Plasma arc fusion brazing method for thin-wall stainless steel and thin-wall red copper

A plasma arc and stainless steel technology, used in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of high welding cost and high silver content of silver-based copper wire, achieve convenient operation, reduce welding difficulty, and meet the needs of the process. Requirements and Effects of Using Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

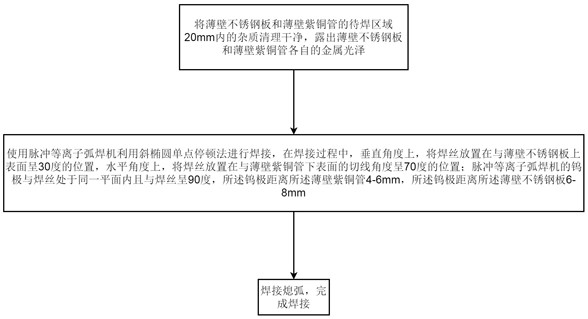

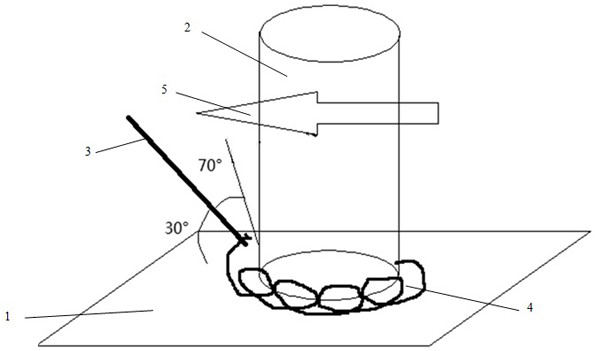

[0023] Please refer to the attached Figure 1-2 , the technical problem to be solved in this embodiment is that, at the present stage, the filling material silver-based copper welding wire for the copper tube-stainless steel tube-sheet fillet joint technology in China has a high silver content, resulting in high welding costs. For the plasma arc melting brazing method of thin-walled stainless steel and thin-walled red copper, the plasma arc melting brazing method for thin-walled stainless steel and thin-walled red copper comprises:

[0024] Clean up the impurities within 20mm of the thin-walled stainless steel plate and thin-walled copper tube to be welded to expose the respective metallic luster of the thin-walled stainless steel plate and thin-walled copper tube;

[0025] Use the pulse plasma arc welding machine to weld with the oblique ellipse single-point pause method. During the welding process, the welding wire is placed at a position 30 degrees from the surface of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap