Treatment method of rhodium-containing catalyst and rhodium-containing catalyst

A technology of rhodium catalyst and treatment method, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, rhodium organic compounds, etc., can solve the problems of low recovery rate of rhodium treatment, improve recovery effect, reduce production cost, and realize recovery and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

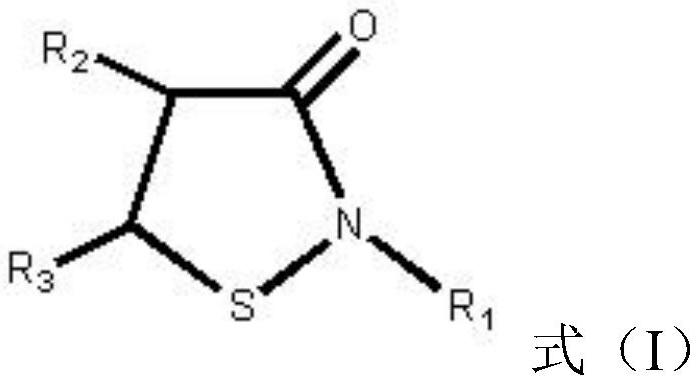

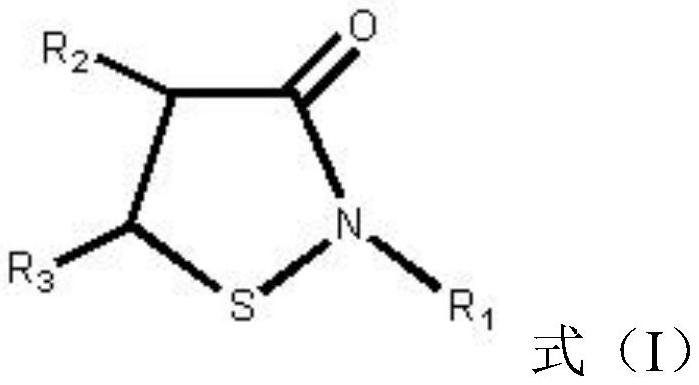

[0101] The preparation of triphenylphosphinecarbonyl rhodium acetylacetonate in the present invention can adopt following method to carry out: the rhodium trichloride that reclaims obtains and acetylacetone carry out the first reaction under the existence of solvent A, obtain acetylacetonate dihydroxy rhodium; Acetone dihydroxyrhodium and the recovered triphenylphosphine are subjected to a second reaction in the presence of solvent B to obtain triphenylphosphinecarbonyl rhodium acetylacetonate.

[0102] According to the present invention, in the first reaction, the recovered rhodium trichloride can be dissolved in solvent A, then mixed with acetylacetone, heated and reacted and then cooled to precipitate dihydroxyrhodium acetylacetonate crystals. The solvent A may be selected from N,N-dimethylformamide and / or N,N-dimethylacetamide, preferably N,N-dimethylformamide. The volume to mass ratio of solvent A to rhodium trichloride may be 30-100:1 mL / g, preferably 30-60: 1 mL / g, more...

Embodiment 1

[0112] 1) 1000g of acetylacetonate triphenylphosphine carbonyl rhodium acetylacetonate solution produced in the process of oxo alcohol (mainly butanol / octanol) is subjected to vacuum distillation, the temperature of the vacuum distillation is 120°C, and the pressure is -0.09MPa, The time was 4 hours, and 644 g of a rhodium-containing catalyst solution was obtained, wherein the concentration of rhodium was 300 ppm. After adding formaldehyde with a mass ratio of 1:1 to the rhodium-containing catalyst solution, a hydrochloric acid solution with a concentration of 10% by weight was added to adjust the pH of the formaldehyde and rhodium-containing catalyst solution to 3. The mixture was extracted at 120° C. for 1 h, and aqueous phase A and oil phase A were obtained by separation;

[0113] 2) Adjust the pH of the aqueous phase A to 9 with sodium carbonate, and filter to obtain a solid phase. Hydrochloric acid with a concentration of 10% by weight was added to the solid phase to adj...

Embodiment 2

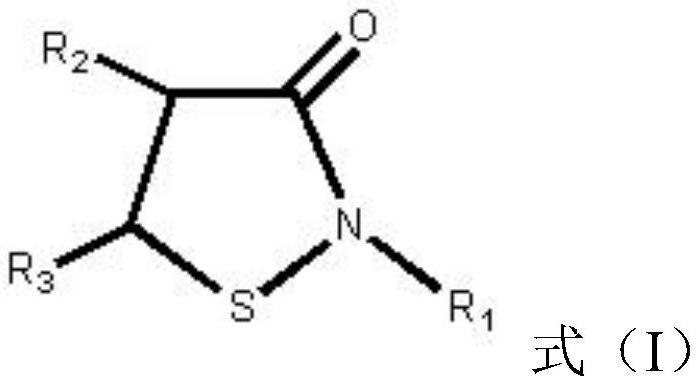

[0123] Carry out according to the method for embodiment 1, difference is, the mass ratio of the formaldehyde added in step 1) and rhodium-containing catalyst solution is 0.8:1; Step 2) in the mass ratio of methanol and solid phase is 2.4:1; Step 3 ) in the mass ratio of isothiazolinone and oil phase A is 0.4:1. As a result, the recovery rate of the obtained triphenylphosphine was 98.3%, the total recovery rate of rhodium was 99.7%, and the crystal yield of triphenylphosphinecarbonyl rhodium acetylacetonate was 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com