Anesthetic needle

A technology of anesthesia needles and syringes, applied in the field of anesthesia needles, which can solve the problems of sharp anesthesia needles, puncture medical staff, and poor safety, and achieve the effect of easy use and storage, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

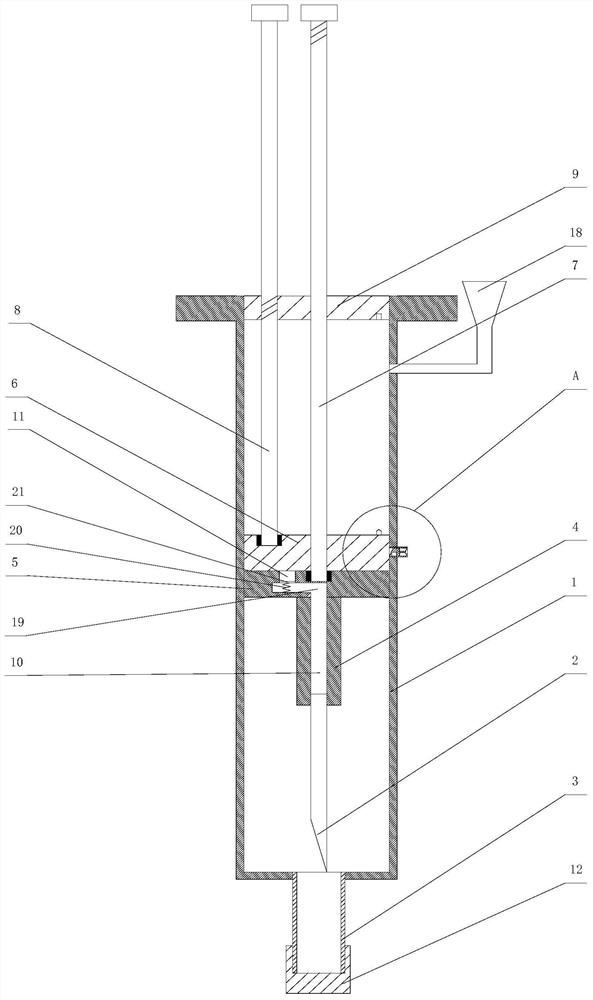

[0024] Such as figure 1 As shown, an anesthesia needle is provided in this embodiment, including a syringe 1 and a needle head 2, the top of the syringe 1 is closed by a closing plate 9, and the bottom of the syringe 1 has a needle hole, and the needle hole Connected to the outlet cylinder 3, the first piston 5 and the second piston 6 are all arranged in the needle cylinder 1, the first piston 5 and the second piston 6 are connected with the inner wall of the needle cylinder 1 in a sliding seal, the second piston 6 is located above the first piston 5, the top of the first piston 5 is connected with the first piston rod 7, the first piston rod 7 moves through the second piston 6 and the closing plate 9, between the first piston rod 7 and the second piston 6 Sliding seal, the top of the second piston 6 is connected with the second piston rod 8, the second piston rod 8 moves through the closing plate 9, the needle head 2 is fixed on the needle handle 4, and the needle handle 4 is...

Embodiment 2

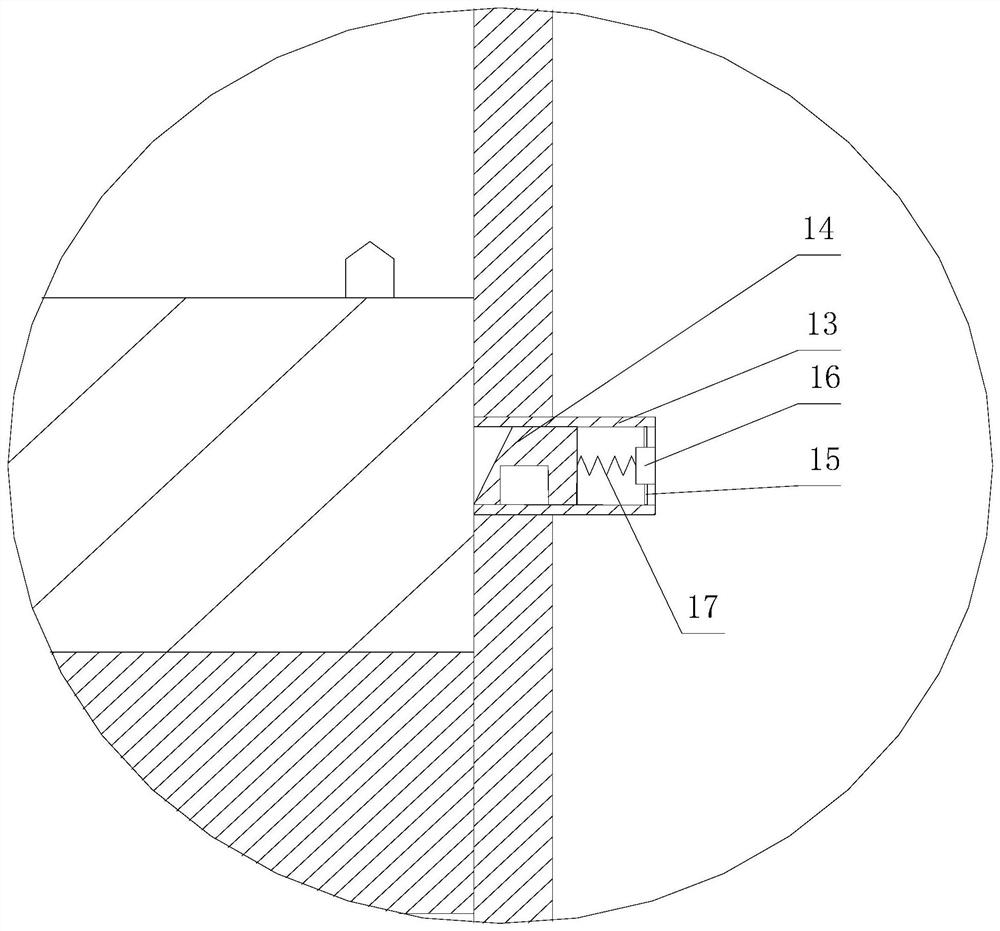

[0030] This embodiment is further limited on the basis of Embodiment 1. In this embodiment, the side wall of the syringe 1 is provided with a through hole, the through hole is connected with a containing tube 13, and the inner cavity of the containing tube 13 is in the shape of a cuboid , a blocking block 14 is slidably arranged in the containing tube 13, and the blocking block 14 can completely close the left end of the containing tube 13, and a fixing plate 16 is fixed in the containing tube 13 by a connecting rod 15, and the left wall of the fixing plate 16 is in contact with the blocking block 14. The right walls are connected by the first spring 17, and the left wall of the blocking block 14 is inclined downward as a whole in the direction from right to left. In the initial state, the second piston 6 is against the blocking block 14, so that the blocking block 14 is positioned at the receiving tube. 13, the first spring 17 is in a compressed state;

[0031] A liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com