Nuclear rare earth modified aluminum-based boron carbide material and preparation method thereof

A technology of aluminum-based boron carbide and rare earth modification, which is applied in the field of rare earth modified aluminum-based boron carbide materials for nuclear use and its preparation, can solve problems such as difficult batch production, difficult plastic processing, and poor corrosion resistance, so as to achieve high efficiency. Density, increased plasticity and ductility, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

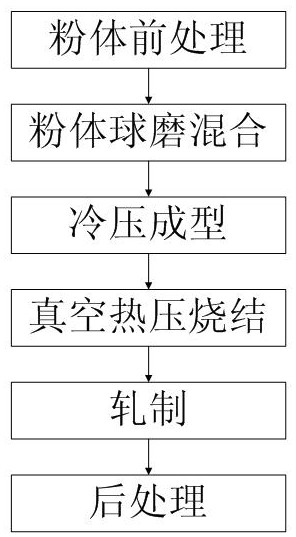

[0031] like figure 1 Shown, the preparation method of rare earth modified aluminum-based boron carbide material comprises the following steps:

[0032] (1) Powder pretreatment, pre-oxidize the 6061 aluminum alloy powder in an oxygen-containing atmosphere, the treatment temperature is 240°C-270°C, preferably 250°C-260°C;

[0033] (2) Powder ball milling and mixing, the pre-oxidized powder obtained in step (1) and boron carbide powder, rare earth oxide powder are fully ball milled and mixed in a polyurethane ball milling tank, the ball milling time is 12-24 hours, and the polyurethane ball milling tank The milling balls are boron carbide balls;

[0034] (3) Cold press forming, cold press forming the mixed powder obtained in step (2), the cold press forming pressure is 60MPa-80MPa, preferably 65MPa-75MPa;

[0035] (4) Vacuum hot-pressing sintering, using a vacuum hot-pressing furnace to hot-press the cold-pressed blank obtained in step (3) to obtain a hot-pressed billet. The ho...

Example Embodiment

[0038] Embodiment one

[0039] Rare earth modified aluminum-based boron carbide material, the weight ratio of raw material components is:

[0040] components parts by weight Boron carbide powder (particle size 15 microns) 14 Boron carbide powder (particle size 1 micron) 14 Rare earth oxide powder (gadolinium oxide, particle size 10 microns) 1 Rare earth oxide powder (samarium oxide, particle size 10 microns) 1 6061 aluminum alloy powder (particle size 45 microns) 70

[0041] The preparation method of a rare earth modified aluminum-based boron carbide material comprises the following steps:

[0042] (1) Powder pre-treatment, the 6061 aluminum alloy powder is subjected to pre-oxidation treatment in an oxygen-containing atmosphere, and the treatment temperature is 250°C;

[0043] (2) Powder ball milling, the pre-oxidized powder obtained in step (1), boron carbide powder, and rare earth oxide powder are fully ball milled and mixed in ...

Example Embodiment

[0049] Embodiment two

[0050] Rare earth modified aluminum-based boron carbide material, the weight ratio of raw material components is:

[0051] components parts by weight Boron carbide powder (particle size 3 microns) 20 Rare earth oxide powder (gadolinium oxide, particle size 10 microns) 2 6061 aluminum alloy powder (particle size 25 microns) 78

[0052] The preparation method of a rare earth modified aluminum-based boron carbide material comprises the following steps:

[0053] (1) Powder pre-treatment, the 6061 aluminum alloy powder is subjected to pre-oxidation treatment in an oxygen-containing atmosphere, and the treatment temperature is 250°C;

[0054] (2) Powder ball milling, the pre-oxidized powder obtained in step (1), boron carbide powder, and rare earth oxide powder are fully ball milled and mixed in a polyurethane ball mill tank, and the ball mill time is 16 hours. The ball mill in the polyurethane ball mill tank The ball is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap