Manufacture of reinforced shell part of wind turbine blade

A technology for wind turbines and shells, applied in the field of manufacturing reinforced shell components, which can solve the problems of reducing the stiffness and strength of wind turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In the following graphical description, the same reference numerals denote the same elements, and thus may not be described without all diagrams.

[0070] figure 1 A conventional modern counteractive wind turbine 2 is shown in accordance with the so-called "Danish Concept" has a tower 4, a nip 6, and a rotor having a substantially horizontal rotor shaft. The rotor includes a hub 8 and three blades 10 extend radially radially from the hub 8, each blade having the blade root portion 16 closest to the hub and the left portion 14 of the movable portion 8.

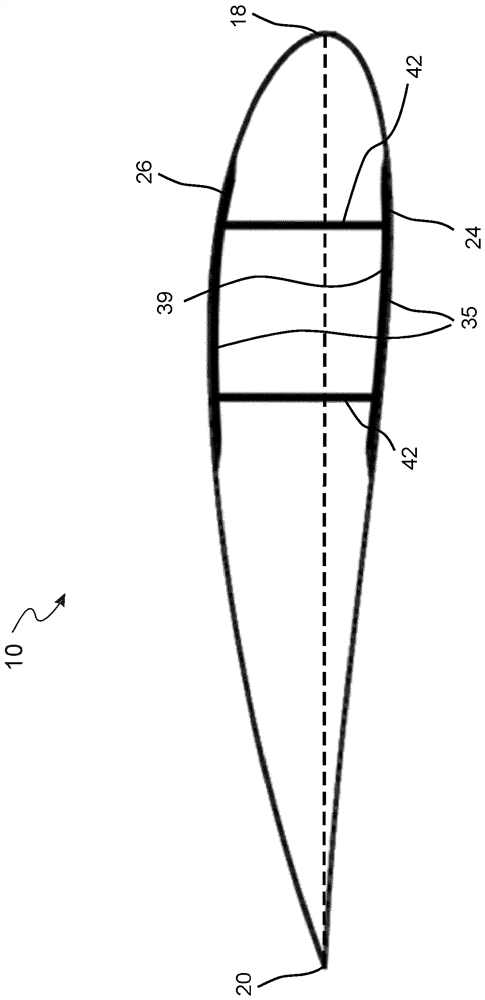

[0071] figure 2 A schematic diagram of an exemplary wind turbine blade 10 is shown. The wind turbine blade 10 has a shape with a conventional wind turbine blade with a rheal end and a tip end, and includes the root region 30 closest to the hub, the molding or airfoil region 34, which is farther away from the hub, and at the root The transition zone 32 between the region 30 and the airfoil region 34. The blade 10 includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com