GB5085 .3-2007).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap