Copper nanowire material, manufacturing method thereof and application thereof

A copper nanowire, divalent copper technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of high overpotential, achieve promotion, promote catalytic performance, and reduce preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0036] Example 1

[0037] Embodiments of the present application provides a copper nanowire material, particularly a method comprising:

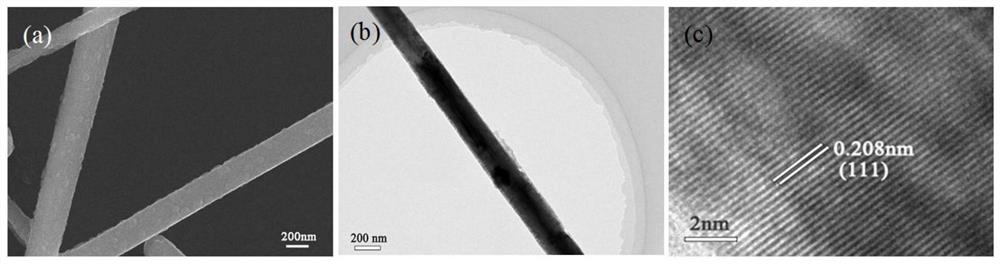

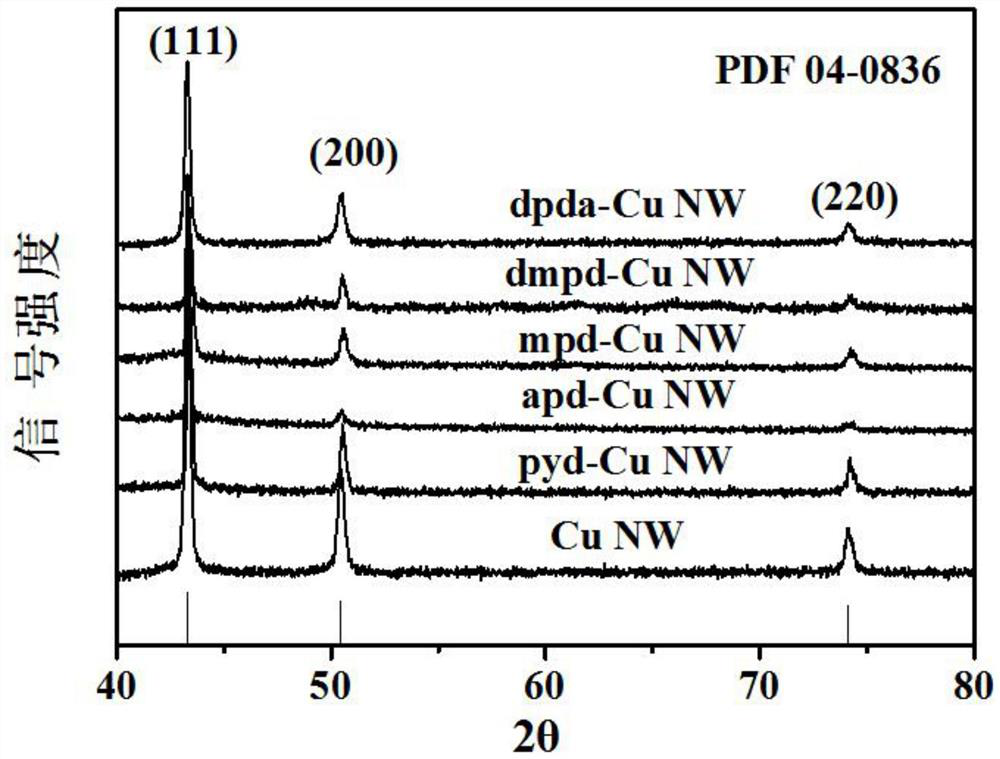

[0038] 60g of sodium hydroxide was dissolved in 100mL of water, 0.12g of Cu (NO 3 ) 2 · 3h 2 O was dissolved in 20mL water, and mixing the two aqueous solutions to 150mL round bottom flask, a uniformly mixed, and then added a solution of 1.5mL ethylenediamine, mixed, heated to an oil bath of 70 ℃, speed of at 200 rpm, after five minutes incubation, was added 0.5mL mass fraction of 35% hydrazine hydrate, holding the speed, reaction 0.5h, floating above a layer of red substance solution, the upper layer material by centrifugation 8000rpm and washed with ethanol and water, respectively, washed 3 times, then the resultant copper nanowires immersed in 0.5M HCl for 12h, washed with ethanol and then by water, and then dispersed in ethanol to obtain a solution of copper nanowires, nanowires obtain a copper (Cu NW) and dried .

[0039] Take the copper na...

Example Embodiment

[0041] Example 2

[0042] Embodiments of the present application provides a copper nanowire material, particularly a method comprising:

[0043] 60g of sodium hydroxide was dissolved in 100mL of water, 0.12g of Cu (NO 3 ) 2 · 3h 2O dissolve in 20 ml of water, mix the above two aqueous solutions into a 150 mL round bottom flask, and then mixed well, then add 1.5 ml of an anediamine solution, mix evenly, and heated to 70 ° C in the oil bath pan, and the rotational speed is After 200RPM, after 5 minutes, 0.5 ml of mass fraction was 35% hydrated hydrate, retained speed, and after 0.5 h, the solution floated with a layer of red substance, and centrifuged the upper substance by 8000 rpm, ethanol and water Wash 3 times, then the resulting copper nanowire was soaked in a 0.5 m HCl for 12 h, then washed by ethanol and water, then dispersed into ethanol to give a copper nanowire solution, dried to obtain a copper nanowire (Cu NW) .

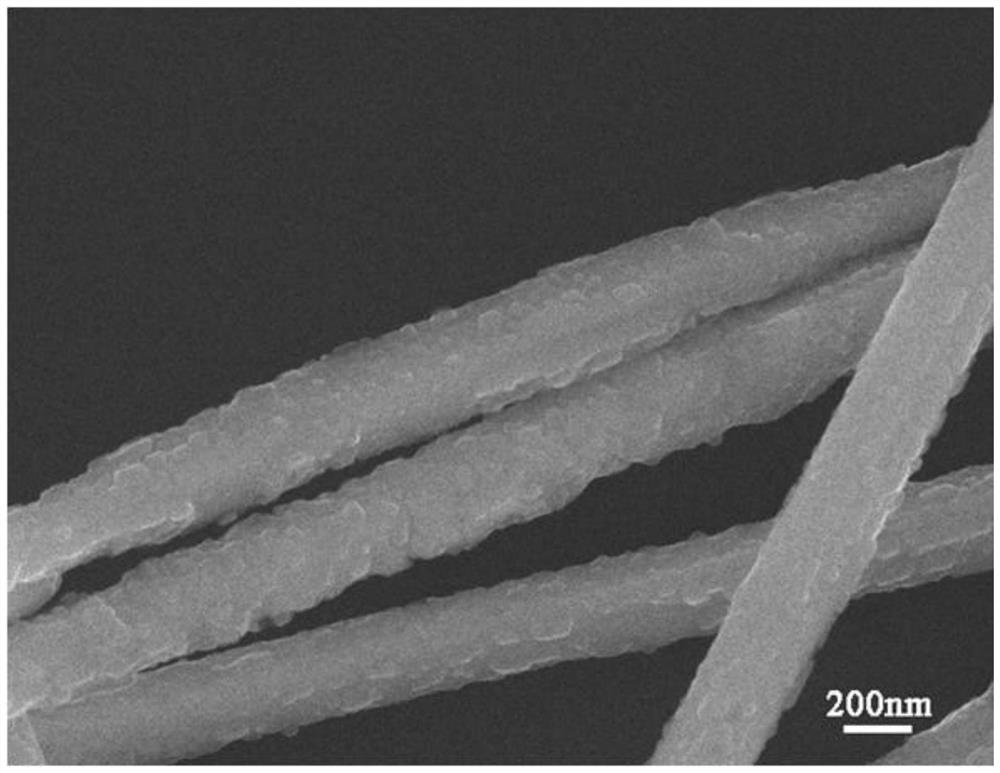

[0044] The above-described 20 mg copper nanowire was disp...

Example Embodiment

[0046] Example 3

[0047] The present application example provides a copper nanowire material, and the specific method includes:

[0048] 60 g of sodium hydroxide was dissolved in 100 ml of water, 0.12 g of Cu (NO 3 ) 2 · 3h 2 O dissolve in 20 ml of water, mix the above two aqueous solutions into a 150 mL round bottom flask, and then mixed well, then add 1.5 ml of an anediamine solution, mix evenly, and heated to 70 ° C in the oil bath pan, and the rotational speed is After 200RPM, after 5 minutes, 0.5 ml of mass fraction was 35% hydrated hydrate, retained speed, and after 0.5 h, the solution floated with a layer of red substance, and centrifuged the upper substance by 8000 rpm, ethanol and water Wash 3 times, then the resulting copper nanowire was soaked in a 0.5 m HCl for 12 h, then washed by ethanol and water, then dispersed into ethanol to give a copper nanowire solution, dried to obtain a copper nanowire (Cu NW) .

[0049] Take the above-described 20 mg of copper nanowires to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap