Steel bar connecting structure

A technology for connecting structures and steel rods, which is applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems of joint damage, weld fracture, fracture, etc., and achieve the effect of achieving stability and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example

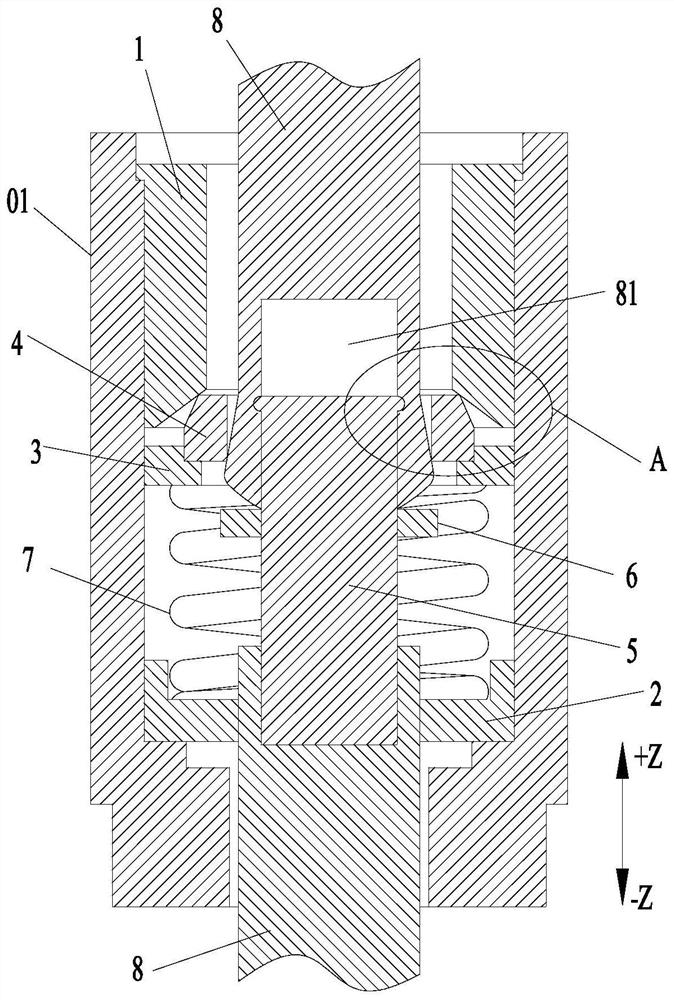

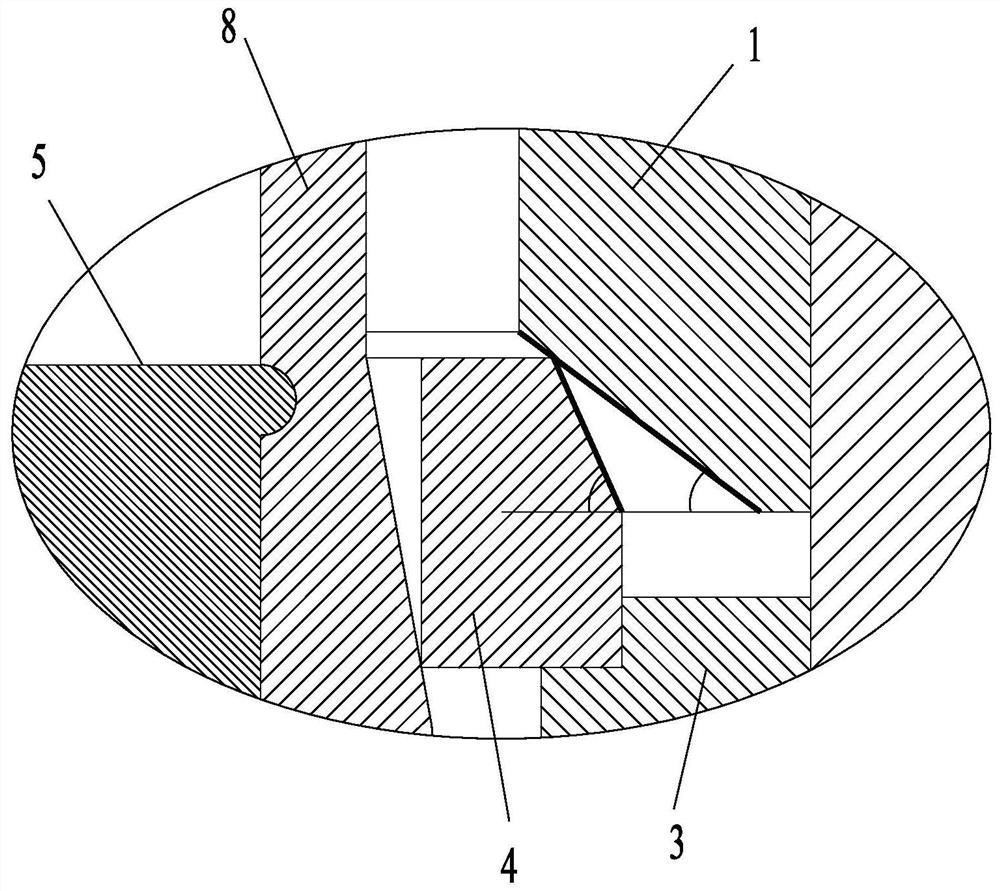

[0034] like figure 1 As shown, the present invention provides a steel rod connection structure, and the similar end of the two steel rods 8 is fixed by the connection structure, and specifically includes a base set 01 disposed within the base 02;

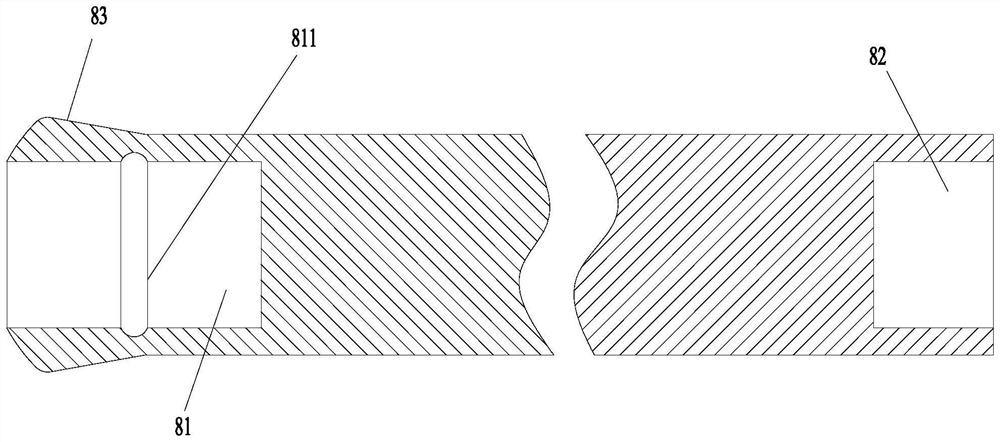

[0035] Among them, the base 02 is a prefabricated concrete, such as Figure 7 As shown, the connection structure is uniformly distributed in a circumferential direction, or can also be set separately on the base 02, which can be set according to the actual situation.

[0036] The first adjusting pad 2, spring 7, the second adjustment pad 3, the cassette 4, and the locking sleeve 1 are sequentially provided in the base set 01;

[0037] The inner wall of the base set 01 is ladder, and the first adjusting pad 2 is adjusted at the step of the base set 01, and is fixed to the end portion of the steel rod 8, for example, by the threaded connection, thereby restricting the first adjustment pad. 2 displacement in a direction axi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap