Coolant circulating filter system for enameled wire copper core drawing and using method thereof

A technology of circulating filtration and cooling liquid, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of easy clogging of wire drawing dies, affecting the quality of enameled wires, and different sizes of copper cores, so as to improve the processing quality and circulation. Environmentally friendly and efficient operation, stable and uniform processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

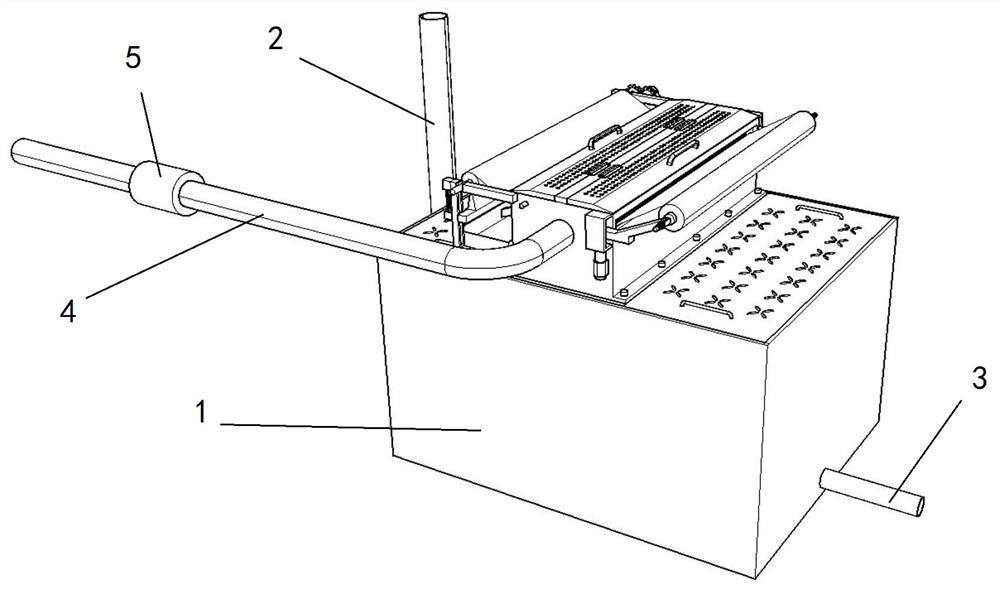

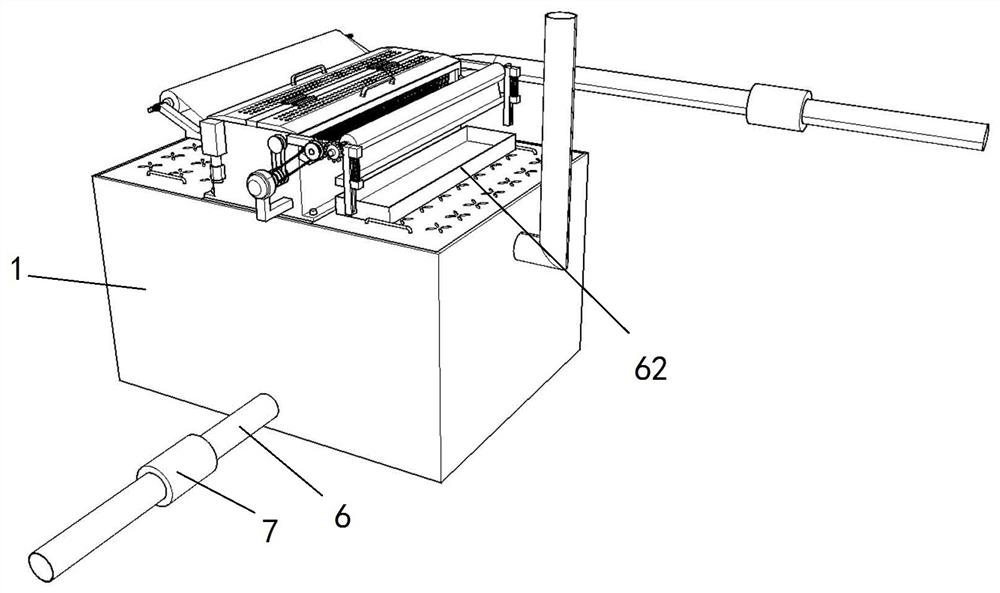

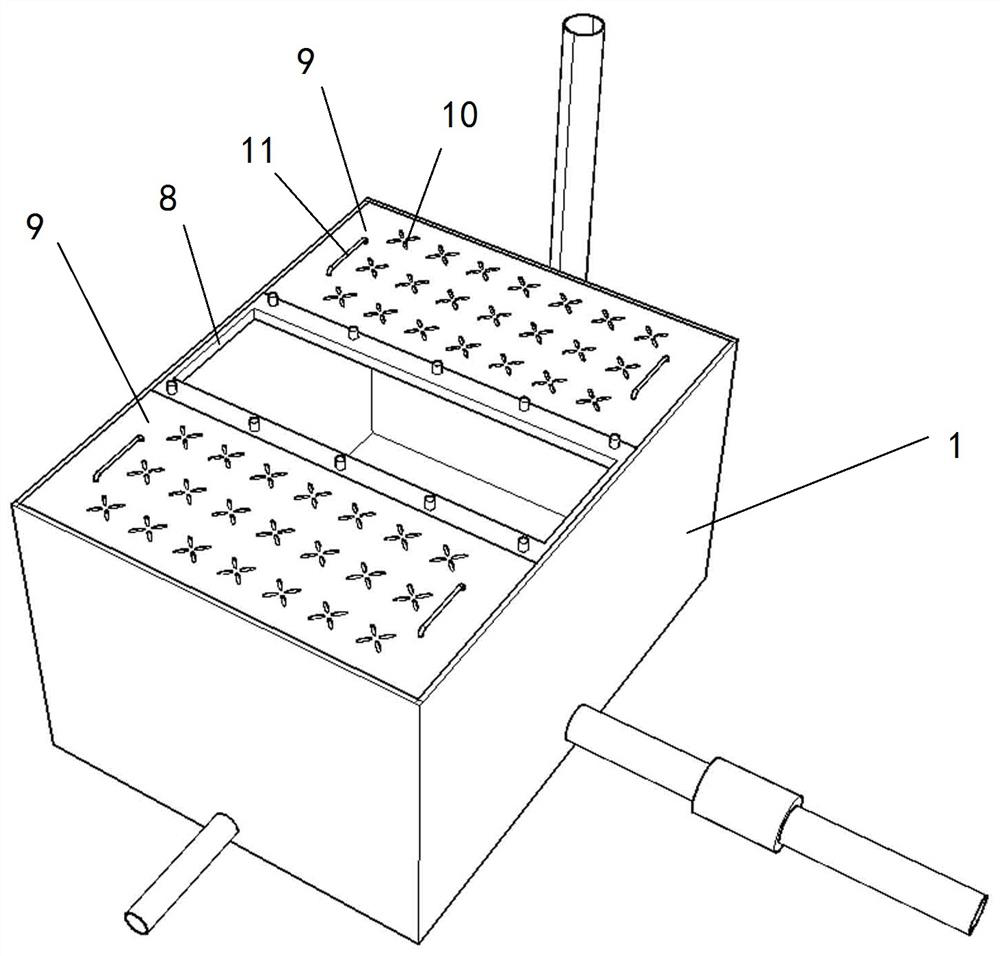

[0035] like Figure 1-13 , the cooling liquid circulation filtering system for enameled wire copper core drawing includes a circulation box 1, and the circulation box 1 is provided with a liquid injection pipe 2, a liquid outlet pipe 3, a liquid supply pipe 6, an installation frame 8 and a plurality of top covers 9. The installation frame 8 is provided with a filter structure, the filter structure is connected with the liquid return pipe 4, the liquid return pipe 4 is provided with a first water pump 5, and the liquid feed pipe 6 is provided with a second water pump 7;

[0036] The filter structure includes a casing 12 arranged on the mounting frame 8, the casing 12 is provided with a feed port 13, a discharge port 14 and a skeleton 15, the skeleton 15 is connected with the cover plate 17 through the hinge structure 16, and the casing 12 is The position of the feeding port 13 is provided with a discharging structure that cooperates with the filter paper, the position of the di...

Embodiment 2

[0046] like Figure 1-13 In, the using method of the present invention is:

[0047] 1. Start the motor 27 before use, cooperate with the filter screen 22 to rotate at the position of the discharge port 14 to clean it, and keep the filter screen 22 free of impurities;

[0048] 2. Inject the cooling liquid required for the circulation through the liquid injection pipe 2, then put the filter paper tube on the feeding roller 35, put it into the discharging structure, and feed the end of the filter paper on the filter paper tube through the feeding The outlet 13 and the multiple groups of guide rollers 21 are drawn out from the outlet 14, and are fixed with the take-up roller 52;

[0049] 3. Then rely on the liquid return pipe 4 and the liquid feeding pipe 6 to communicate with the cooling liquid inlet and outlet of each wire drawing device through the pipeline system respectively, so as to realize the smooth circulation of the cooling liquid pipeline, and then start the motor 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com