Preparation method of Co3O4 particle-loaded nanocarbon composite catalytic material

A technology of nano-carbon materials and catalytic materials, which is applied in the preparation of nano-carbon composite catalytic materials and the field of sewage degradation treatment, can solve the problems of complex process, low efficiency, long process time, etc. The effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

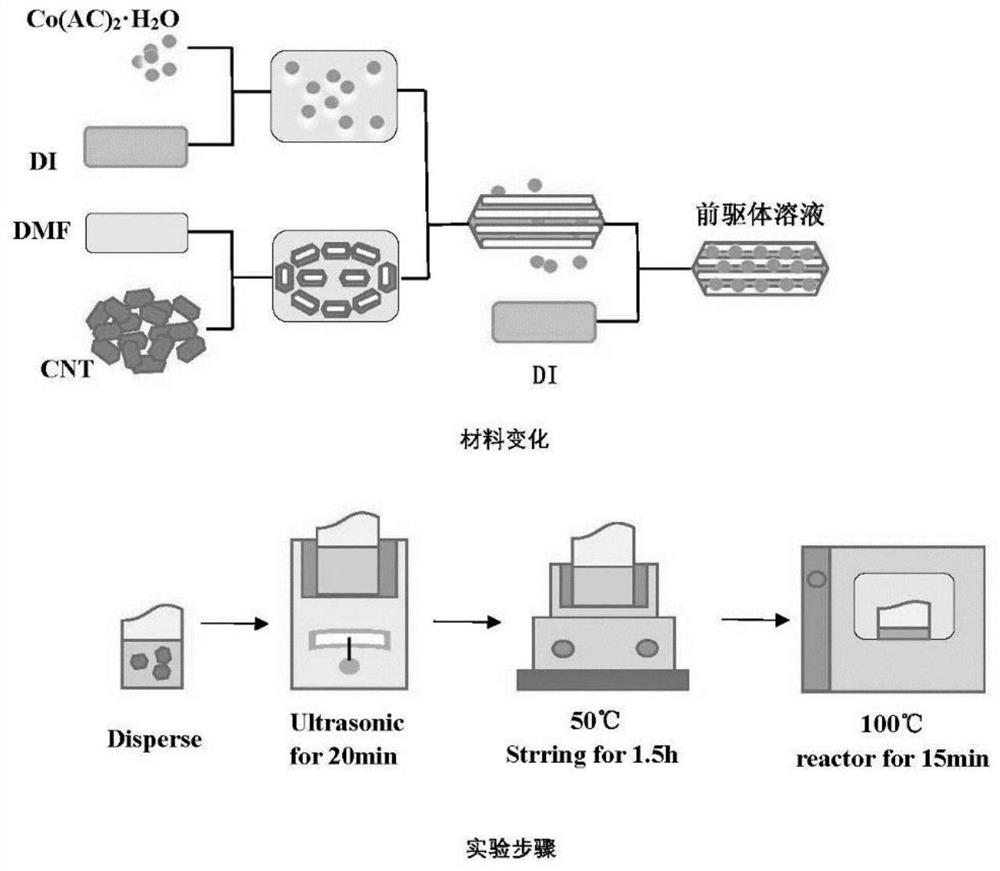

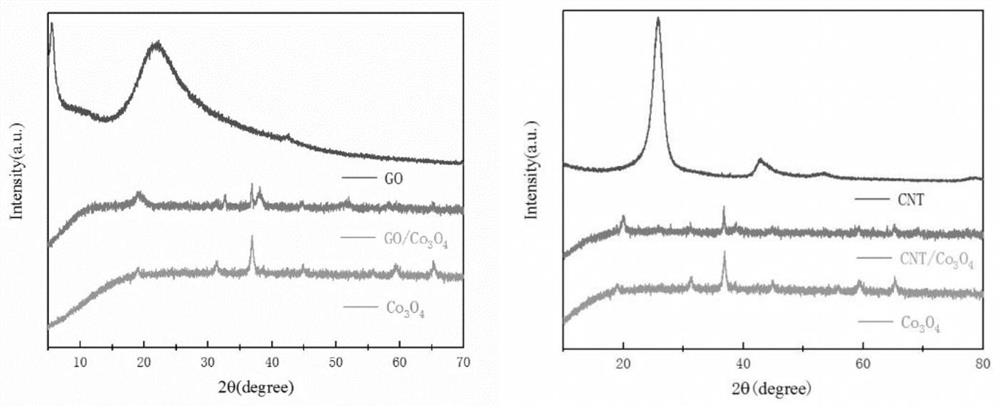

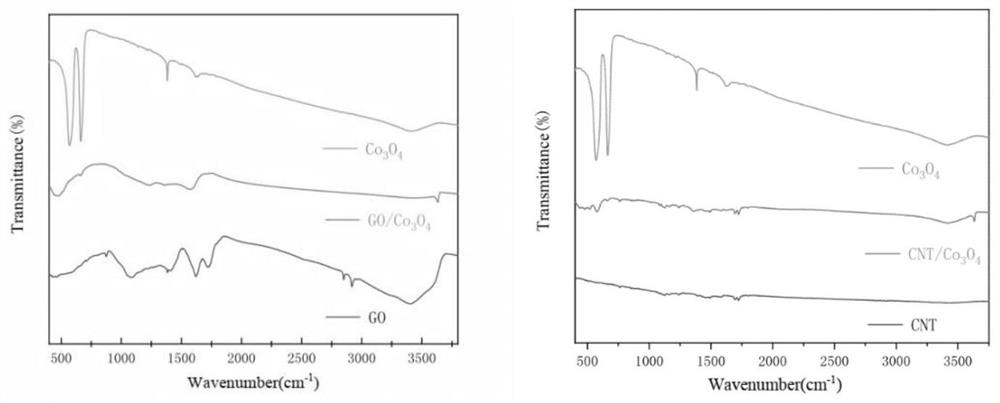

[0028] Load C on nanocarbon material (GO) O3 O 4 Composite catalytic material, with GO as carrier materials, C O3 O 4 For attachment materials, it is prepared by step-by-step microwave hydrothermal. The specific preparation method includes the following steps:

[0029] (1) Pre-treatment: After the weighing 5 mg GO (about 3.3 mg of C is about 3.3 mg of GO) and 20 ml of DMF, it is placed in ultrasonic instruments, and 2 ml of deionized water and 0.1 g of four water were added dropwise. Cobalt acetate mixed solution to form a precursor solution;

[0030] (2) Step-by-step microwave hydrothermal method: Put the precursor solution at a speed of 300 rpm at a speed of 300 rpm in a magnetic stirring water bath, resulting in an intermediate product; 50 mg intermediate product is filtered after filtering with ethanol, add 5ml The ionized water is subjected to secondary dispersion, and the dispersed solution is placed in a microwave parallel water heat synthesizer at 100 ° ...

Example Embodiment

[0036] Example 2

[0037] Example 2 differs from the embodiment described in Example 1 in that: changing only the parallel microwave synthesizer hydrothermal reaction temperature was 120 ℃. The resulting GO / Co 3 O 4 Composite catalytic material, the nano-C O3 O 4 The supporting structure exactly the same, to increase the particle size diameter 50-120nm.

[0038] Photocatalytic performance tests, the composite catalyst prepared in Example 2 of the embodiment greater than 90% of the Orange Ⅱ degradation removed within 0.5h.

Example Embodiment

[0039] Example 3

[0040] A load C in the nano-carbon material (CNT) O3 O 4 The composite catalytic material to the carrier material for the CNT, C O3 O 4 For attachment materials, it is prepared by step-by-step microwave hydrothermal. The specific preparation method includes the following steps:

[0041] (1) Prior to Treatment: After weighing 5mg CNT according 20ml DMF and mixed at room temperature in a thermostat placed in an ultrasonic apparatus the ultrasonic 0.5h, 2ml was added dropwise a mixed solution of deionized water and 0.1g of water four cobalt acetate, forming a precursor solution;

[0042] (2) Step-by-step microwave hydrothermal method: Put the precursor solution at a speed of 300 rpm at a speed of 300 rpm in a magnetic stirring water bath, resulting in an intermediate product; 50 mg intermediate product is filtered after filtering with ethanol, add 5ml The ionized water is subjected to secondary dispersion, and the dispersed solution is placed in a microwave paralle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap