Acrylic plate cutting and powder treatment integrated device

An acrylic sheet and powder technology, applied in grain processing, metal processing, etc., can solve the problems of inability to recycle waste, inability to conveniently clamp sheets, and inability to cut sheets in batches, etc., to achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

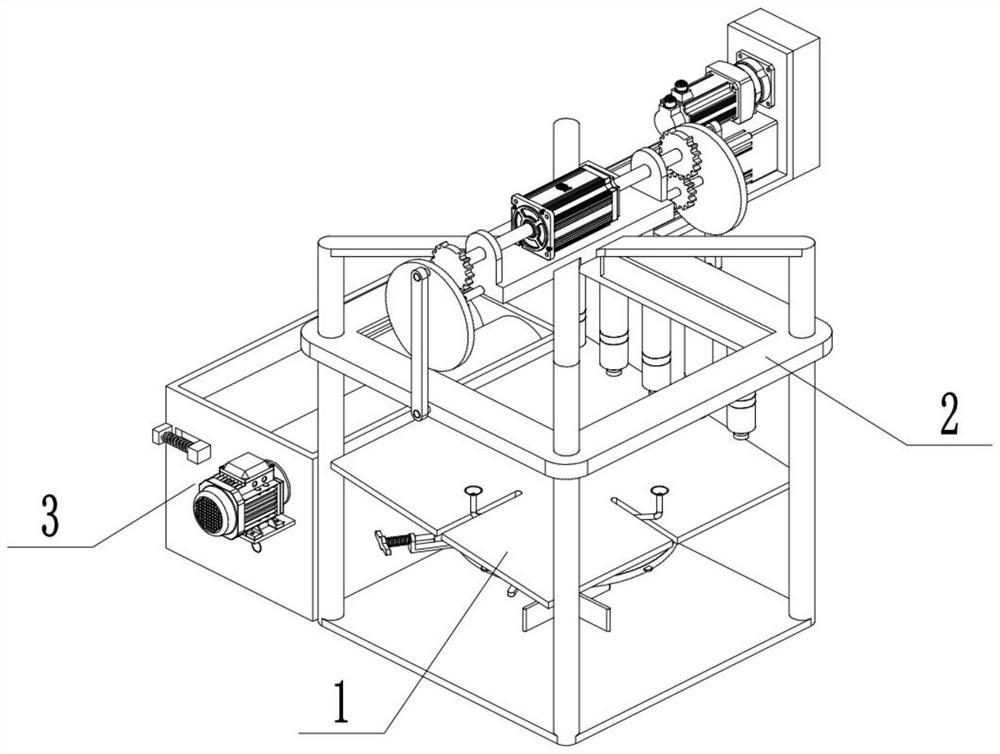

[0026] Combine below Figure 1-12 Describe this embodiment, an acrylic plate cutting powder processing integrated equipment, including a support adjustment assembly 1, a cutting assembly 2 and a powder assembly 3, the cutting assembly 2, powder assembly 3 are all combined with a support adjustment Body 1 is connected.

specific Embodiment approach 2

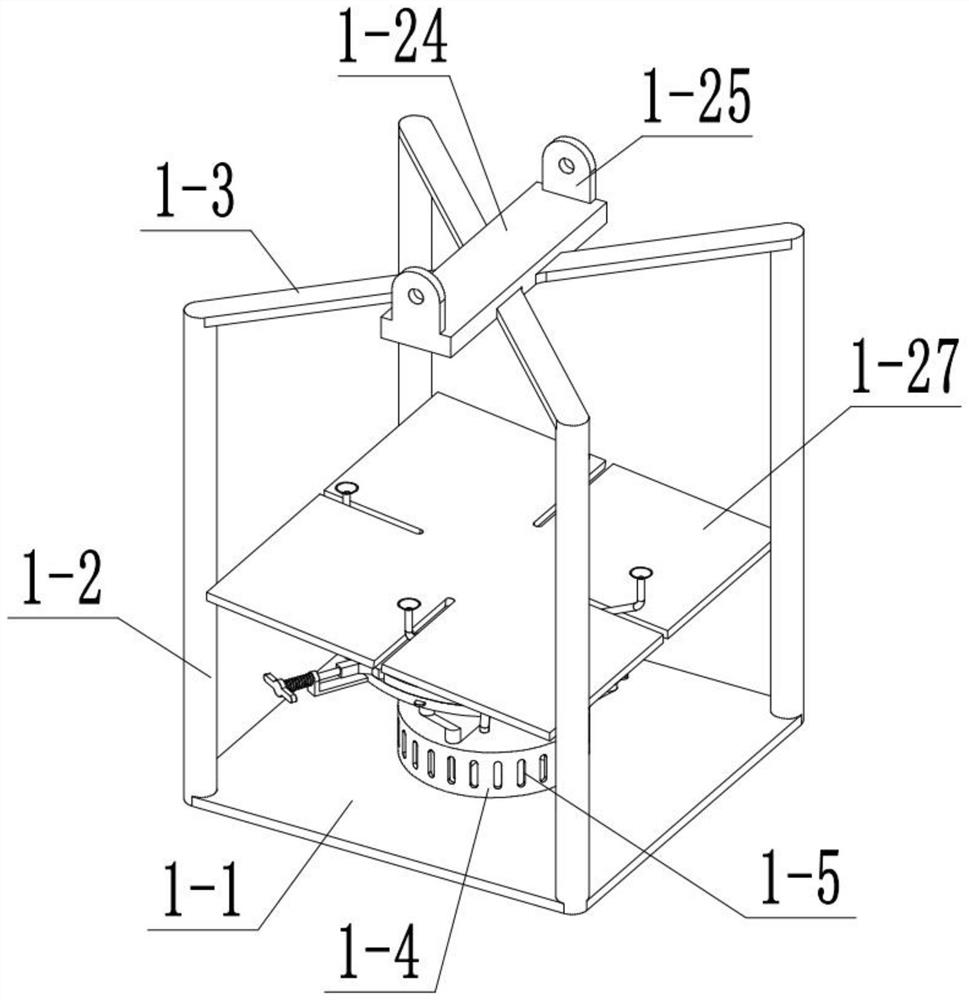

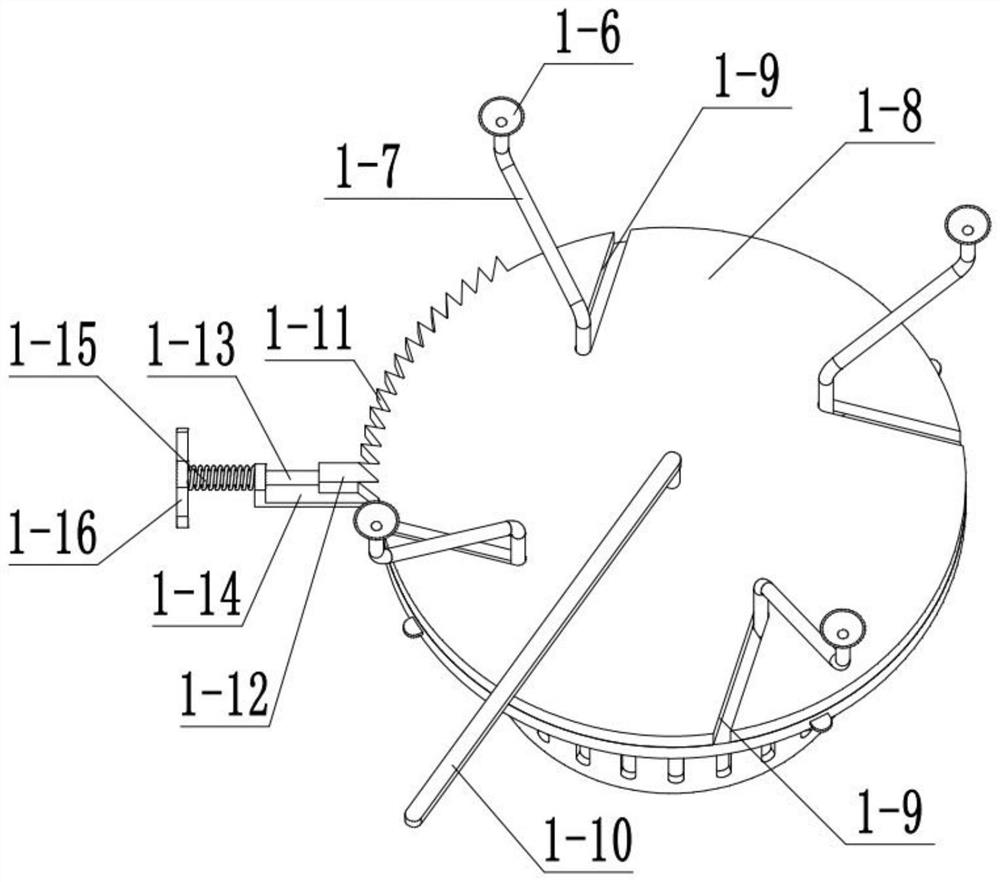

[0027] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain the first embodiment, the support adjustment assembly 1 includes a bottom plate 1-1, a pillar 1-2, an upper strut 1-3, a fan blade cover 1-4, and an air vent 1 -5. Support cover 1-6, suction pipe 1-7, turntable 1-8, chute 1-9, rotating rod 1-10, ratchet 1-11, limit card 1-12, slide bar 1-13, Slider bracket 1-14, spring Ⅰ 1-15, handle 1-16, suction pipe chute 1-17, sealing plate 1-18, spring Ⅱ 1-19, suction channel 1-20, motor Ⅰ 1-21, motor Ⅰ shaft 1-22, fan blade 1-23, motor bracket 1-24, lug 1-25, chute plate 1-26 and inclined plate 1-27, bottom plate 1-1 is connected with pillar 1-2, and pillar 1- 2 is connected with the upper pole 1-3, the bottom plate 1-1 is connected with the blade cover 1-4, the fan blade cover 1-4 is provided with a vent 1-5, the support cover 1-6 is connected with the suction pipe 1-7 The support cover 1-6 is made of soft rubber, the suction pipe 1-7 is sl...

specific Embodiment approach 3

[0028] Combine below Figure 1-12 This embodiment will be described. This embodiment will further illustrate the first embodiment. The cutting assembly 2 includes a double-head motor 2-1, a double-head motor shaft 2-2, a gap gear 2-3, a toggle gear 2-4, Toggle gear shaft 2-5, disk 2-6, disk lever 2-7, connecting rod 2-8, lifting frame 2-9, servo motor 2-10, electric cylinder 2-11, electric cylinder plate 2 -12, sliding plate 2-13, fixed cylinder 2-14, fixed cylinder clip 2-15, clamping plate 2-16, push-out column 2-17, heating thread cylinder 2-18 and melting cutter 2-19, double-headed The motor 2-1 is connected with the motor bracket 1-24, the double-head motor 2-1 is connected with the double-head motor shaft 2-2, the double-head motor shaft 2-2 is rotationally connected with the lug 1-25, and the double-head motor shaft 2-2 is connected with notch gear 2-3, notch gear 2-3 is meshed with toggle gear 2-4, and notch gear 2-3 has the same number of teeth as toggle gear 2-4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com