Drawstring bag production and manufacturing assembly line and manufacturing process method

A drawstring bag and assembly line technology, which is applied in drawstring bag production and manufacturing lines and manufacturing processes, can solve problems such as production efficiency, and achieve the effects of reducing production costs, improving precision and firmness, and strengthening firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

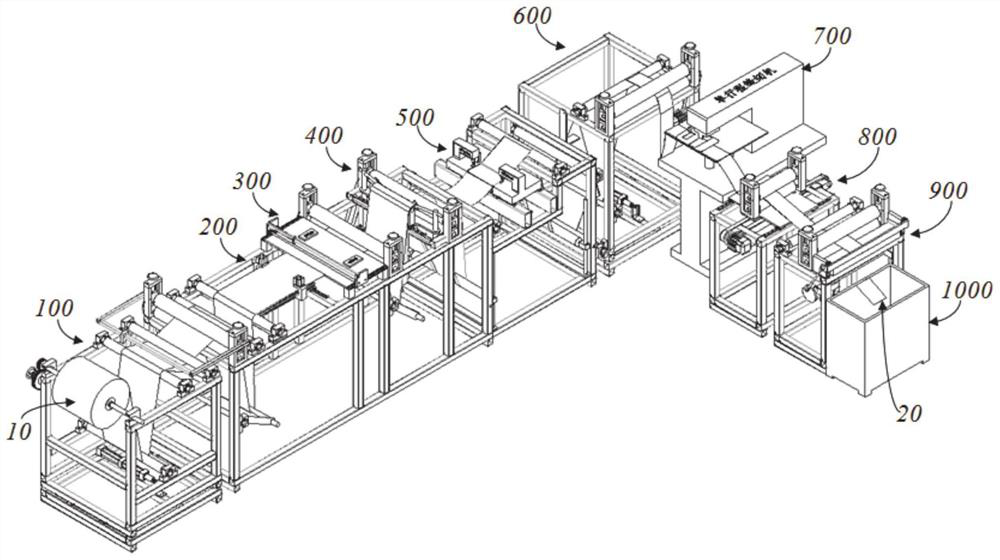

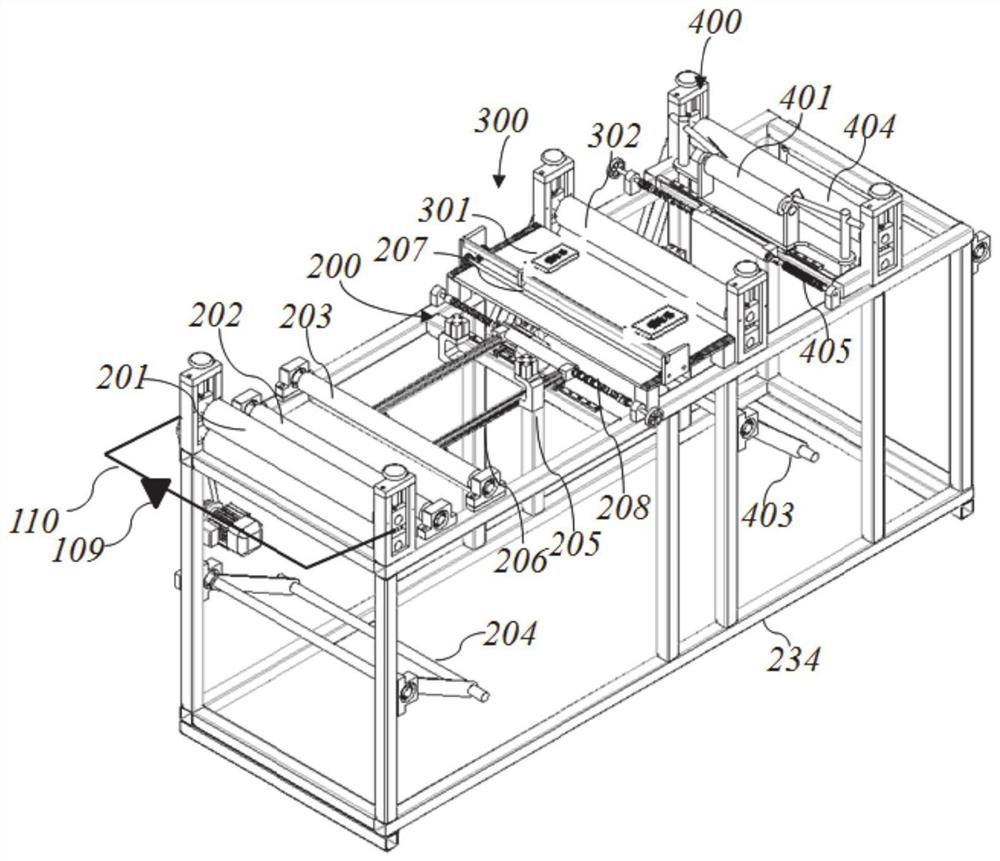

[0044] Such as figure 1 As shown, this embodiment provides a typical drawstring bag production line of the present disclosure, including a deviation correcting and discharging device 100, a positioning and punching device 200, an upper double edge hemming device 400, and an upper double edge sewing device 500 arranged in sequence. , a half-folding device 600, a double-thread sewing device 700, and a cutting device 900.

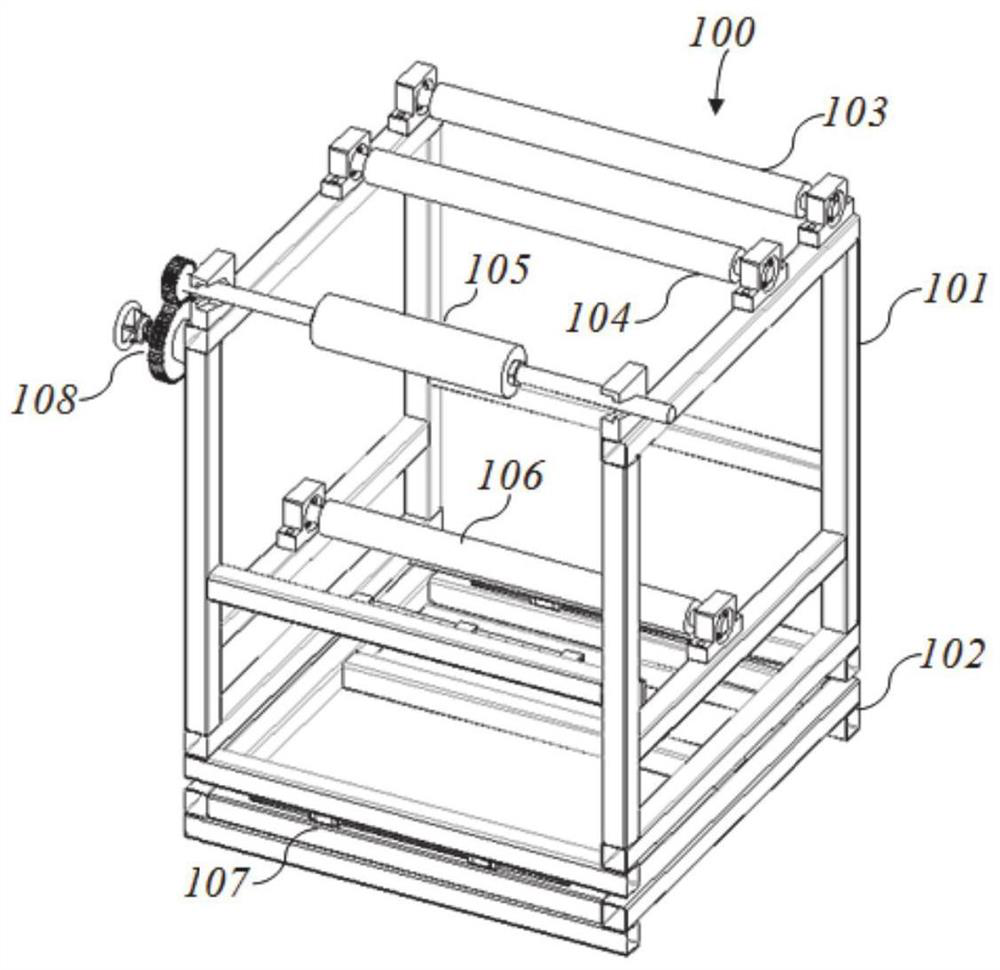

[0045] Such as figure 2 and image 3As shown, the deviation correction discharging device 100 includes a cloth edge recognizer, a first bracket 101, and a second bracket 102 located at the bottom of the first bracket 101, and the first bracket 101 and the second bracket 102 are slidingly connected; Guide rails are set on the two supports 102, and a slide block 107 is set on the first support 101. In addition, an air cylinder is set on the second support 102, which is not shown in the figure, and the telescopic end of the air cylinder is connected with the f...

Embodiment 2

[0077] This embodiment provides a manufacturing process based on the drawstring bag production line in Embodiment 1, including the following steps, such as Figure 10 Shown:

[0078] Step 1, set the width of the multiple edges of the fabric 10, that is, the distance between the edge of the fabric 10 and the inner fold line 12, print a number of color marks 11 on the multiple edges of the fabric 10, and set the distance between each color mark 11, such as Figure 10 As shown in (a), in this embodiment, the color scale 11 is preferably a rectangular color scale. The cloth 10 is placed in a roll on the first support, and the edge of the cloth 10 is recognized by the cloth edge recognizer, and then the material is corrected through the sliding connection between the first support 101 and the second support 102;

[0079] In step 2, the first color mark recognizer recognizes the color mark 11 and locates the punching position, and then utilizes the puncher 205 to manufacture holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com