Production method of high-purity cadmium sulfate 8/3-hydrate

A production method, the technology of cadmium sulfate, is applied in the field of production of high-purity cadmium sulfate 8/3 hydrate, which can solve the problems of hidden safety and environmental protection, large amount of hydrogen generation, and low production efficiency, so as to achieve low production cost and high production efficiency. The effect of high rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

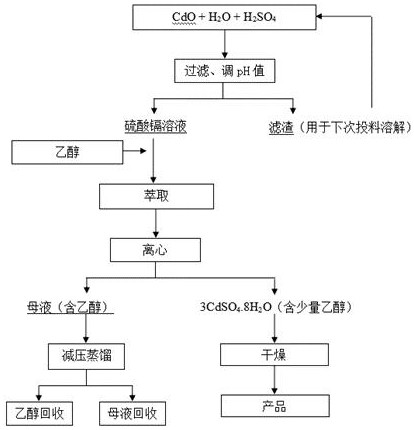

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of eight-thirds cadmium sulfate hydrate comprises the steps:

[0030] (1) Take 2.6L of water, put it into a beaker, slowly add 540ml of analytically pure sulfuric acid (98%), stir, and then add cadmium oxide in batches, a total of 1.275kg, the molar ratio of cadmium oxide to sulfuric acid is 1.02:1.00, React for 3 hours, control the pH value of the reaction end point to 2.5-3 by adding sulfuric acid, filter with suction, and then evaporate at 90°C until the specific gravity is 1.62g / mL;

[0031] (2) After cooling to room temperature, mix the two according to the volume ratio of cadmium sulfate solution: ethanol at 1:1, mix at room temperature and under ventilation, stir with an explosion-proof motor, stir for 0.5 hours and then centrifuge at a medium speed for 1 hour to obtain the mother liquor The medium alcohol is recycled under reduced pressure, and the obtained crystals are aired in a ventilated place for 8 hours at a temperature of 28°C and a...

Embodiment 2

[0034] The preparation method of eight-thirds cadmium sulfate hydrate comprises the steps:

[0035] (1) Take 2.7L of water, put it into a beaker, slowly add 540ml of analytically pure sulfuric acid (98%), stir, and then add cadmium oxide in batches, a total of 1.315kg, the molar ratio of cadmium oxide to sulfuric acid is 1.05:1.00, React for 10 hours, the pH value at the end of the reaction is 3.5-4, filter with suction, and then evaporate at 110°C until the specific gravity is 1.65g / mL;

[0036] (2) After cooling to normal temperature, mix the two according to the volume ratio of cadmium sulfate solution and ethanol as 1:1.5, mix them at room temperature and under ventilation, stir with an explosion-proof motor, stir for 0.1 hour and then centrifuge at medium speed for 0.5 hour, and the mother liquor Medium alcohol is recycled under reduced pressure distillation, and the crystal is dried in a ventilated place for 12 to 16 hours at a temperature of 25°C and a relative humidity...

Embodiment 3

[0039] The preparation method of eight-thirds cadmium sulfate hydrate comprises the steps:

[0040] (1) Take 2.65L of water, put it into a beaker, slowly add 540ml of analytically pure sulfuric acid (98%), stir, then add cadmium oxide in batches, a total of 1.369kg, the molar ratio of cadmium oxide to sulfuric acid is 1.09:1.00, React for 7 hours, the pH at the end of the reaction is 4.5-5, filter with suction, and then evaporate at 100°C until the specific gravity is 1.7g / mL;

[0041] (2) After cooling to normal temperature, mix the two according to the volume ratio of cadmium sulfate solution and ethanol as 1:0.8, mix them at room temperature and under ventilation, stir with an explosion-proof motor, stir for 1 hour and then centrifuge at medium speed for 2 hours, and the mother liquor The medium alcohol is recycled under reduced pressure, and the obtained crystals are aired in a ventilated place for 36 hours at a temperature of 30°C and a relative humidity of 60% to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com