A kind of cheese stick and its production technology

A cheese, cross-linking modification technology, applied in the field of cheese sticks and its production technology, can solve problems such as cheese stick breakage, achieve the effect of improving low-temperature toughness and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

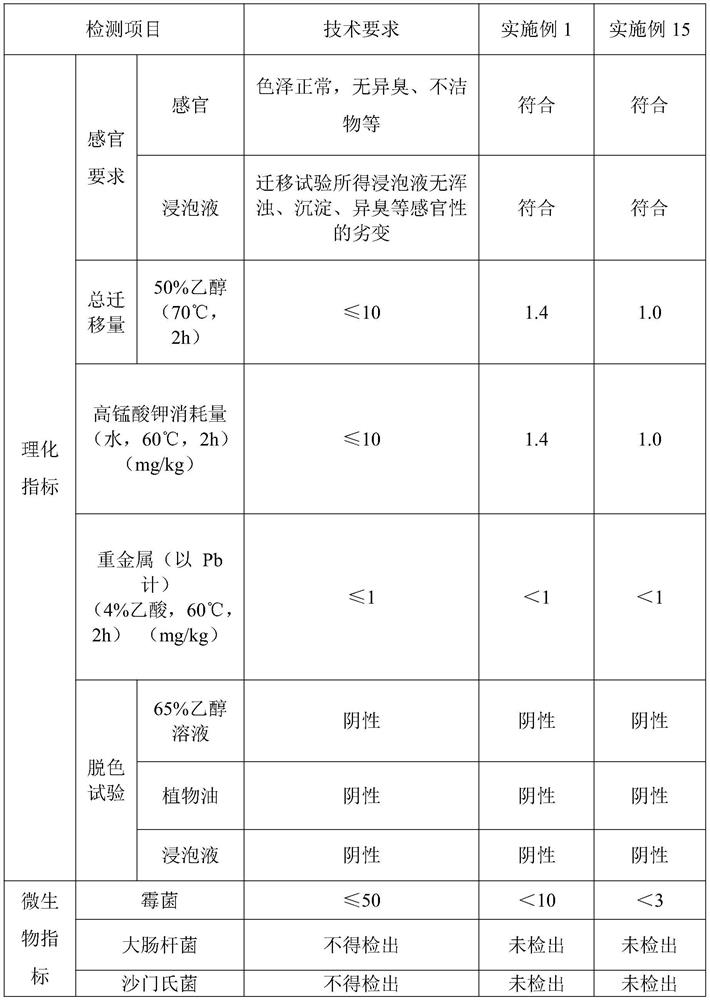

Examples

preparation example 1

[0046] The preparation of cross-linked modified carbon nanotubes specifically includes the following steps:

[0047] S11, the preparation of acid-treated modified multi-walled carbon nanotubes, after immersing 0.3kg multi-walled carbon nanotubes in 2L of mixed acid solution at 25°C for 6h, ultrasonically dispersed at 55°C at a frequency of 40kHz for 24h, and the ultrasonically dispersed The multi-walled carbon nanotubes were cooled at 25°C for 1 hour and then centrifuged to remove the mixed acid solution. The centrifuged multi-walled carbon nanotubes were washed 4 times with distilled water, and the washed multi-walled carbon nanotubes were placed in a vacuum drying oven at 40 After drying at ℃ for 2 hours, acid-treated modified multi-walled carbon nanotubes were prepared, wherein the mixed acid solution was prepared by mixing concentrated sulfuric acid with a mass concentration of 98% and concentrated nitric acid with a mass concentration of 50% in a volume ratio of 3:1. beco...

preparation example 2

[0051] The preparation of cross-linked modified carbon nanotubes specifically includes the following steps:

[0052] S11, the preparation of acid-treated modified multi-walled carbon nanotubes, after immersing 0.3kg multi-walled carbon nanotubes in 2L of mixed acid solution at 25°C for 6h, ultrasonically dispersed at 55°C at a frequency of 40kHz for 24h, and the ultrasonically dispersed The multi-walled carbon nanotubes were cooled at 25°C for 1 hour and then centrifuged to remove the mixed acid solution. The centrifuged multi-walled carbon nanotubes were washed 4 times with distilled water, and the washed multi-walled carbon nanotubes were placed in a vacuum drying oven at 40 After drying at ℃ for 2 hours, acid-treated modified multi-walled carbon nanotubes were prepared, wherein the mixed acid solution was prepared by mixing concentrated sulfuric acid with a mass concentration of 98% and concentrated nitric acid with a mass concentration of 50% in a volume ratio of 3:1. beco...

preparation example 3

[0056] The preparation of cross-linked modified carbon nanotubes specifically includes the following steps:

[0057] S11, preparation of modified multi-walled carbon nanotubes by acid treatment, immerse 0.3kg multi-walled carbon nanotubes in 2L of concentrated nitric acid solution with a mass concentration of 50% at 25°C for 6h, and then ultrasonically disperse at 55°C at a frequency of 40kHz After 24 hours, the multi-walled carbon nanotubes after ultrasonic dispersion were cooled at 25°C for 1 hour, then centrifuged to remove the mixed acid solution, and the centrifuged multi-walled carbon nanotubes were washed 4 times with distilled water, and the washed multi-walled carbon nanotubes were After drying in a vacuum oven at 40°C for 2 hours, the acid-treated modified multi-walled carbon nanotubes were prepared;

[0058] S12, preparing treatment liquid A, adding 0.6 kg of polyether-modified polydimethylsiloxane to ethanol aqueous solution A and mixing and stirring for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com