Preparation process and processing method of milk powder capable of reducing blood sugar

A milk powder and sugar-lowering technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as difficult digestion and absorption, inability to lower blood sugar, uneven milk powder particles, etc., to achieve easy digestion and absorption, and benefit Processing and production, the effect of easy brewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

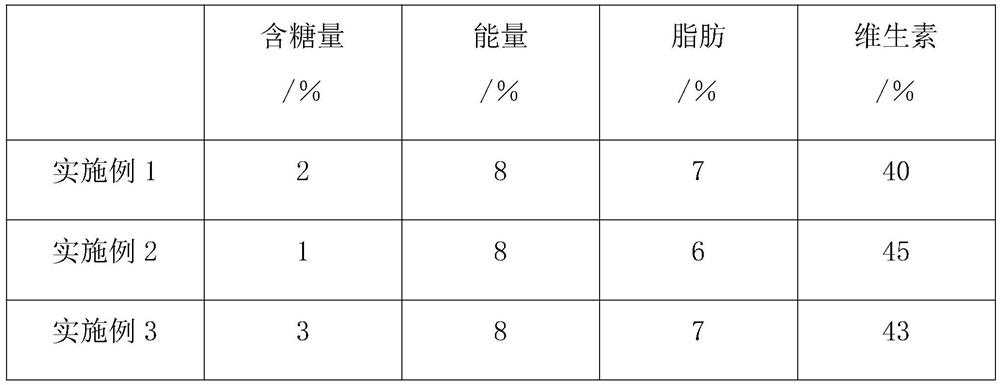

Embodiment 1

[0033] A hypoglycemic milk powder, the formula includes: raw milk, whole milk powder, desalted whey powder, concentrated whey protein powder, soybean oil, fructooligosaccharides, casein, calcium carbonate, vitamins and ferrous lactate, each component The mass percentages are: raw milk 16%, whole milk powder 20%, desalted whey powder 25%, whey protein concentrate powder 10%, soybean oil 4%, fructooligosaccharide 10%, casein 3% , calcium carbonate 10%, vitamin 1%, ferrous lactate 1% and zinc gluconate 1%.

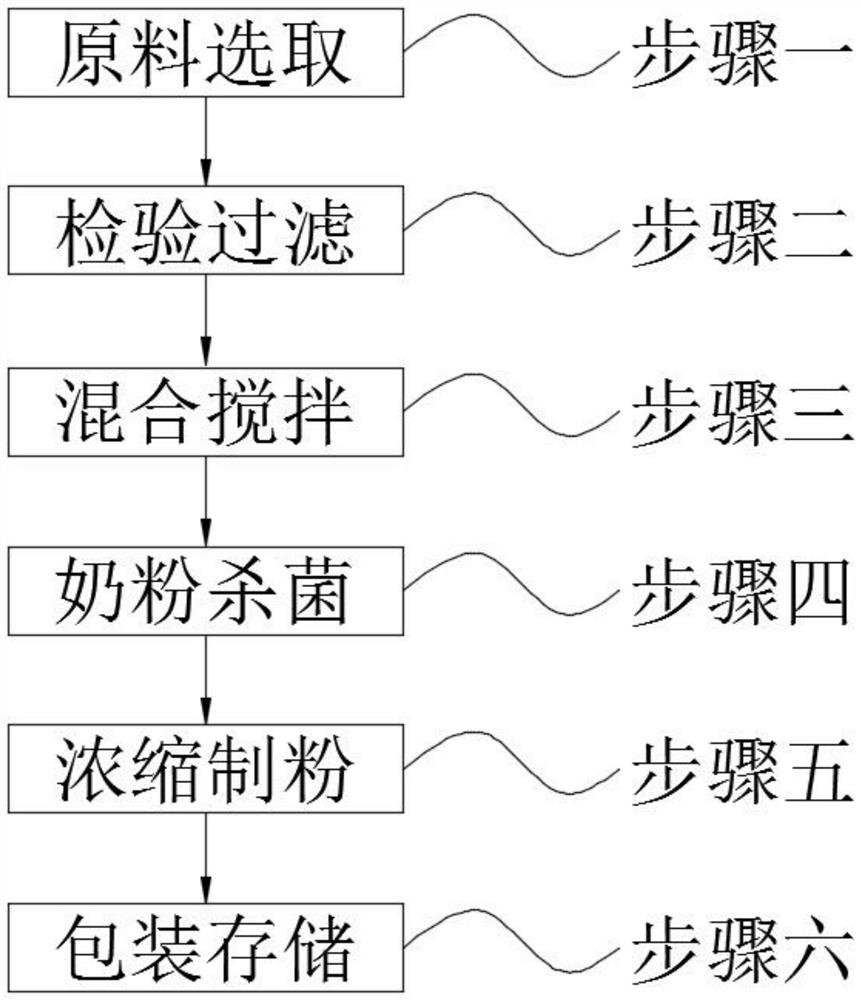

[0034] A processing method for the milk powder preparation process of hypoglycemic milk powder, comprising the following steps: Step 1, raw material selection; Step 2, inspection and filtration; Step 3, mixing and stirring; Step 4, milk powder sterilization; Step 5, concentrated powder making; Step 6 , packaging storage;

[0035] Wherein the above step 1, according to the mass percentage of each component is: raw milk 16%, whole milk powder 20%, desalted whey powder 25%, con...

Embodiment 2

[0053] A hypoglycemic milk powder, the formula includes: raw milk, whole milk powder, desalted whey powder, concentrated whey protein powder, soybean oil, fructooligosaccharides, casein, calcium carbonate, vitamins and ferrous lactate, each component The mass percentages are: raw milk 16%, whole milk powder 25%, desalted whey powder 20%, whey protein concentrate powder 10%, soybean oil 4%, fructooligosaccharide 10%, casein 3% , calcium carbonate 10%, vitamin 1%, ferrous lactate 1% and zinc gluconate 1%.

[0054] A processing method for the milk powder preparation process of hypoglycemic milk powder, comprising the following steps: Step 1, raw material selection; Step 2, inspection and filtration; Step 3, mixing and stirring; Step 4, milk powder sterilization; Step 5, concentrated powder making; Step 6 , packaging storage;

[0055] Wherein in the above-mentioned step 1, according to the mass percentage of each component, they are: 16% of raw milk, 25% of whole milk powder, 20%...

Embodiment 3

[0073] A hypoglycemic milk powder, the formula includes: raw milk, whole milk powder, desalted whey powder, concentrated whey protein powder, soybean oil, fructooligosaccharides, casein, calcium carbonate, vitamins and ferrous lactate, each component The mass percentages are: raw milk 16%, whole milk powder 30%, desalted whey powder 15%, whey protein concentrate powder 10%, soybean oil 4%, fructooligosaccharide 10%, casein 3% , calcium carbonate 10%, vitamin 1%, ferrous lactate 1% and zinc gluconate 1%.

[0074] A processing method for the milk powder preparation process of hypoglycemic milk powder, comprising the following steps: Step 1, raw material selection; Step 2, inspection and filtration; Step 3, mixing and stirring; Step 4, milk powder sterilization; Step 5, concentrated powder making; Step 6 , packaging storage;

[0075] Wherein the above step 1, according to the mass percentage of each component is: raw milk 16%, whole milk powder 30%, desalted whey powder 15%, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com