Viscous raw material crushing equipment for new material preparation

A crushing equipment and new material technology, applied in the direction of grain processing, etc., can solve the problems of low crushing efficiency and crushing failure, and achieve the effect of full response and increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

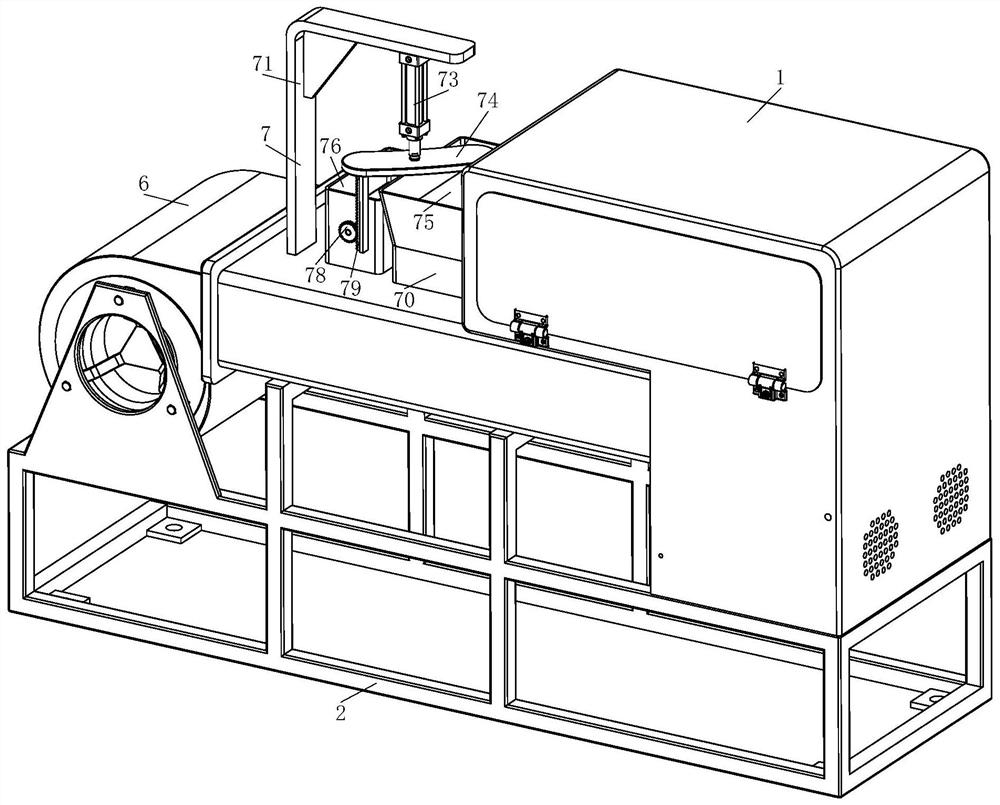

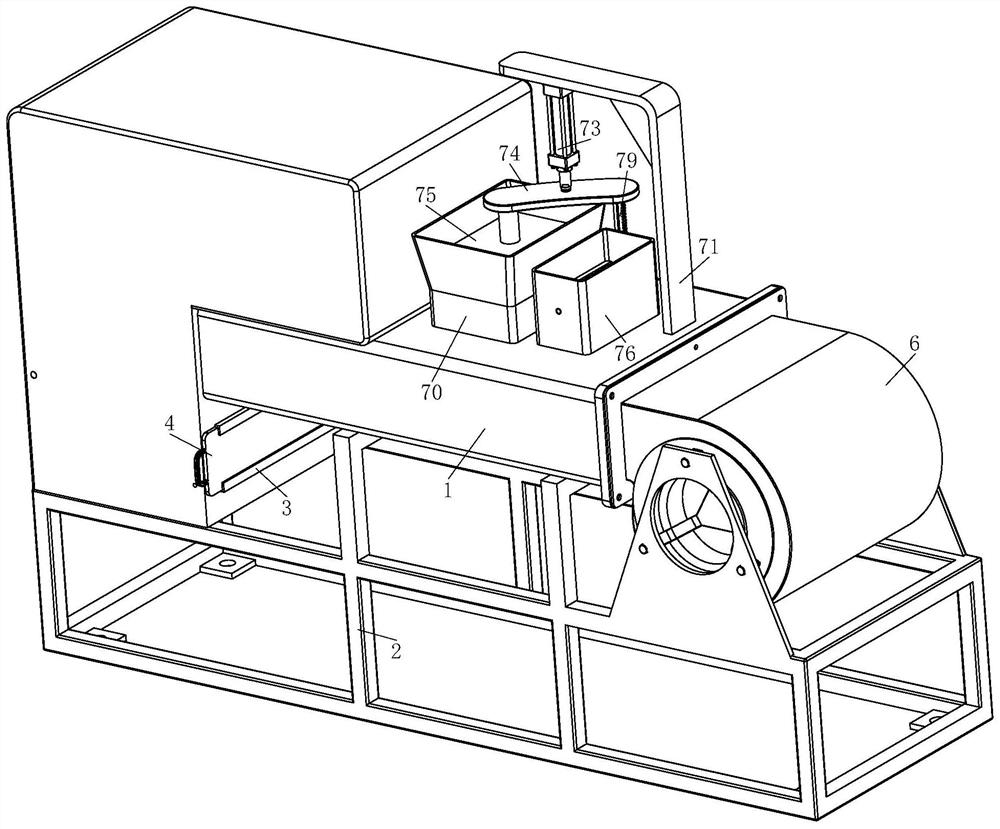

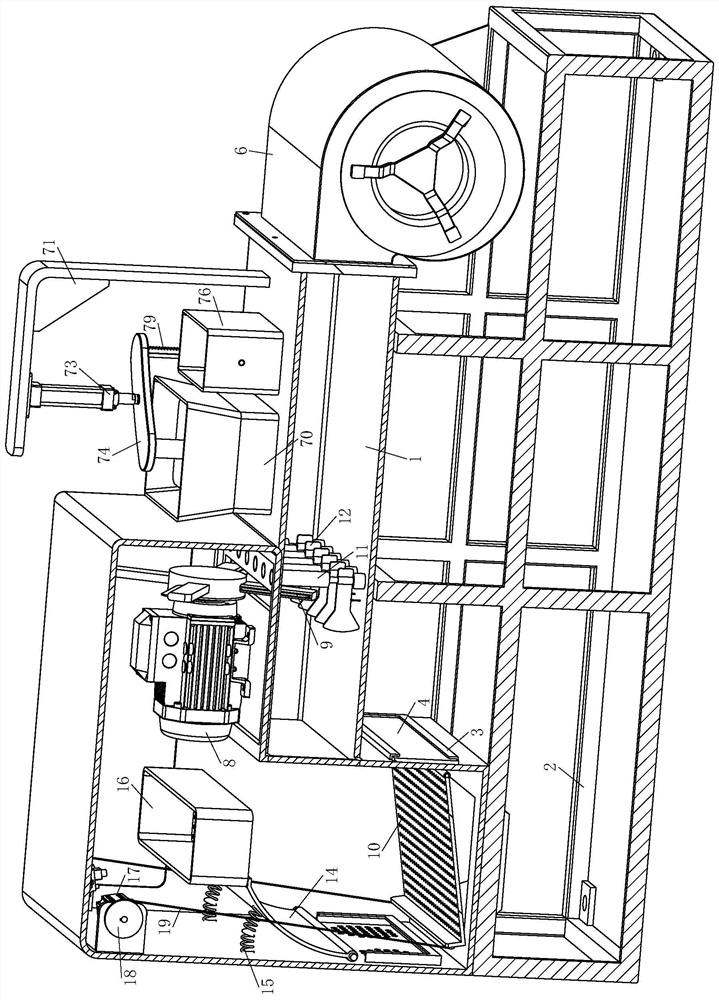

[0040] Such as Figures 1 to 10 As shown, a new material is prepared with a viscous raw material crushing apparatus, including the outer casing 1, the bottom frame 2, the carriage 3, and the upper portion of the chassis 2, and the outer casing 1 and the chassis. 2 Secure connections; one side of the outer casing 1 is provided with a discharge port 5; the carriage 3 is provided on one side of the housing opening 5; the carriage 3 is fixedly coupled to the outer casing 1; A slot is provided on one side of the carriage 3; the inside of the chute is disposed in the inside of the slide; the shutter 4 is slidable with the chute; further includes a fan 6, a feed device 7, a motor 8, cutter 9 and discharge plate 10; the upper portion of the chassis 2 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap