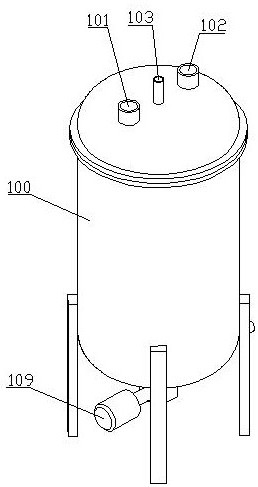

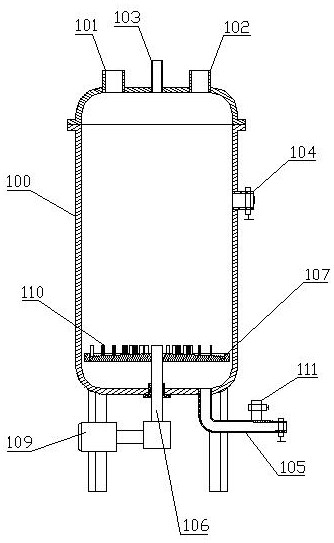

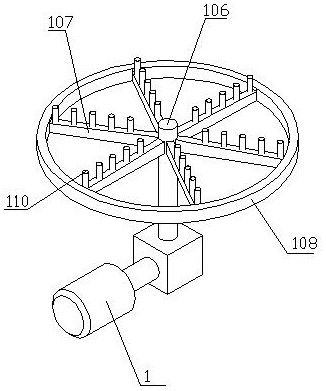

Special tank for washing drilling oil sludge

A technology for washing tanks and oil sludge, which is applied in water/sludge/sewage treatment, sludge treatment, mining wastewater treatment, etc. It can solve the problems of poor mixing and separation effect and affect the production efficiency of the factory, and achieve fast separation speed and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] In order to make the objects, technical solutions, and advantages of the present invention more clearly, the technical solutions in the embodiments of the present invention will be described in contemplation in the embodiment of the present invention. It is an embodiment of the invention, not all of the embodiments. Components of the embodiments of the present invention described and illustrated in the drawings herein can be arranged and design in various configurations. Thus, the following detailed description of the embodiments of the invention in the drawings is not intended to limit the scope of the invention claims, but only the selected embodiments of the present invention are shown. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise. It should be noted that similar reference numerals and letters represent the similar ite...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap