A control method for a hydrogen-ammonia dual-fuel zero-carbon rotor machine without tempering

A zero-carbon rotor, control method technology, applied in fuel injection control, engine control, electrical control, etc., can solve problems such as limiting wide application, hydrogen rotor machine tempering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

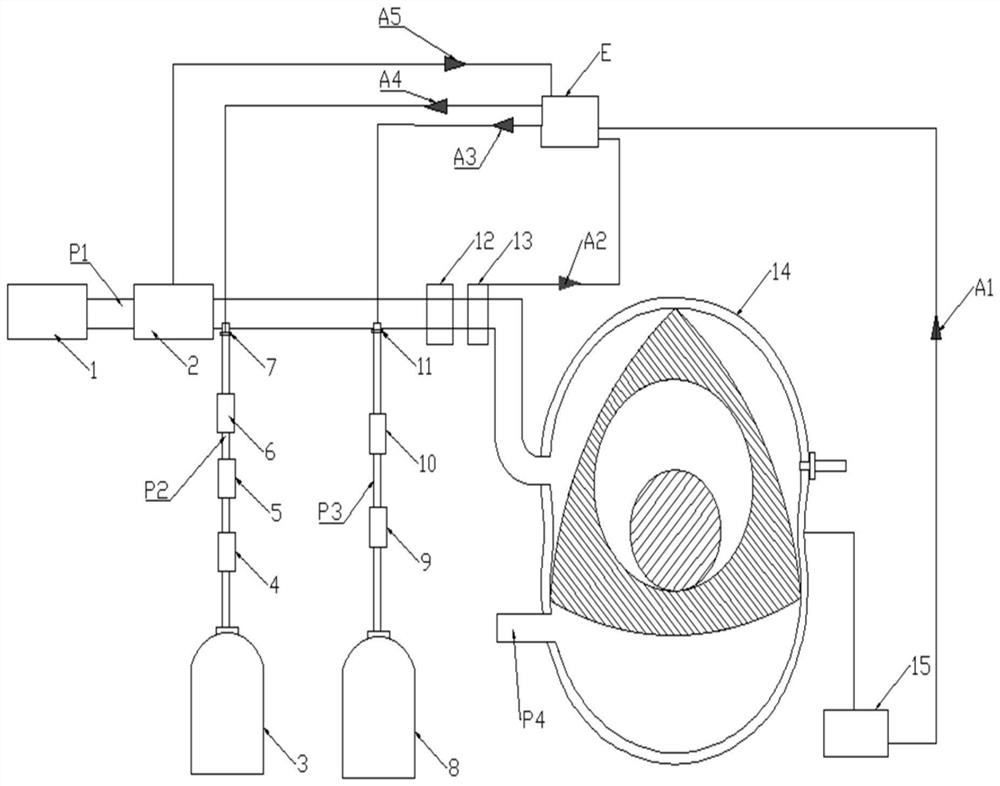

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0017] It includes: an intake pipeline (P1), on which are connected in series: an air filter (1), an air volume flow sensor (2), a throttle valve (12) and an intake pressure sensor (13); a hydrogen supply pipeline ( P2), on which are connected in series: a hydrogen tank (3), a hydrogen pressure reducing valve (4), a hydrogen volume flowmeter (5), a flame arrester (6) and a hydrogen nozzle (7), and the hydrogen passes through the hydrogen nozzle (7) Enter the intake pipeline (P1); the ammonia supply pipeline (P3), which is connected in series with: ammonia tank (8), ammonia pressure reducing valve (9), ammonia volume flowmeter (10) and ammonia gas Nozzle (11), ammonia gas enters the intake pipe (P1) through the ammonia gas nozzle (11); ammonia gas, hydrogen gas and fresh air are mixed before the throttle valve (12), and then enter the rotor mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com