Silver film composite cloth with honeycomb heat storage structure, and preparation method thereof

A technology of honeycomb and silver film, applied in the field of fabrics, can solve the problems of heavy wearing, poor air permeability, and poor thermal insulation of ultra-thin down jackets, and achieve the effects of improving antibacterial ability, enhancing heat storage capacity, and improving cold resistance and heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

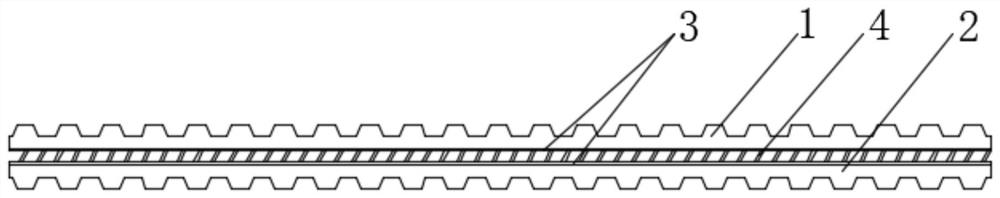

[0028] like figure 1 As shown, a silver film composite cloth with a honeycomb heat storage structure comprises a honeycomb surface layer 1, a honeycomb inner layer 2, a silver film layer 3 arranged on the opposite surface of the honeycomb surface layer 1 and the honeycomb inner layer 2, bonded to the The honeycomb glue net 4 arranged obliquely between the honeycomb surface layer 1 and the honeycomb inner layer 2. in,

[0029] The side surfaces of the honeycomb surface layer 1 and the honeycomb inner layer 2 away from each other are honeycomb surfaces, and the surfaces of the side close to each other are planes. The honeycomb surface layer 1 and the honeycomb inner layer 2 are made of corn bio-based fiber, hollow Made of polyester fiber, Xw-ele conductive fiber textile.

[0030] The honeycomb rubber net 4 includes spandex elastic fiber, bamboo fiber, molybdenum trioxide nano powder, nano silver antibacterial particles, polymer latex, and the spandex elastic fiber, bamboo fibe...

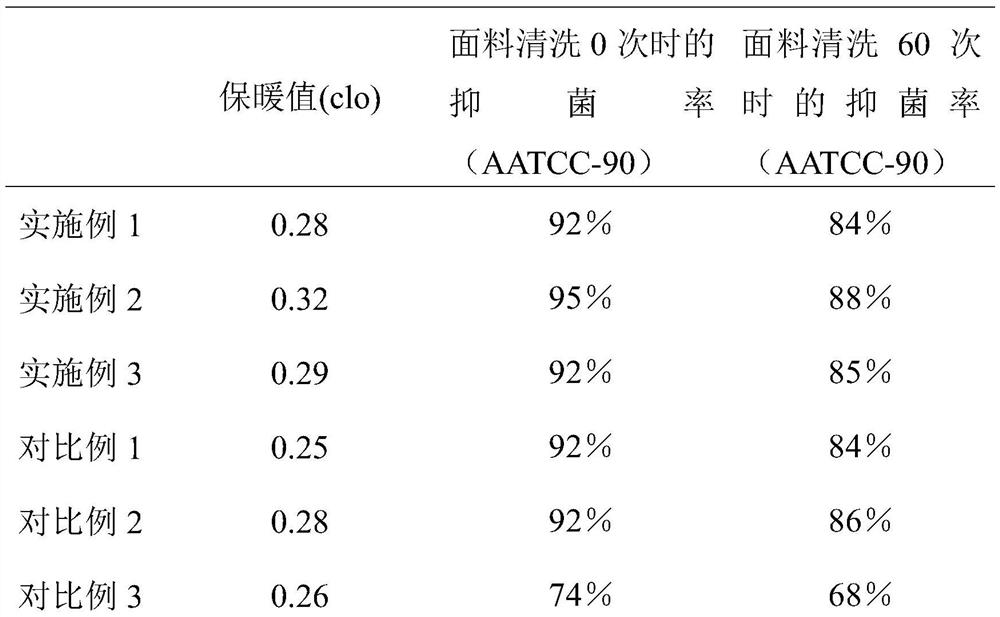

Embodiment 2

[0038] This embodiment provides a silver-film composite fabric with a honeycomb heat storage structure and its preparation method. The silver-film composite fabric and its preparation steps are basically the same as in Example 1, the only difference being: the spandex elastic fiber, bamboo fiber, The mass ratio of molybdenum trioxide nano-powder, nano-silver antibacterial particles, and polymer latex is 0.75:0.25:0.15:0.15:8.7; the spray thickness of the mixed glue sprayed on the honeycomb surface is 0.8mm, and the honeycomb surface layer 1 is obliquely upward The vertical height of the stretch is 0.5 mm.

Embodiment 3

[0040] This embodiment provides a silver-film composite fabric with a honeycomb heat storage structure and its preparation method. The silver-film composite fabric and its preparation steps are basically the same as in Example 1, the only difference being: the spandex elastic fiber, bamboo fiber, The mass ratio of molybdenum trioxide nano-powder, nano-silver antibacterial particles, and polymer latex is 1:0.2:0.2:0.1:8.5; the thickness of the mixed glue sprayed on the honeycomb surface is 1mm, and the honeycomb surface layer 1 is pulled up obliquely The vertical height of the extension is 1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com