High-temperature calcium carbide forced heat exchange system

A heat exchange system and calcium carbide technology, applied in the field of energy saving and emission reduction, can solve the problems of heat energy waste, slow cooling of high temperature calcium carbide, etc., and achieve the effects of convenient use, accelerated heat energy dissipation, and easy maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1

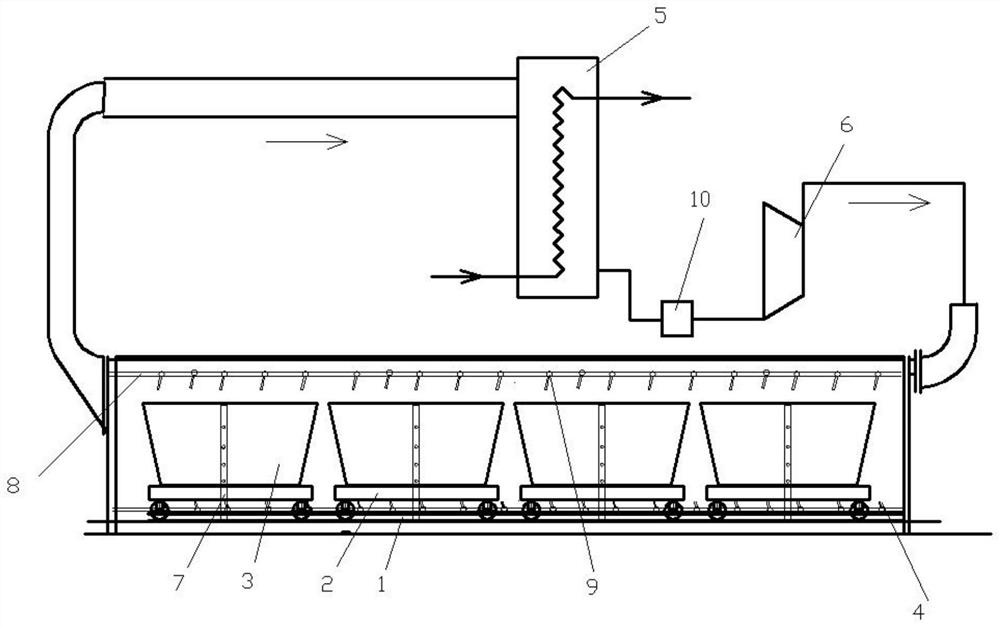

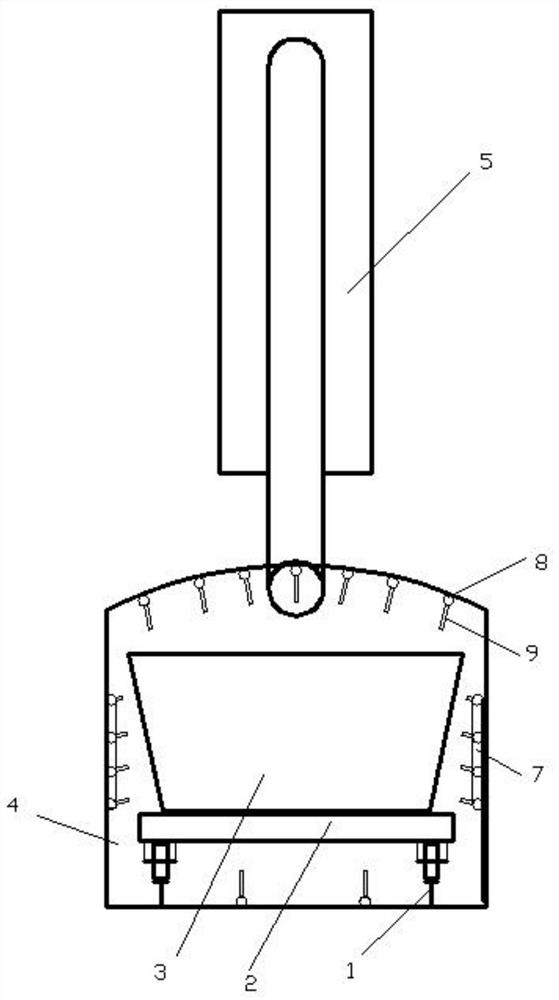

[0035] like Figure 1 to 2 , The present embodiment is designed to force a high-temperature heat transfer system of the calcium carbide, comprising a heat recovery kiln 4, the electric Kamameshi 3, the blower fan 6, the cold wind, the jet nozzle 9 and blowing the heat exchanger 5 and the like structures.

[0036] Kiln heat recovery chamber 4 is provided with a kiln; the thermal energy recovery kiln wall 4 having insulation function; the thermal energy recovery chamber in kiln 4 is a channel-shaped arch structure, before and after wear and, in the kiln chamber both ends of the kiln are provided with a feed inlet and a kiln, provided with switchable kiln entrance into the kiln and in the kiln mouth. When the high-temperature heat transfer process in forced carbide, kiln door will close.

[0037]Ground calcium carbide kiln chamber layered with a rail car, and the car calcium carbide to the outer rail 1 extends thermal energy recovery kiln 4; 1 rail vehicle on calciu...

Example Embodiment

[0046] Example 2

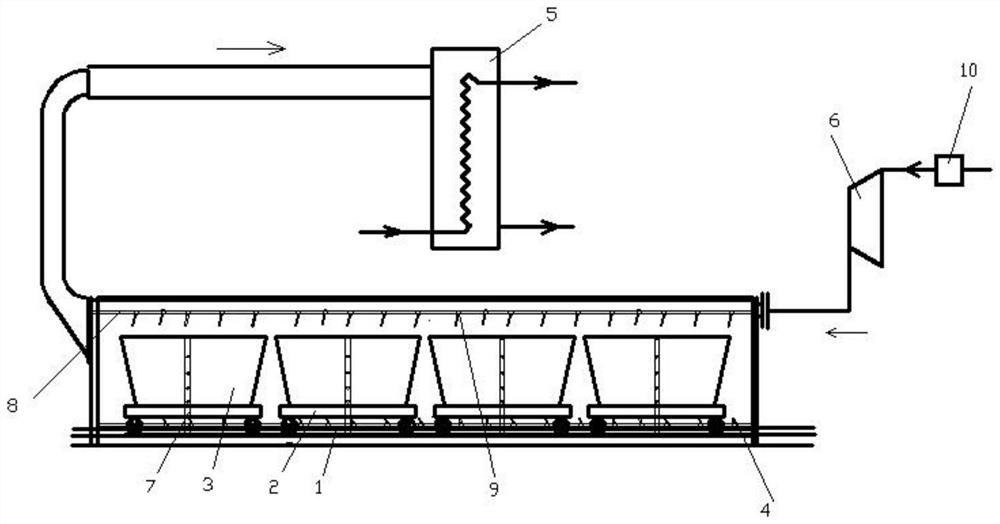

[0047] like Figure 3 to 4 , The present embodiment is designed to force a high-temperature heat transfer system of the calcium carbide, comprising a heat recovery kiln 4, the electric Kamameshi 3, the blower fan 6, the cold wind, the jet nozzle 9 and blowing the heat exchanger 5 and the like structures.

[0048] Heat recovery furnace in the present embodiment in Example 4 the same structure 1, and the tube and jet nozzle in the cold provided 4 heat recovery kiln is also the same as in Example 1 arrangement 9, at the same time, the present embodiment the heat exchanger structure may be used in the embodiment of Example 1, other configurations may be used, when installing the heat exchanger, which will be higher than the height of the mounting position of the heat absorbing heat recovery kiln exhaust pipe 4.

[0049] Structure of this embodiment is designed in Example 1 except that the large: the blower without passing through the heat exchanger 5 through pipes di...

Example Embodiment

[0051] Example 3

[0052] The present embodiment is designed a method of producing a high temperature carbide, which Example 1 using the calcium carbide or by cooling the high temperature heat recovery carbide or calcium carbide as in Example 2 to force the heat exchange system embodiment.

[0053] Furnace calcium carbide production method is industrially used, coke and smelting in an electric furnace of calcium oxide, calcium carbide generated. At this time, the temperature of the baked carbide production furnace up to 1800 ℃ -2200 ℃. For instance, when the degree of calcium carbide furnace generally reached 2000 deg.] C, the specific heat capacity of 0.264 kcal / kg.℃, i.e. 1.1kJ / kg ℃, having a heat of 522.7 kcal / kg i.e. 2185kJ / kg. Conventional cooling method is the direct use of high temperature carbide electric winch or onto the trolley the cooling pot this row field, naturally cooled, the cooling process, the calcium carbide crusts from the inside outward strength to wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap