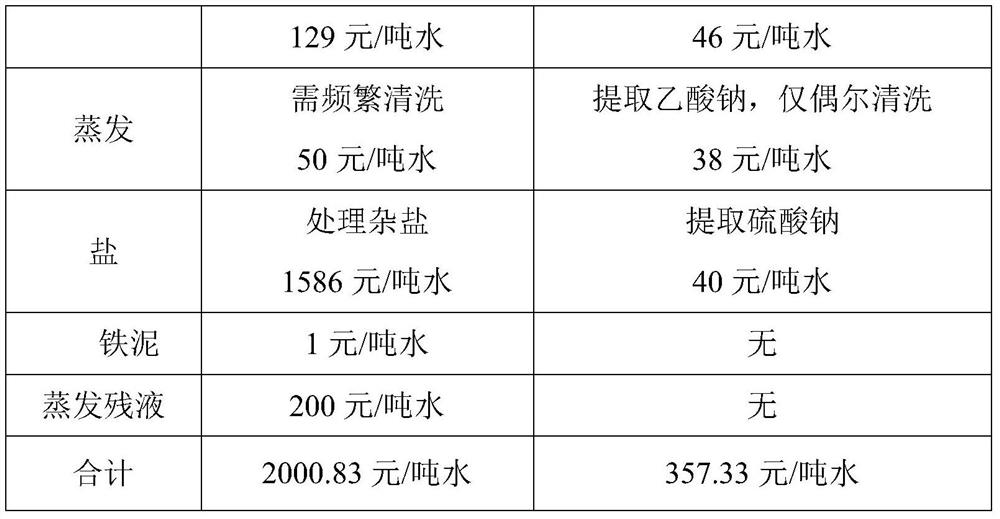

Process for treating disperse dye production wastewater and recycling salt resources

A technology for producing wastewater and disperse dyes, which is applied in biological water/sewage treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of difficult actual operation, high operating cost, long treatment route, etc., and achieve high solvent quality. High, good chroma and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

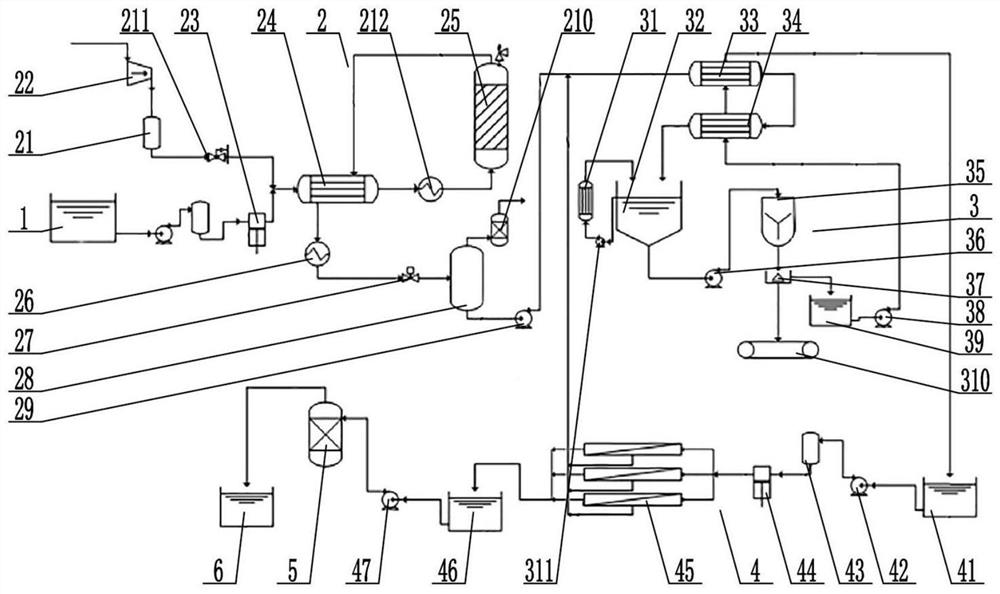

[0053] A process for the treatment of disperse dye production wastewater and salinity resource recovery. The disperse dye production wastewater undergoes neutralization treatment, ECO subcritical water catalytic oxidation, gas-liquid separation, freeze crystallization, nanofiltration membrane concentration and separation, and biochemical treatment to achieve Emission standards, and recovery of salt and solvent, the specific steps are as follows:

[0054] Q1: Neutralization treatment: pass the disperse dye production wastewater into the wastewater pretreatment device 1, and then add sodium hydroxide to adjust the pH value of the disperse dye production wastewater to weakly acidic 5.5. At this time, the sulfuric acid in the disperse dye production wastewater passes through Sodium sulfate is generated after the reaction;

[0055] Q2: ECO subcritical water catalytic oxidation: the disperse dye production wastewater after neutralization treatment enters the ECO subcritical water ca...

Embodiment 2

[0070] A process for the treatment of disperse dye production wastewater and salinity resource recovery. The disperse dye production wastewater undergoes neutralization treatment, ECO subcritical water catalytic oxidation, gas-liquid separation, freeze crystallization, nanofiltration membrane concentration and separation, and biochemical treatment to achieve Emission standards, and recovery of salt and solvent, the specific steps are as follows:

[0071] Q1: Neutralization treatment: Pass the disperse dye production wastewater into the wastewater pretreatment device 1, and then add sodium carbonate to adjust the pH value of the disperse dye production wastewater to weakly acidic 6. At this time, the sulfuric acid in the disperse dye production wastewater is reacted After that, sodium sulfate is generated;

[0072] Q2: ECO subcritical water catalytic oxidation: the disperse dye production wastewater after neutralization treatment enters the ECO subcritical water catalytic oxida...

Embodiment 3

[0087] A process for the treatment of disperse dye production wastewater and salinity resource recovery. The disperse dye production wastewater undergoes neutralization treatment, ECO subcritical water catalytic oxidation, gas-liquid separation, freeze crystallization, nanofiltration membrane concentration and separation, and biochemical treatment to achieve Emission standards, and recovery of salt and solvent, the specific steps are as follows:

[0088] Q1: Neutralization treatment: Pass the disperse dye production wastewater into the wastewater pretreatment device 1, and then add sodium carbonate or sodium hydroxide to adjust the pH value of the disperse dye production wastewater to weakly acidic 6.5. At this time, the disperse dye production wastewater The sulfuric acid reacts to generate sodium sulfate;

[0089] Q2: ECO subcritical water catalytic oxidation: the disperse dye production wastewater after neutralization treatment enters the ECO subcritical water catalytic oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com