Modified alumina carrier as well as preparation method and application thereof

A technology of alumina carrier and modification, applied in catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve phase change, low crushing strength, single surface acidity and alkalinity etc. to achieve good strength, avoid acid cracking, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

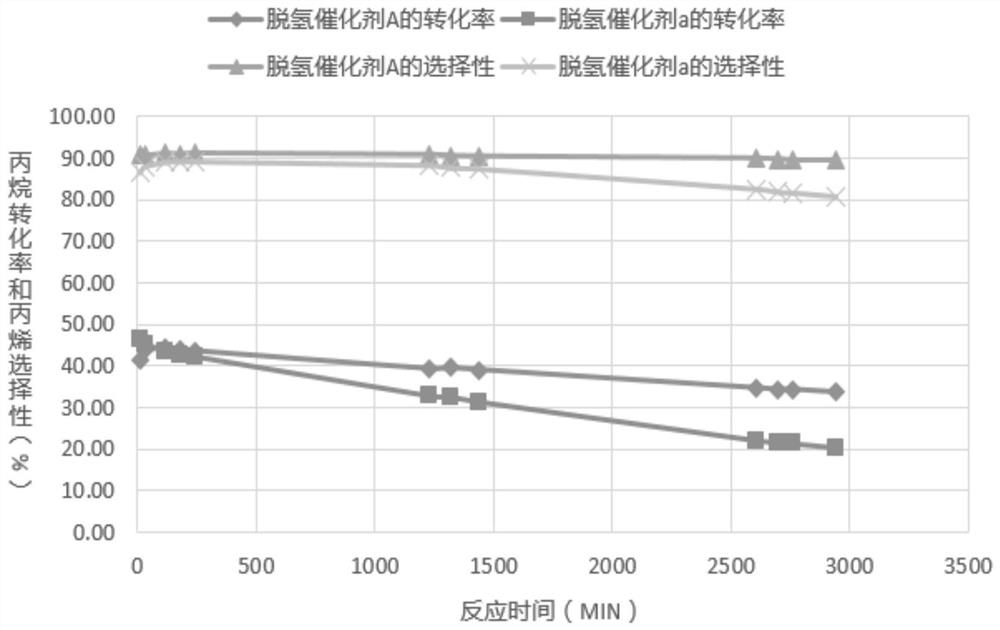

Examples

Embodiment 1

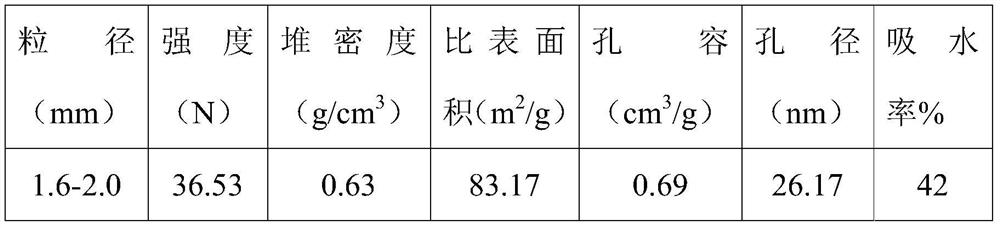

[0023] θ-Al 2 o 3 Preparation of vector

[0024] Firstly, 5 g of methylcellulose and 700 g of deionized water were mixed, stirred at room temperature for two hours, left to stand for 12 hours, and then 15 g of 3 mol / L nitric acid was added to obtain a kneaded gel. Add 120g of pseudo-boehmite powder, 5g of fennel powder, and 120g of kneading glue into the kneader, mix the above components evenly, and obtain powder after grinding, sieve with a 180-mesh sampling sieve, and sieve 45wt% of the The obtained powder is fed into the shaper to form a ball by rolling to make a cue ball. Then add the rest of the sieved powder to the shaping machine to make the cue ball shape and grow up, screen out the qualified balls with a diameter of 1.6-2.0mm, then dry the qualified balls at 110°C for 2 hours, and then bake them at 950°C Four hours, get θ-Al 2 o 3 Carrier; θ-Al 2 o 3 Carrier performance indicators are shown in Table 1.

[0025] θ-Al 2 o 3 carrier modification

[0026] Confi...

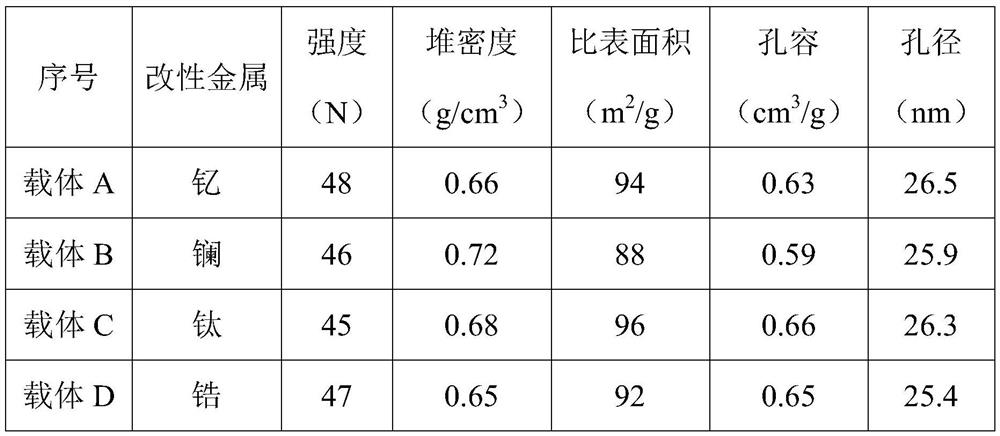

Embodiment 2

[0032] Modification of alumina

[0033] The θ-Al that makes in 30g embodiment 1 2 o 3 The carrier was mixed with 50 g of 5 mol / L lanthanum nitrate solution and then put into a reaction kettle. After hydrothermal reaction at 120° C. for 30 h, the sample was taken out and filtered. Put the filtered solid sample into an oven, dry it at 110°C for 8 hours, put the sample into a muffle furnace and bake it at 600°C for 5 hours to obtain the modified θ-Al 2 o 3 Carrier B. Modified θ-Al 2 o 3 The performance index of carrier B is shown in Table 2.

[0034] Preparation of dehydrogenation catalyst

[0035] 0.042g (NH 4 ) 2 PtCl6 , 0.05g SnCl 2 2H 2 O and 2.25g YCl 3 , 0.25g KCl was dissolved in 25g water to obtain an impregnation solution, and the impregnation solution was mixed with 10g modified θ-Al 2 o 3 Carrier B was mixed, put into a rotary evaporator, and stirred at room temperature under vacuum for 2 hours, then turned on the heating, and evaporated the solvent water...

Embodiment 3

[0039] Modification of alumina support

[0040] The θ-Al that makes in 25g embodiment 1 2 o 3 The carrier was mixed with 40 g of 5 mol / L ammonium titanyl oxalate solution, then put into a reaction kettle, subjected to hydrothermal reaction at 120° C. for 30 h, taken out, and filtered. The filtered sample was put into an oven and dried at 110°C for 8h. Put the dried sample into a muffle furnace, bake at 600°C for 5h, and take out the sample. Get modified θ-Al 2 o 3 Carrier C. Modified θ-Al 2 o 3 The performance index of carrier C is shown in Table 2.

[0041] Preparation of dehydrogenation catalyst

[0042] 0.042g (NH 4 ) 2 PtCl 6 , 0.05g SnCl 2 2H 2 O and 2.25g YCl 3 , 0.25g of KCl was dissolved in 5g of water to obtain an impregnation solution. Put the impregnation solution in a beaker, put 10g modified θ-Al 2 o 3 The carrier C is added into the impregnating liquid, and stirred evenly to obtain a solid product. After aging at room temperature for 5 hours, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com