Full-prefabricated bridge swing self-resetting damping structure system for inverted T-shaped bent cap

A self-resetting and beam-covering technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of easy slippage, less application of prefabricated piers, weak deformation ability, etc., to achieve rapid repair or replacement, and a wide range of engineering applications. , the effect of reducing the internal force response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

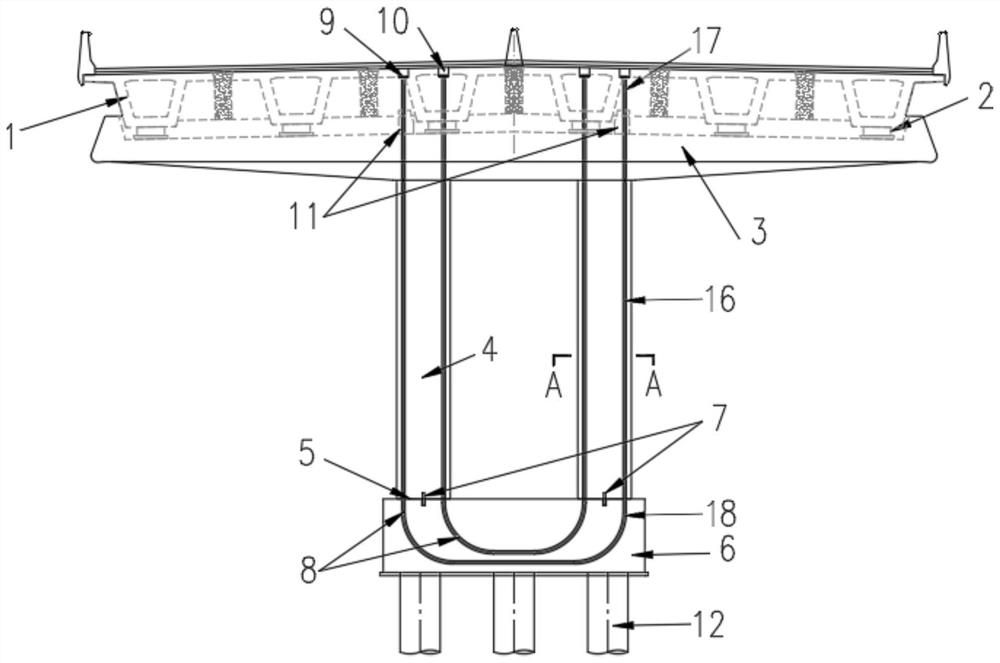

[0026] A fully prefabricated bridge swing self-resetting shock-absorbing structural system for inverted T-covered girders, such as Figure 1~2 As shown, it includes two groups of prefabricated main girders 1, prefabricated inverted T cover beams 3, caps 6, shear pins 7, prestressed steel tendons 8, two prefabricated bridge piers 4 and pile foundations 12.

[0027] Specifically, the main structure of the present invention is: the top surface of the pile foundation 12 is fixedly connected to the bottom surface of the cap 6, the prefabricated pier 4 is vertically arranged on the cap 6, and the bottom surface of the prefabricated inverted T cover beam 3 is respectively connected with two prefabricated The top surface of the bridge pier 4 is fixedly connected, and the two groups of prefabricated main girders 1 are respectively arranged on the shoulders on both sides of the prefabricated inverted T cover beam 3, and the prefabricated bridge pier 4, the prefabricated inverted T cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com