Furfuryl alcohol modification liquid, preparation method and application thereof

A modified liquid, furfuryl alcohol technology, applied in the direction of manufacturing tools, wood treatment, pressure impregnation, etc., can solve the problems of high wood weight gain, restricted development, violent catalyst reaction, etc., and achieve excellent flame retardant and smoke suppression performance and corrosion resistance. properties, improved dimensional stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0049] Example 1

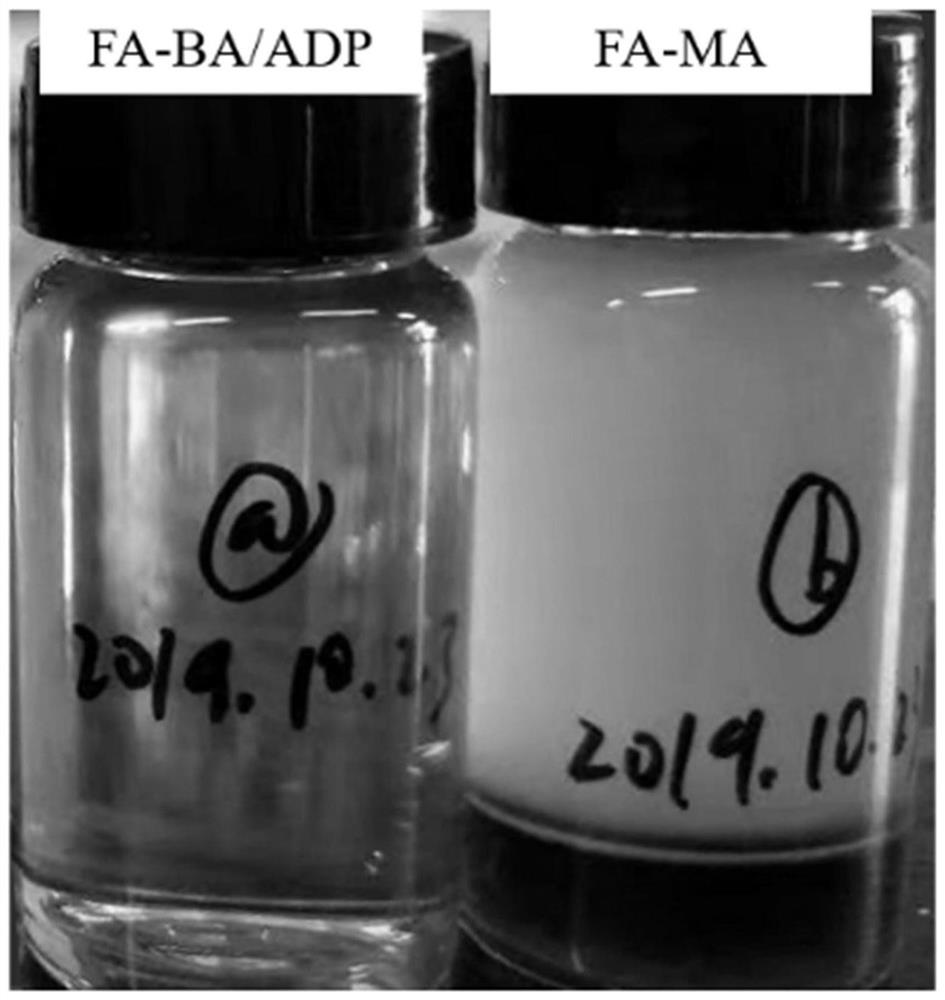

[0050] Put 810mL of distilled water into a 2L glass beaker and preheat it to 35°C, then slowly add 32g of boron phosphate and 8g of phytic acid in sequence, stir with a magnetic stirrer for 10min until all the solids are dissolved, and obtain a clear, transparent and homogeneous solution, which is to be mixed After the solution was cooled to room temperature, 150 g of furfuryl alcohol was slowly added, and the mixture was magnetically stirred for 10 min to obtain a furfuryl alcohol modified solution.

[0051] The furfuryl alcohol modified liquid prepared above was used to prepare the standard specimen of the furfuryl alcohol resin-modified wood of Example 1.

Example Embodiment

[0052] Example 2

[0053] Put 818mL of distilled water into a 2L glass beaker and preheat it to 35°C, then slowly add 24g of boron phosphate and 8g of ammonium dihydrogen phosphate, stir with a magnetic stirrer for 10min until all the solids are dissolved, and obtain a clear, transparent and homogeneous solution, After the mixed solution was cooled to room temperature, 150 g of furfuryl alcohol was slowly added, and the mixture was magnetically stirred for 10 min to obtain a furfuryl alcohol modified solution.

[0054] The furfuryl alcohol modified liquid prepared above was used to prepare the standard specimen of the furfuryl alcohol resin-modified wood of Example 2.

Example Embodiment

[0055] Example 3

[0056] Put 810mL of distilled water into a 2L glass beaker and preheat to 35°C, then slowly add 32g of zinc borate and 8g of phytic acid in turn, stir with a magnetic stirrer for 10min until all solids are dissolved, and obtain a clear, transparent and homogeneous solution, which is to be mixed After the solution was cooled to room temperature, 150 g of furfuryl alcohol was slowly added, and the mixture was magnetically stirred for 10 min to obtain a furfuryl alcohol modified solution.

[0057] The furfuryl alcohol modified liquid prepared above was used to prepare the standard specimen of the furfuryl alcohol resin-modified wood of Example 3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap