High-tear-strength water-resistant non-woven fabric grinding material as well as preparation method and application thereof

A high tear strength, abrasive material technology, applied in applications, textiles and papermaking, cleaning equipment, etc., can solve problems such as low tear strength polyurethane, and achieve high tear strength, strong wear resistance, and reduced polishing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail in conjunction with specific embodiments.

[0023] The invention aims at the problem that the scouring pad products in the prior art have good bonding performance but are brittle, and polyurethane has poor water resistance because of its characteristic of being easy to react with water, and proposes a water-resistant non-woven abrasive material with high tear strength.

[0024] preferred embodiment

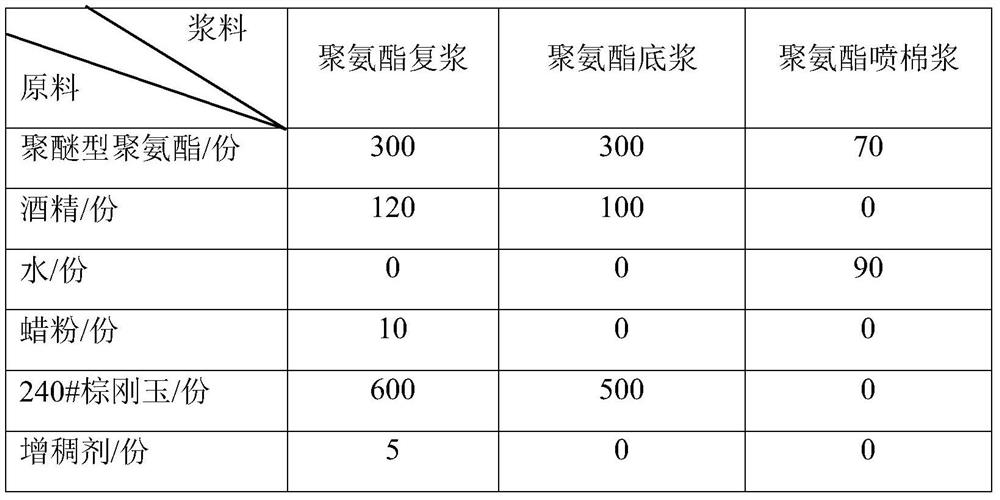

[0025] The high-tear strength water-resistant non-woven abrasive material of this embodiment includes a base material and a slurry, wherein the base material is made of nylon fibers with excellent wear resistance, and the nylon fibers are processed into a three-dimensional The network structure, the structure is more stable and uniform, greatly improving its mechanical properties. The slurry includes polyurethane s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com