Mixed fatty acid for removing vanadium from high-vanadium-content crude titanium tetrachloride and vanadium removal method

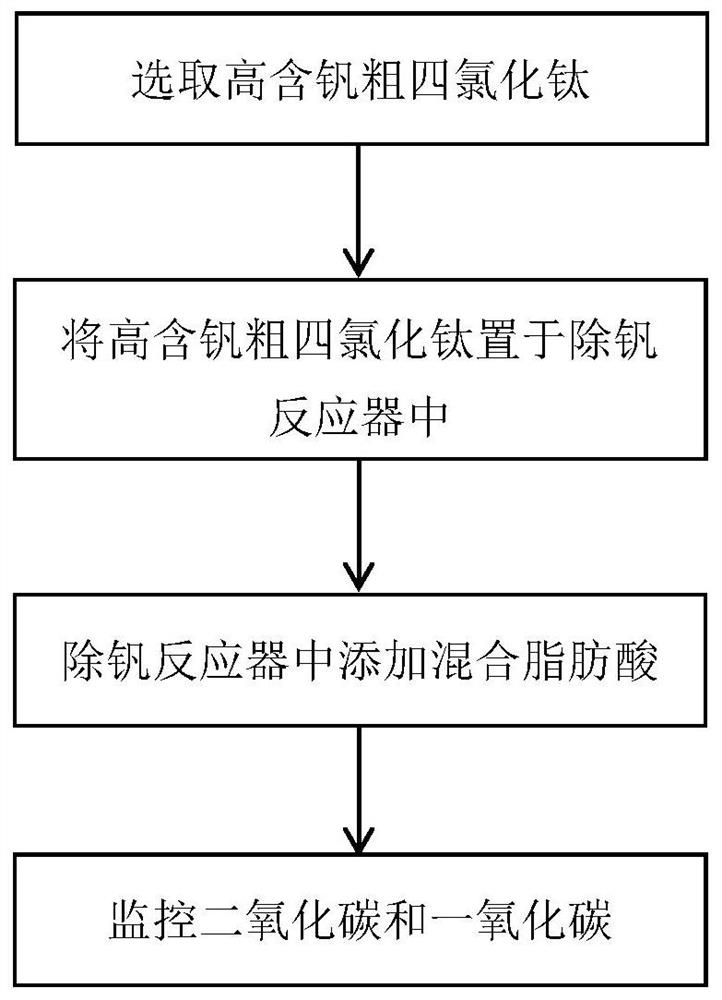

A technology of crude titanium tetrachloride and mixed fatty acids, which is applied in the direction of titanium tetrachloride and titanium halide, and can solve the problems of unfavorable application treatment, sticky tailing residue of vanadium removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Select the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride, wherein the molar content of vanadium oxytrichloride in the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride is 1.65%; select oleic acid and palmitic acid for deployment Mixed fatty acid, the molar ratio of carbon-carbon double bond and α-H and carboxyl in the mixed fatty acid of deployment is: carbon-carbon double bond: (α-H and carboxyl)=0.75; Titanium chloride is placed in the vanadium removal reactor, and the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride in the vanadium removal reactor is heated by a heater, and the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride is The temperature of titanium rises to 120°C at 20°C / min; add mixed fatty acid to the vanadium removal reactor, the amount of mixed fatty acid added is based on the amount of mixed fatt...

Embodiment 2

[0036]Select the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride, wherein the molar content of vanadium oxytrichloride in the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride is 1.65%; select oleic acid and palmitic acid for deployment Mixed fatty acid, the molar ratio of carbon-carbon double bond and α-H and carboxyl in the mixed fatty acid of deployment is: carbon-carbon double bond: (α-H and carboxyl)=0.6; Titanium chloride is placed in the vanadium removal reactor, and the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride in the vanadium removal reactor is heated by a heater, and the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride is The temperature of titanium rises to 120°C at 20°C / min; add mixed fatty acid to the vanadium removal reactor, the amount of mixed fatty acid added is based on the amount of mixed fatty ...

Embodiment 3

[0038] Select the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride, wherein the molar content of vanadium oxytrichloride in the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride is 1.09%; select oleic acid and palmitic acid for deployment Mixed fatty acid, the mol ratio of carbon-carbon double bond and α-H and carboxyl in the mixed fatty acid of deployment is: carbon-carbon double bond: (α-H and carboxyl)=0.7; Titanium chloride is placed in the vanadium removal reactor, and the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride in the vanadium removal reactor is heated by a heater, and the high vanadium-containing crude titanium tetrachloride containing vanadium oxytrichloride is The temperature of titanium rises to 115°C at 10°C / min; add mixed fatty acid to the vanadium removal reactor, the amount of mixed fatty acid added is based on the amount of mixed fatty a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com