Benzocyclobutene-containing functionalized organosilicon compound and preparation method thereof

A benzocyclobutene functional, organosilicon compound technology, applied in the field of chemical materials to achieve the effects of excellent thermal stability, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

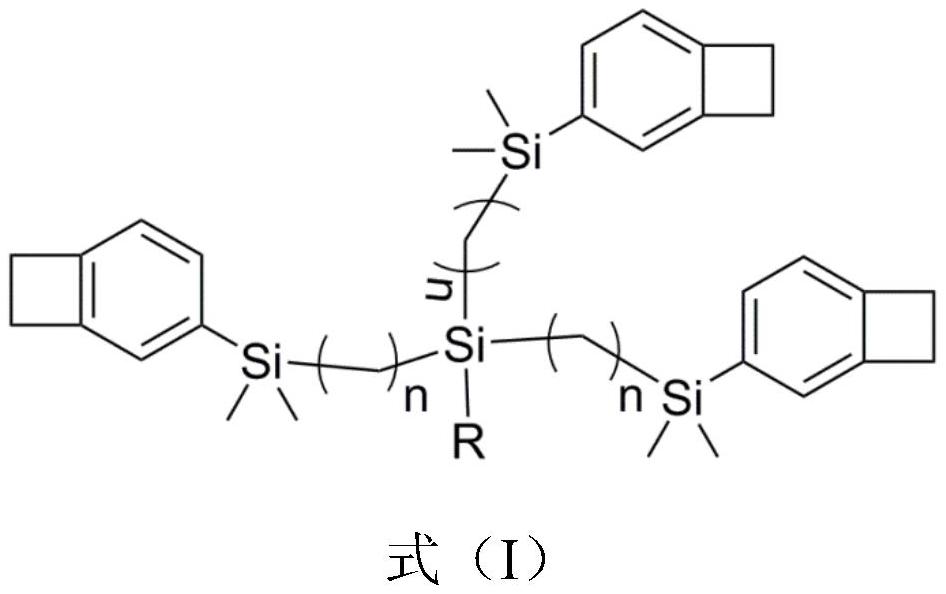

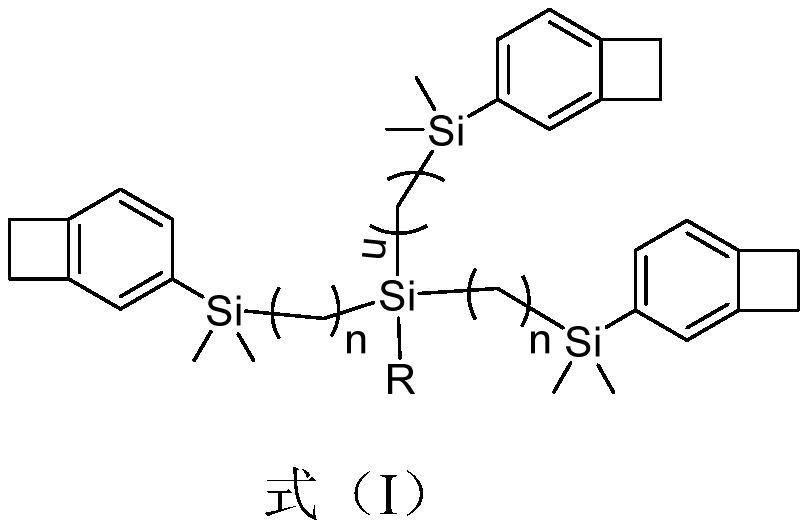

[0033] Methyl, tris (dimethyl, benzocyclobutenyl silyl ethyl) silane (MTBCBSES), its chemical formula:

[0034]

[0035] The preparation method of MTBCBSES: In a dry anaerobic bottle equipped with a magnetic stirrer, add 5g of methyltrivinylsilane, 25g of 4-DMHSBCB, and a molar concentration of 0.025M (catalyst) H 2 PtCl 6 200 μL of tetrahydrofuran solution and 60 mL of toluene, the mixture was reacted at 70°C under nitrogen atmosphere for 40 hours, and the reaction raw material methyltrivinylsilane was monitored by thin layer chromatography to see if the reaction was complete. After the reaction is over, cool the reacted material to room temperature, add ethanol with 10 times the mass of the reacted material, precipitate, and filter; the solid (i.e., precipitate) obtained after filtration is placed in a vacuum drying oven at a pressure of -0.09 to - Dry at 0.095 MPa and 90° C. for 12 hours to obtain a paste-like product, that is, methyl, tris(dimethyl, benzocyclobutenylsi...

Embodiment 2

[0038] Phenyl, tris(dimethyl,benzocyclobutenylsilylethyl)silane (PTBCBSES), its chemical structure:

[0039]

[0040] The preparation method of PTBCBSES: In a dry anaerobic bottle equipped with a magnetic stirrer, add 8 g of phenyltrivinylsilane, 30 g of 4-DMHSBCB, and a molar concentration of 0.025M (catalyst) H 2 PtCl 6200 μL of tetrahydrofuran solution and 60 mL of toluene, the mixture was reacted at 90° C. for 60 hours under a nitrogen atmosphere, and the reaction raw material phenyltrivinylsilane was monitored by thin-layer chromatography to see if the reaction was complete. After the reaction is over, cool the reacted material to room temperature, add ethanol with 10 times the mass of the reacted material, precipitate, and filter; the solid (i.e., precipitate) obtained after filtration is placed in a vacuum drying oven at a pressure of -0.09 to - Dry at 0.095 MPa and 90° C. for 12 hours to obtain a paste product, that is, phenyl, tris(dimethyl, benzocyclobutenylsilyl...

Embodiment 3

[0043] Methyl, tris (dimethyl, benzocyclobutenylsilylpropyl) silane (MTBCBSPS), its chemical formula:

[0044]

[0045] The preparation method of MTBCBSPS: In a dry anaerobic bottle equipped with a magnetic stirrer, add 5-8g of methyltriallylsilane, 20-30g of 4-DMHSBCB, and a molar concentration of 0.025M (catalyst) H 2 PtCl 6 200 μL of tetrahydrofuran solution and 60 mL of toluene, the mixture was reacted at 80° C. for 24 hours under a nitrogen atmosphere, and the reaction raw material methyltriallylsilane was monitored by thin-layer chromatography to see if the reaction was complete. After the reaction is over, cool the reacted material to room temperature, add ethanol with 10 times the mass of the reacted material, precipitate, and filter; the solid (i.e., precipitate) obtained after filtration is placed in a vacuum drying oven at a pressure of -0.09 to - Dry at 0.095 MPa and 90° C. for 12 hours to obtain a paste-like product, that is, methyl, tris(dimethyl, benzocyclob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com