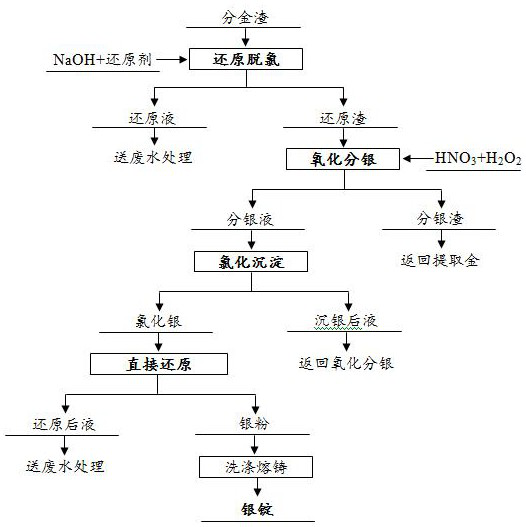

Method for extracting silver from gold separating residues

A technology for separating gold slag and silver chloride, applied in the direction of improving process efficiency, etc., can solve the problems of difficult ammonia-containing wastewater treatment, low production efficiency, and strong ammonia irritation, and achieve low production costs, low labor intensity, The effect of efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1

[0032] The main ingredients of the split slag are (%): AG53.0, AU0.8, PB3.5 and SB1.8. Both sodium hydroxide, nitric acid, sulfuric acid, hydrochloric acid are analyzed by analyzing pure reagents. The mass content of sodium hydroxide is not less than 96.0%. The mass concentration of nitric acid is not less than 65.0%, and the mass concentration of sulfuric acid is not less than 98.0. %, The mass concentration of the hydrogen peroxide is not less than 31.0%, and the hydrochloric acid mass is not less than 36.0%. Analysis of the mass content of pure hydrazine hydrazine was not less than 80%; the mass content of pure formaldehyde was not less than 37%.

[0033]Putting the golden residue, sodium hydroxide and water is slurried from 1: 0.3:2.5 in solid ratio (solid weight kg and solution volume L), thoroughly stirred with weight, and slowly add 10% hydrazine hydrazine, maintain temperature.The reaction was 1.0 h at 80 ° C, and the slurry was separated by vacuum filtr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap