Stable and rapid jacking construction method for box culvert under large excavation face

A technology of excavation face and box culvert, which is applied in the field of box culvert jacking construction method, which can solve the problems of incoherence, uneven jacking force, and large deviation of box culvert, etc., so as to reduce the excavation area and ensure the construction quality , The effect of reducing the construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

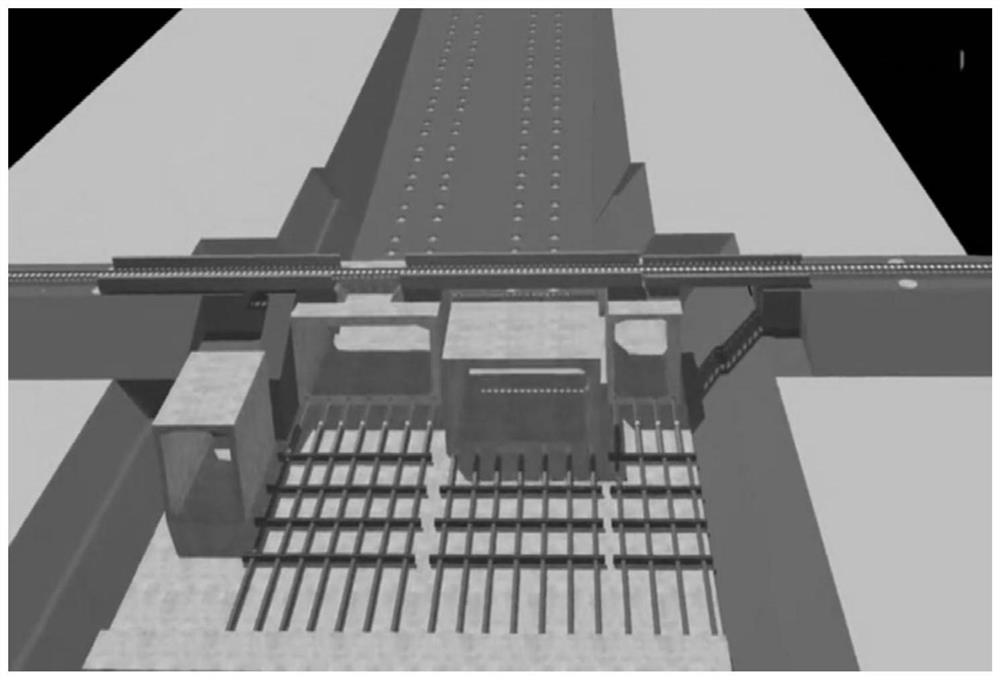

Image

Examples

Embodiment 1

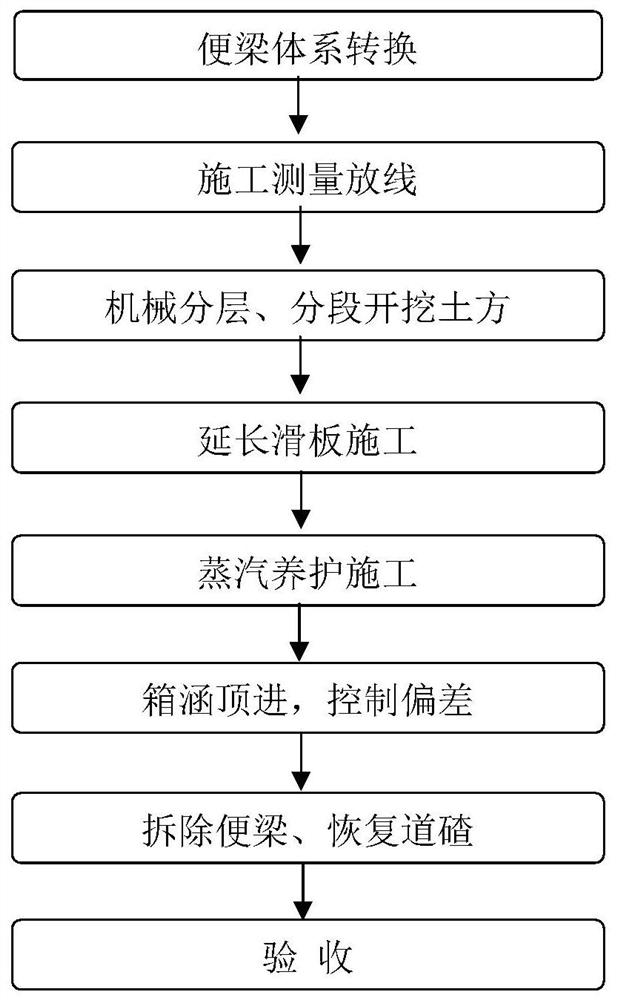

[0042] 1. The construction process of this embodiment

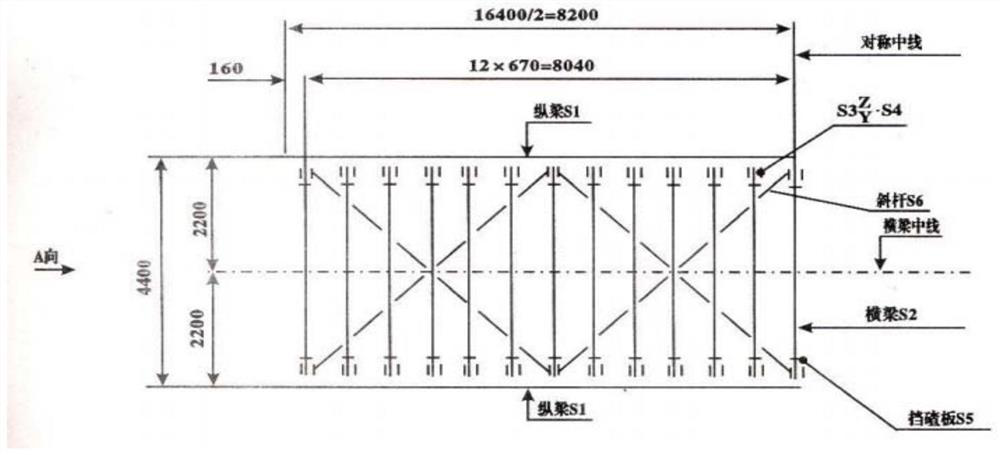

[0043] This embodiment is jacking four-section box culvert, the box culvert spans are 6m, 13m, 13m, 6m respectively, by optimizing and adjusting the construction process of digging and jacking in traditional jacking construction, jacking in and out of the soil at the same time, the creative Divide the "digging" and "jacking", and carry out the excavation and transportation of large-area jacking soil for each section of the box culvert, to eliminate the uneven frictional resistance caused by the soil to the box culvert during the jacking process, and then increase the sliding plate The extended length reaches the end position of the jacking. Using the strong bearing capacity of the extended slide plate and the design advantages of the steel slide rail, the jacking construction can be continuously operated, the deviation can be corrected in time, and the jacking can be successfully completed.

[0044] Before jacking constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com