Hectometer-level ultra-deep underground diaphragm wall body quality drilling coring detection method

A technology of drilling core and detection method, which is applied in the test of infrastructure, construction, infrastructure engineering, etc., can solve the problems of structural damage and low construction efficiency of underground diaphragm walls, and achieves less structural damage and drilling detection efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. These embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the content taught by the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope of the present invention. The scope of the application is defined by the appended claims.

[0020] A method for detecting the quality of a hundred-meter-level ultra-deep underground diaphragm wall by drilling and coring the body of the present invention specifically includes the following steps:

[0021] (1) Embedded steel pipe

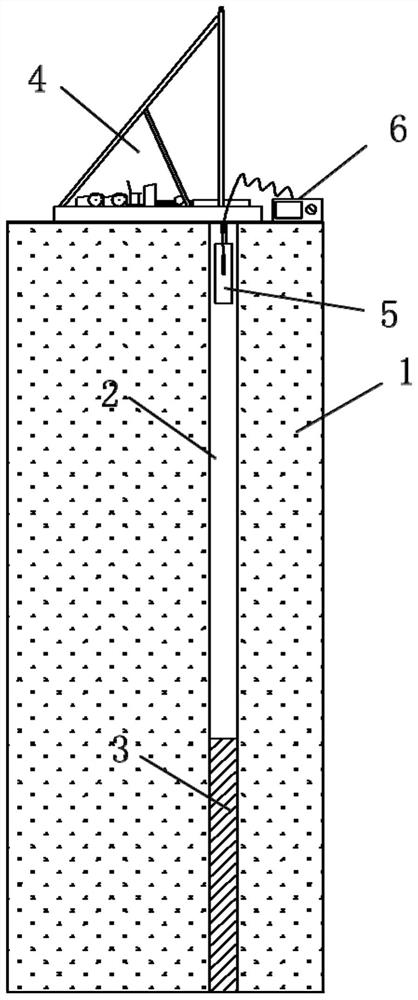

[0022] Such as figure 1 As shown, the steel pipe 2 is pre-embedded in the ultra-deep underground diaphragm wall 1, and the steel pipe is lowered to the top of the section 3 that needs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com