Automatic mortar spraying machine

A spraying machine and mortar technology, applied in the direction of construction, building construction, etc., can solve the problems of workers' randomness in operation, uneven spraying quality, waste of steel pipes and wood, etc., and achieve high construction efficiency, uniform spraying, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

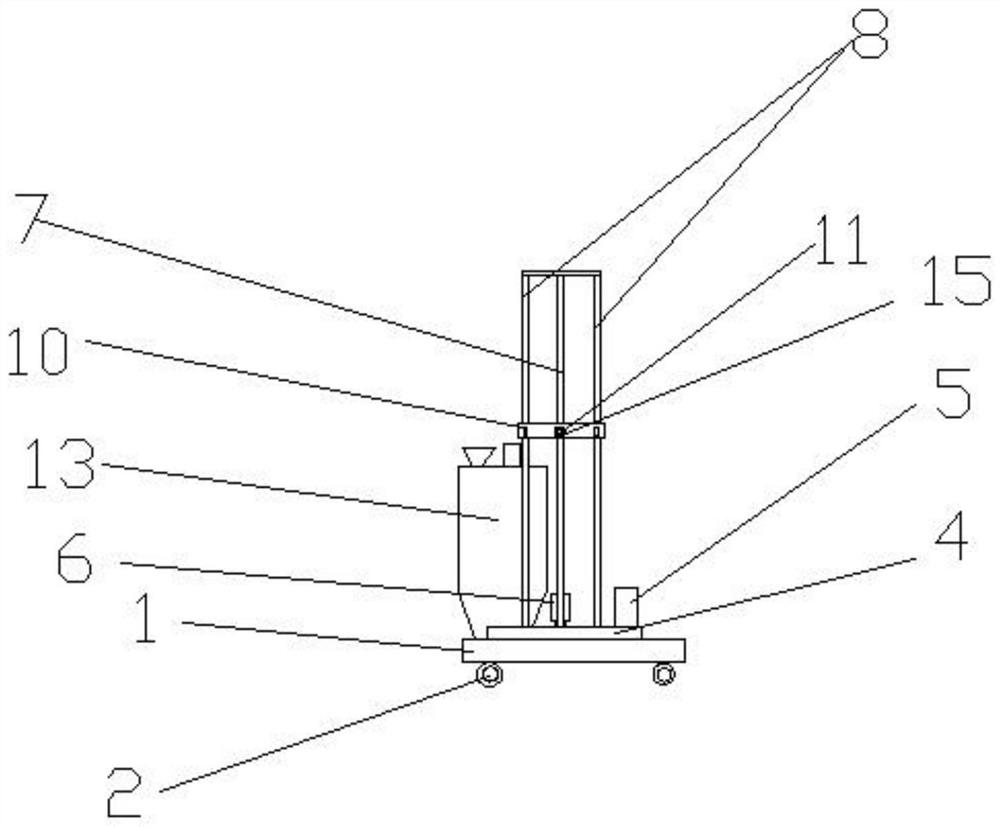

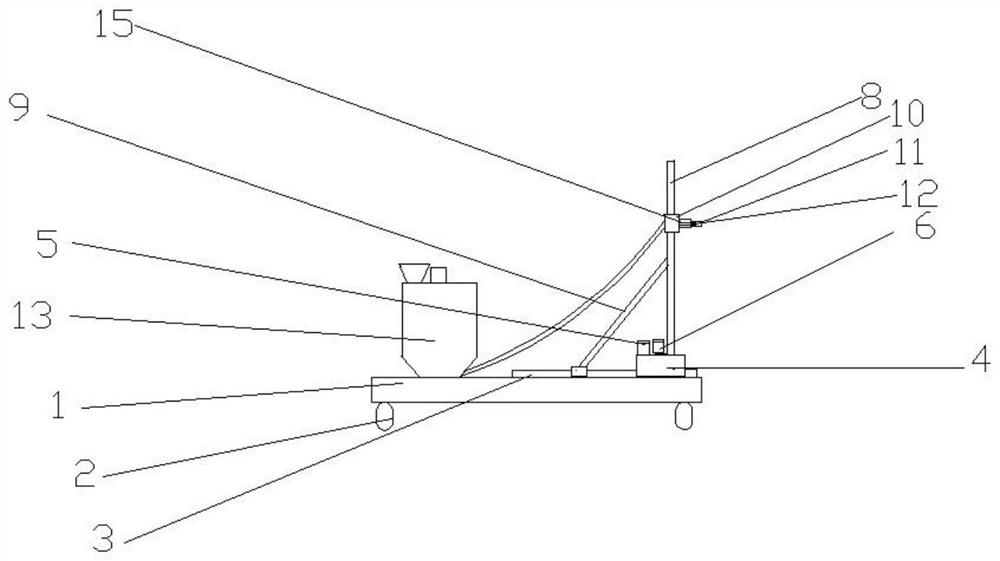

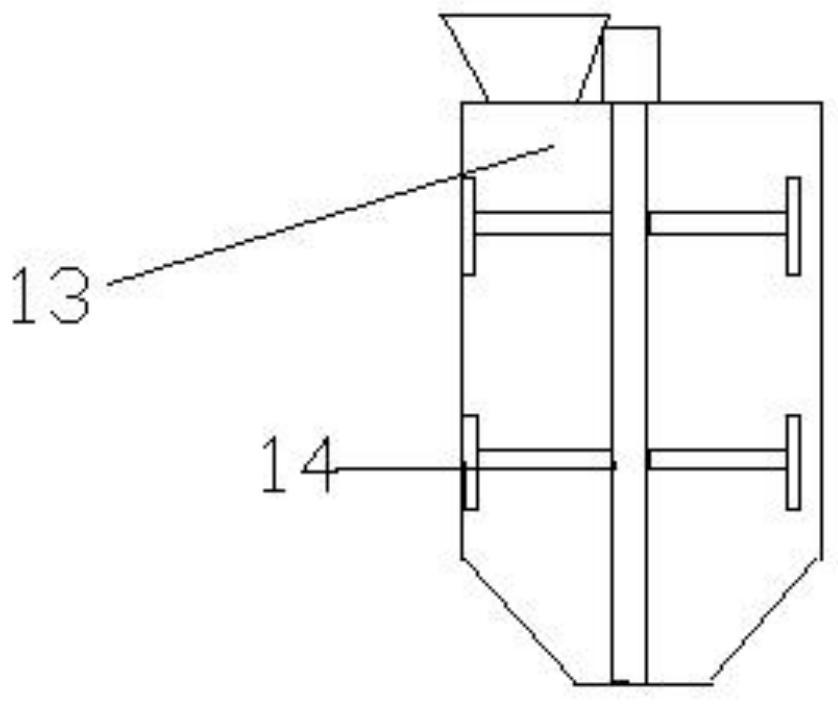

[0019] like Figure 1 to Figure 4 As shown, an automatic mortar spraying machine includes a base plate 1, a spray gun 11, a diaphragm pump, a controller and a display screen. A plurality of wheels 2 are arranged below the base plate 1, and one of the wheels 2 is connected to the first motor through gears. , the bottom plate 1 is provided with a stirring tank 13, the stirring tank 13 communicates with the spray gun 11 through a pipeline, the spray gun 11 communicates with the diaphragm pump, the base plate 1 is also provided with a guide rail 3, and the guide rail 3 is provided with There is a slide 4, the slide 4 is connected with the second motor 5, the slide 4 is provided with a lead screw 7, the lead screw 7 is connected with the third motor 6, the lead screw 7 is provided with a slide Block 10, described slide block 10 is provided with sensor 15 and spray gun 11, and described spray gun 11 is connected with rotary cylinder 12, and described controller is connected with des...

Embodiment 2

[0030] An automatic mortar spraying machine, comprising a base plate 1, a spray gun 11, a diaphragm pump, a controller and a display screen, a plurality of wheels 2 are arranged below the base plate 1, and one of the wheels 2 is connected to a first motor through a gear, and the The bottom plate 1 is provided with a stirring tank 13, the stirring tank 13 communicates with the spray gun 11 through a pipeline, the spray gun 11 communicates with the diaphragm pump, and the base plate 1 is also provided with a guide rail 3, and the guide rail 3 is provided with a sliding seat 4. The slider 4 is connected to the second motor 5, the slider 4 is provided with a screw 7, the screw 7 is connected to the third motor 6, the screw 7 is provided with a slider 10, Described slide block 10 is provided with sensor 15 and spray gun 11, and described spray gun 11 is connected with rotary cylinder 12, and described controller is connected with described diaphragm pump, spray gun 11, display scree...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap