Landfill leachate concentrated liquor and lime slurry synergistic semi-dry desulfurization process and system thereof

A technology for desulfurization of landfill leachate and semi-dry method, which is applied in the field of semi-dry desulfurization process and system of landfill leachate concentrate and lime slurry, which can solve the problem of incomplete treatment of harmful components in leachate and concentrate Large size, many processing equipment and other problems, to achieve the effect of reducing water resource consumption, less equipment and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

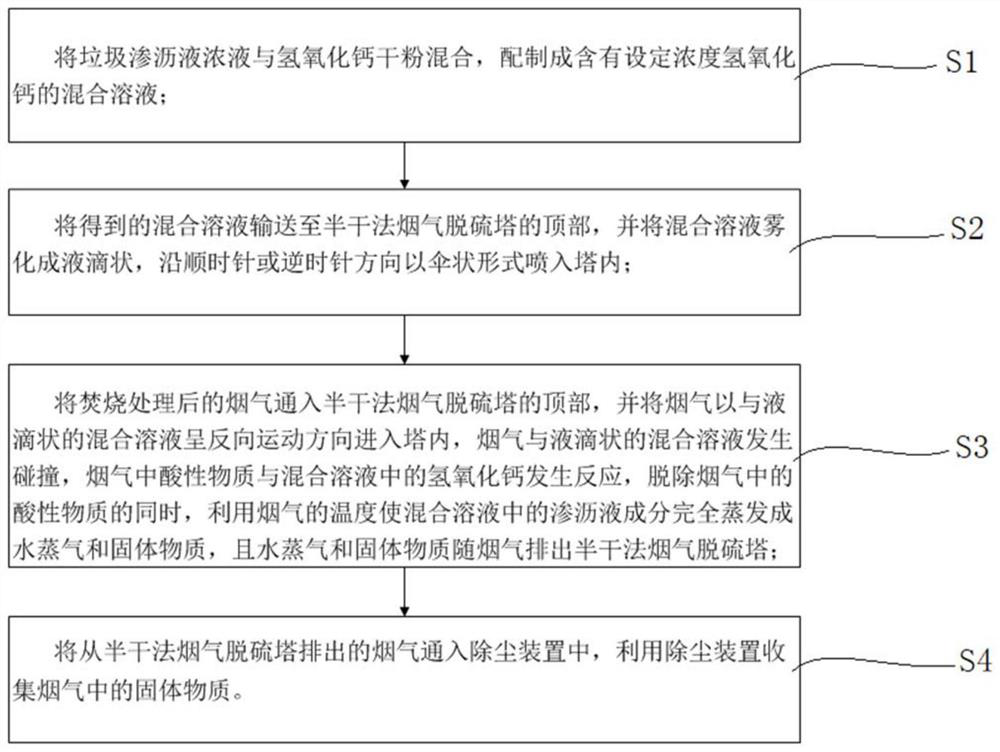

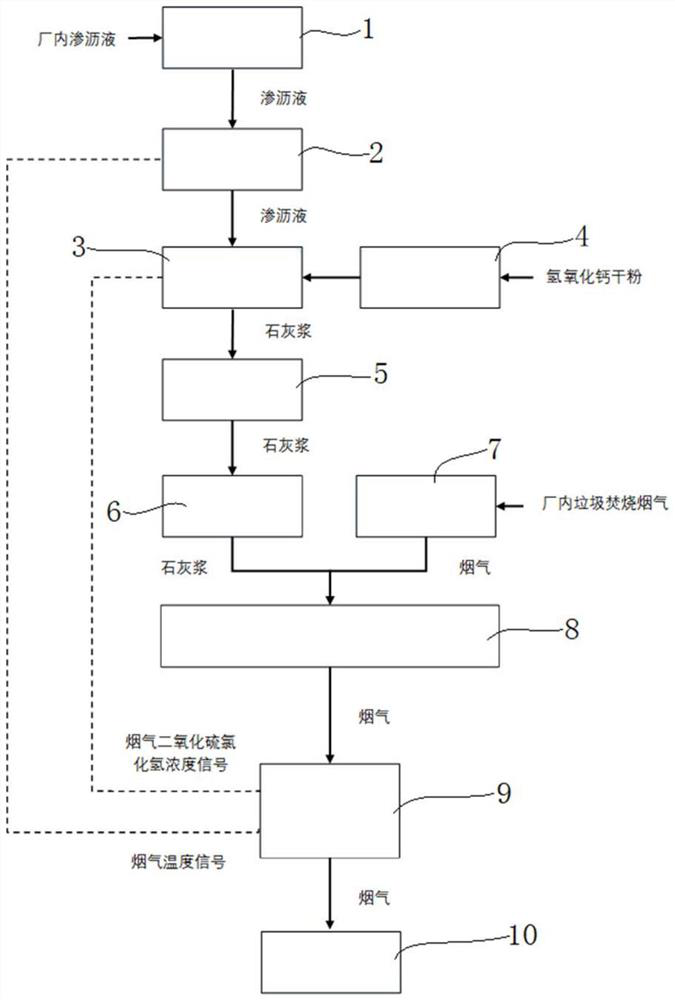

[0033] figure 1 为本发明一优选实施例的一种垃圾渗沥液浓液与石灰浆协同半干法脱硫工艺的流程图。 refer to figure 1 所示,本实施例包括:

[0034] S1:将垃圾渗沥液浓液与氢氧化钙干粉按照一定的比例混合,配制成浓度为7%-13%的石灰浆混合溶液。本步骤中的垃圾渗沥液浓液是针对垃圾焚烧厂内的渗沥液进行处理,将垃圾焚烧厂内收集的渗沥液储存到用于盛放液体的装置内,储存渗沥液的装置的容积满足厂内3天-5天的渗沥液收集量。配制完成的石灰浆是由渗沥液,氢氧化钙溶液组成的混合溶液。

[0035] S2:将S1配制的石灰浆输送至半干法烟气脱硫塔8的顶部,并将石灰浆雾化成液滴状,使得液滴比表面积最大、石灰浆可以在最短时间内最大程度地与烟气中的酸性物质进行有效中和反应,从而达到脱除酸性物质的作用,石灰浆液沿顺时针或逆时针方向以伞状形式喷入塔内。

[0036] S3:将焚烧处理后的烟气通入半干法烟气脱硫塔8的顶部,并将烟气以与液滴状的石灰浆呈反向运动方向进入塔内,例如,当将石灰浆雾化后的液滴沿顺时针方向喷入塔内时,则将烟气以逆时针方向通入塔内;当将石灰浆雾化...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com