A degradable double-layer polysaccharide active film and its preparation method

A polysaccharide and active technology, applied in the field of degradable double-layer polysaccharide active film, can solve the problems of poor barrier properties, weak mechanical properties, and insignificant bacteriostatic and fresh-keeping effects, and achieve the effect of enhancing bacteriostatic effect and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

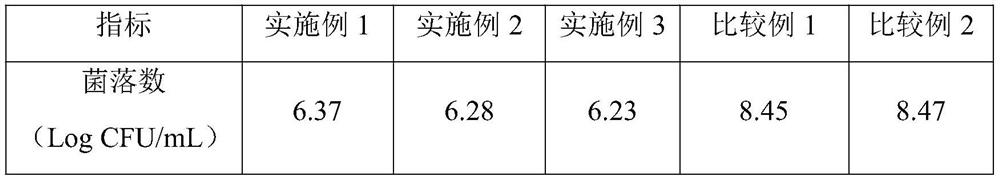

Examples

Embodiment 1

[0039] (1) Preparation of dihydromyricetin / hydroxypropyl-β-cyclodextrin inclusion compound: 3.08 g of hydroxypropyl-β-cyclodextrin was dissolved in 200 mL of pure water, and stirred continuously at 45°C. Dissolve 0.64g of dihydromyricetin in 3mL of ethanol, and slowly add the above-mentioned hydroxypropyl-β-cyclodextrin solution, continue to stir and react for 6h, and obtain dihydromyricetin / hydroxypropyl-β-cyclodextrin after freeze-drying Fine clathrate.

[0040] (2) Preparation of film-forming solution: Add 4 g of sodium alginate to 200 mL of pure water, stir in a water bath at 60°C for 4 h, add 2 g of glycerin, continue stirring for 2 h, then add 0.4 g of dihydromyricetin / hydroxypropyl-β-cyclo Dextrin inclusion compound, continue stirring for 20 minutes to obtain sodium alginate-dihydromyricetin / hydroxypropyl-β-cyclodextrin inclusion compound film-forming solution I. Add 4g of chitosan to 200mL of 1% (v / v) acetic acid aqueous solution, stir in a water bath at 60°C for 4h, ...

Embodiment 2

[0043] (1) Preparation of dihydromyricetin / hydroxypropyl-β-cyclodextrin inclusion complex: 1.54 g of hydroxypropyl-β-cyclodextrin was dissolved in 100 mL of pure water, and stirred continuously at 50°C. Dissolve 0.32g of dihydromyricetin in 1mL of ethanol, and slowly add the above-mentioned hydroxypropyl-β-cyclodextrin solution, continue to stir and react for 4h, and obtain dihydromyricetin / hydroxypropyl-β-cyclodextrin after freeze-drying Fine clathrate.

[0044] (2) Preparation of film-forming solution: Add 2 g of sodium alginate to 100 mL of pure water, stir in a water bath at 55°C for 3 h, add 1 g of glycerin, continue stirring for 1 h, then add 0.1 g of dihydromyricetin / hydroxypropyl-β-cyclo For dextrin inclusion compound, continue to stir for 10 minutes to obtain sodium alginate-dihydromyricetin / hydroxypropyl-β-cyclodextrin inclusion compound film-forming solution I. Add 2g of chitosan to 100mL of 1% (v / v) acetic acid aqueous solution, stir in a water bath at 55°C for 3h...

Embodiment 3

[0047] (1) Preparation of dihydromyricetin / hydroxypropyl-β-cyclodextrin inclusion compound: 2.31 g of hydroxypropyl-β-cyclodextrin was dissolved in 150 mL of pure water, and stirred continuously at 45°C. Dissolve 0.43g of dihydromyricetin in 2mL of ethanol, and slowly add the above-mentioned hydroxypropyl-β-cyclodextrin solution, continue to stir and react for 8h, and obtain dihydromyricetin / hydroxypropyl-β-cyclodextrin after freeze-drying Fine clathrate.

[0048] (2) Preparation of film-forming solution: add 3g of sodium alginate to 150mL of pure water, stir in a water bath at 60°C for 2h, add 1.5g of glycerin, continue stirring for 1.5h, then add 0.45g of dihydromyricetin / hydroxypropyl-β -Cyclodextrin inclusion compound, continue to stir for 30 minutes to obtain sodium alginate-dihydromyricetin / hydroxypropyl-β-cyclodextrin inclusion compound film-forming solution I. Add 3g of chitosan to 150mL of 1% (v / v) acetic acid aqueous solution, stir in a water bath at 60°C for 2h, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com