Cement-based mat for composite board and production process of cement-based mat

A production process and cement-based technology, applied in the field of cement-based thin felt for composite boards and its production process, can solve the problems of poor strength, low cohesive strength, easy delamination, etc. Increase the effect of mechanical riveting and improve the cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

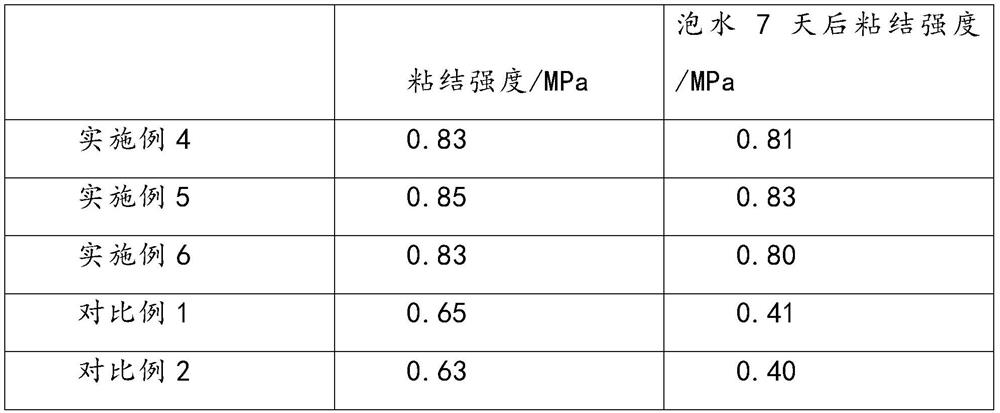

Examples

Embodiment 1

[0020] Described reinforcing fiber comprises the following steps to make:

[0021] Step S1, calcining the basalt fiber at 300°C for 2h, then raising the temperature to 450°C, and continuing to calcinate for 2h to obtain the treated basalt fiber for later use; disperse the graphene oxide in deionized water, and ultrasonically disperse it in an ice-water bath to prepare The dispersion was obtained for later use; 3,3',4,4'-benzophenone tetracarboxylic acid and 4,4'-diaminodiphenyl ether were sequentially added to N,N-dimethylformamide, and stirred at a uniform speed until Dissolve, let stand for 10min, prepare reaction liquid, set aside, control the dosage ratio of graphene oxide and deionized water to be 3g: 50mL, 3,3',4,4'-benzophenone tetracarboxylic acid and 4,4' -The molar ratio of diaminodiphenyl ether is 1:1, and the consumption ratio of 3,3',4,4'-benzophenone tetracarboxylic acid and N,N-dimethylformamide is 1g:50mL;

[0022] Step S2, slowly drop the reaction liquid into...

Embodiment 2

[0024] Described reinforcing fiber comprises the following steps to make:

[0025] Step S1, calcining the basalt fiber at 300°C for 2h, then raising the temperature to 450°C, and continuing to calcinate for 2h to obtain the treated basalt fiber for later use; disperse the graphene oxide in deionized water, and ultrasonically disperse it in an ice-water bath to prepare The dispersion was obtained for later use; 3,3',4,4'-benzophenone tetracarboxylic acid and 4,4'-diaminodiphenyl ether were sequentially added to N,N-dimethylformamide, and stirred at a uniform speed until Dissolve, let stand for 10min, prepare reaction liquid, set aside, control the dosage ratio of graphene oxide and deionized water to be 4g: 50mL, 3,3',4,4'-benzophenone tetracarboxylic acid and 4,4' -The molar ratio of diaminodiphenyl ether is 1.1:1, and the dosage ratio of 3,3',4,4'-benzophenone tetracarboxylic acid and N,N-dimethylformamide is 1.2g:50mL;

[0026] Step S2, slowly drop the reaction liquid into ...

Embodiment 3

[0028] Described reinforcing fiber comprises the following steps to make:

[0029] Step S1, calcining the basalt fiber at 300°C for 2h, then raising the temperature to 450°C, and continuing to calcinate for 2h to obtain the treated basalt fiber for later use; disperse the graphene oxide in deionized water, and ultrasonically disperse it in an ice-water bath to prepare The dispersion was obtained for later use; 3,3',4,4'-benzophenone tetracarboxylic acid and 4,4'-diaminodiphenyl ether were sequentially added to N,N-dimethylformamide, and stirred at a uniform speed until Dissolve, let stand for 10min, prepare reaction solution, set aside, control the dosage ratio of graphene oxide and deionized water to be 5g: 50mL, 3,3',4,4'-benzophenone tetracarboxylic acid and 4,4' -The molar ratio of diaminodiphenyl ether is 1.2:1, and the consumption ratio of 3,3',4,4'-benzophenone tetracarboxylic acid and N,N-dimethylformamide is 1.5g:50mL;

[0030] Step S2, slowly drop the reaction liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com