Canned meat raw material unfreezing equipment

A technology of canned meat and raw materials, which is applied in the field of thawing equipment for canned meat raw materials, can solve the problems of low degree of mechanization, high manual participation, complex and diverse procedures, etc., and achieve the effect of reducing human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

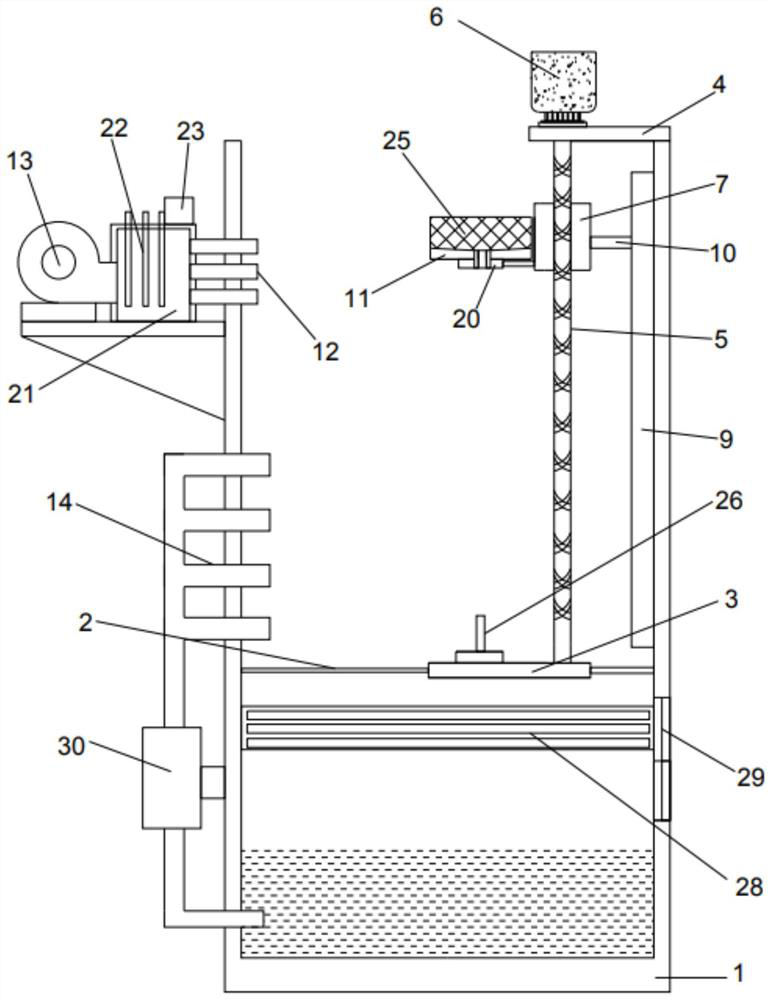

[0031] Embodiment 1: as figure 1 , the present invention provides a raw material thawing device for canned meat, comprising a cylinder 1 with an open upper end and a closed lower end, the cylinder 1 is provided with a transverse support rod 2, and the lateral support rod 2 is provided with a backing plate 3, the The top of the cylinder body 1 is provided with a transverse support plate 4, the transverse support plate 4 is opposite to the backing plate 3 up and down, a reciprocating screw rod 5 is arranged between the transverse support plate 4 and the backing plate 3, and on the transverse support plate 4 A motor 6 is provided, the drive shaft of the motor 6 is connected to the reciprocating screw mandrel 5, the reciprocating screw mandrel 5 is provided with a moving block 7, the moving block 7 is provided with a first perforation 8, and the reciprocating screw mandrel 5 is provided with a first perforation 8. 5 passes through the first perforation 8, the first perforation 8 i...

Embodiment 2

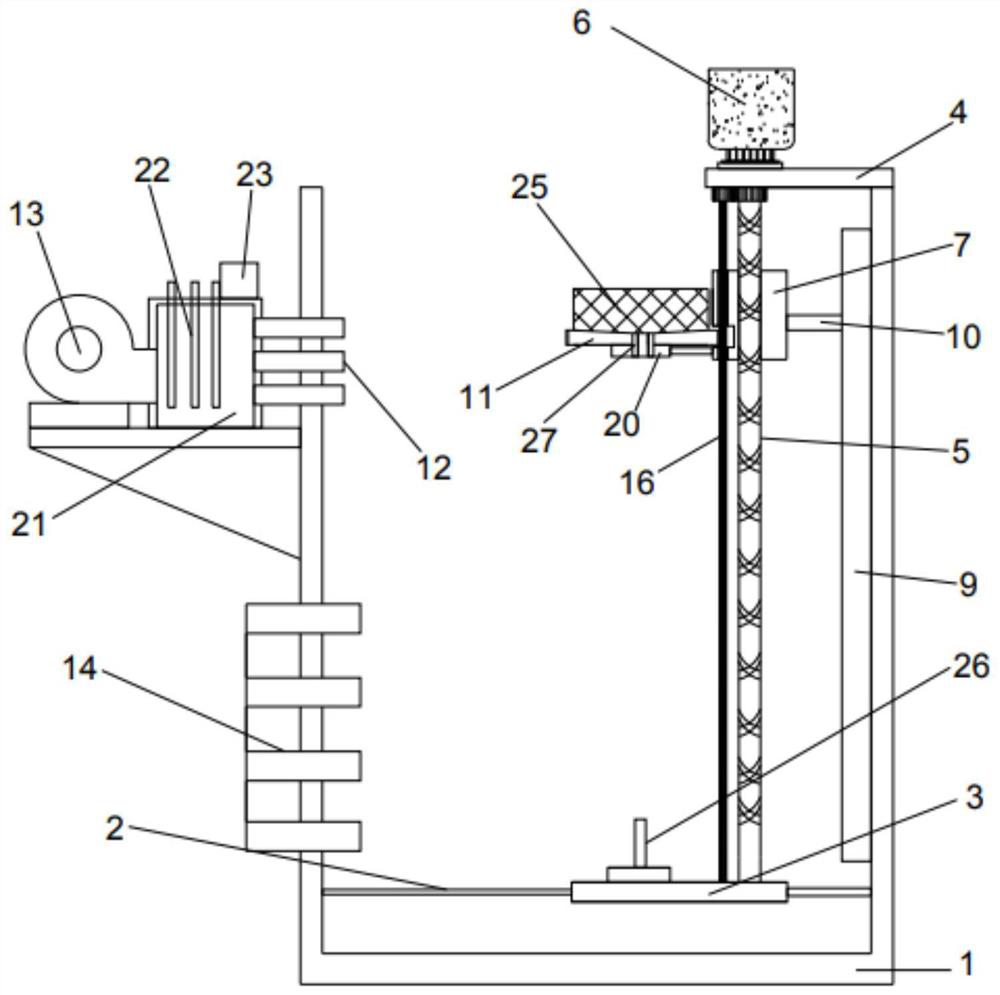

[0040] Embodiment 2: as figure 2, the present invention provides a raw material thawing equipment for canned meat, which is characterized in that: it includes a cylinder 1 with an open upper end and a closed lower end, and a horizontal support rod 2 is arranged inside the cylinder body 1, and a backing plate is arranged on the lateral support rod 2 3. The top of the cylinder body 1 is provided with a transverse support plate 4, the transverse support plate 4 is opposite to the backing plate 3 up and down, and a reciprocating screw rod 5 is arranged between the transverse support plate 4 and the backing plate 3, and the transverse support plate 4 and the backing plate 3 are provided with a reciprocating screw rod 5. The support plate 4 is provided with a motor 6, the drive shaft of the motor 6 is connected to the reciprocating screw mandrel 5, the reciprocating screw mandrel 5 is provided with a moving block 7, and the moving block 7 is provided with a first perforation 8, so ...

Embodiment 3

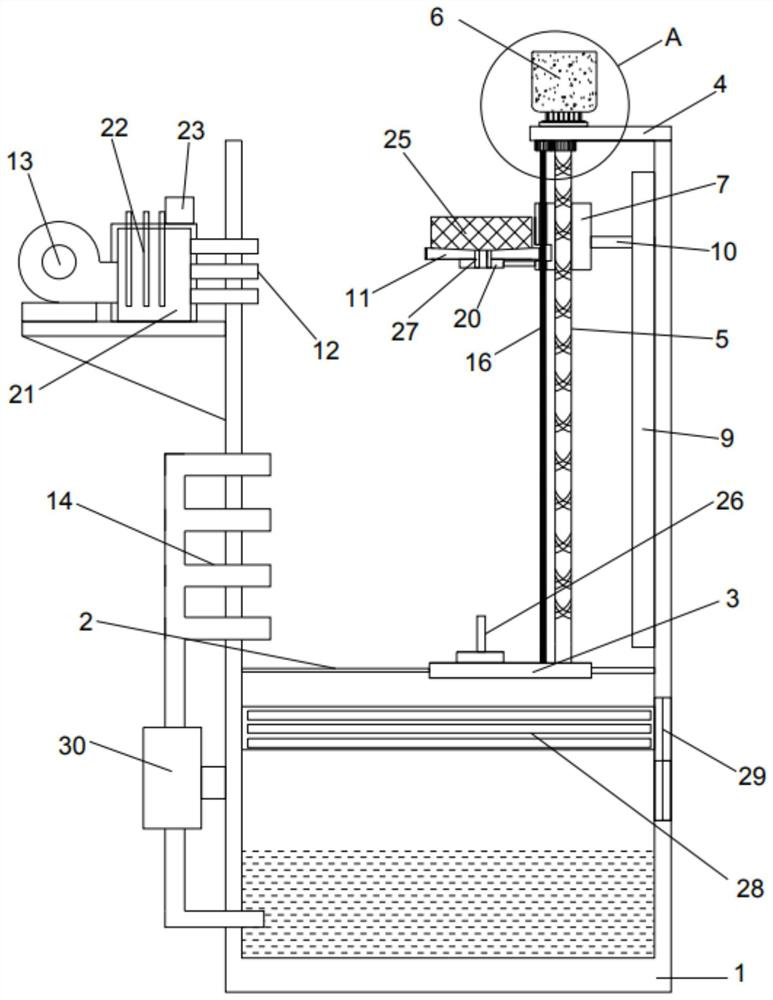

[0048] Embodiment 3: as Figure 3-8 , the present invention provides a raw material thawing device for canned meat, comprising a cylinder 1 with an open upper end and a closed lower end, the cylinder 1 is provided with a transverse support rod 2, and the lateral support rod 2 is provided with a backing plate 3, the The top of the cylinder body 1 is provided with a transverse support plate 4, the transverse support plate 4 is opposite to the backing plate 3 up and down, a reciprocating screw rod 5 is arranged between the transverse support plate 4 and the backing plate 3, and on the transverse support plate 4 A motor 6 is provided, the drive shaft of the motor 6 is connected to the reciprocating screw mandrel 5, the reciprocating screw mandrel 5 is provided with a moving block 7, the moving block 7 is provided with a first perforation 8, and the reciprocating screw mandrel 5 is provided with a first perforation 8. 5 passes through the first perforation 8, the first perforation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com