Vapor chamber

A technology of temperature chambers and substrates, applied in cooling/ventilation/heating renovation, electrical components, lighting and heating equipment, etc., which can solve the problems of poor heat transfer efficiency, scattered working fluid, and easy mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The implementation of the present invention will be described below by means of specific specific examples, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the content disclosed in this description, and can also use other different specific examples implement or apply.

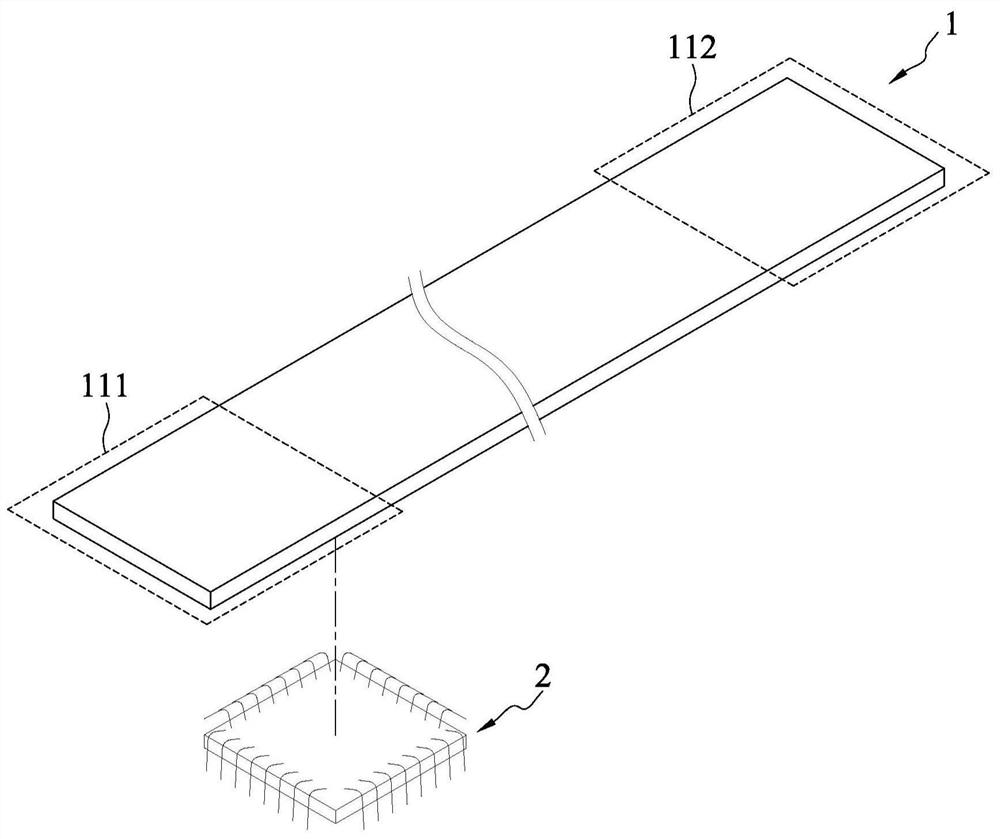

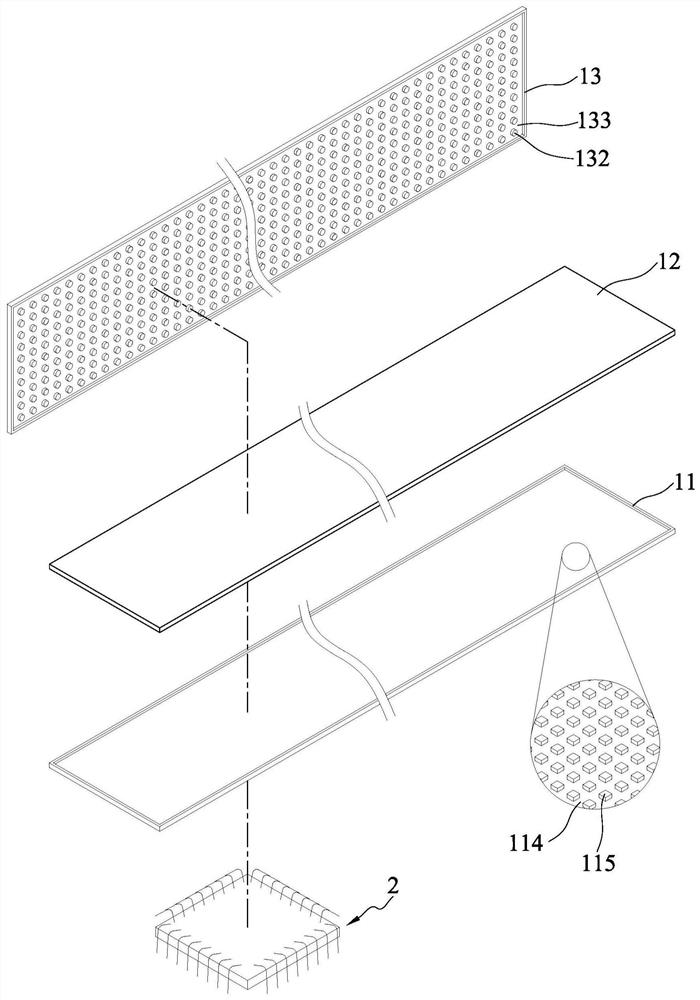

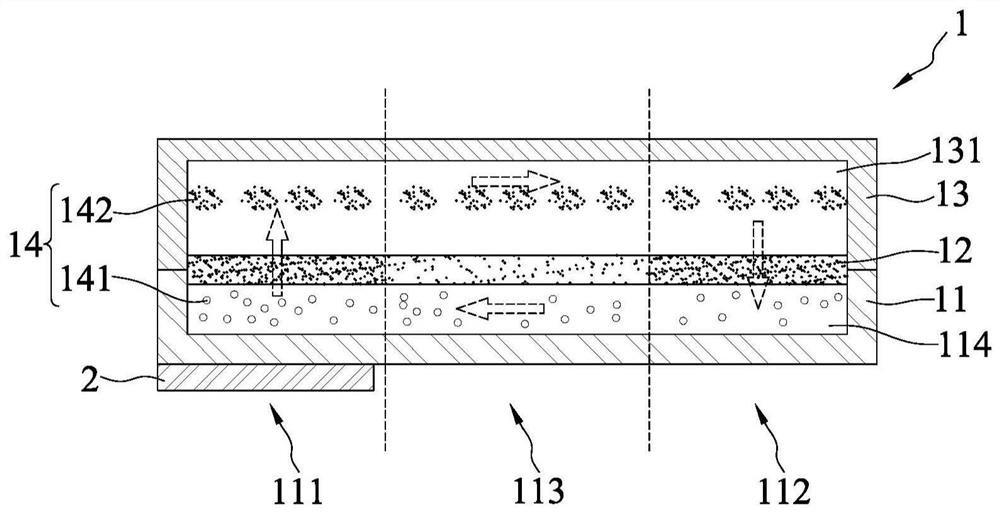

[0075] see Figure 1A , Figure 1B , figure 2 and image 3 , the vapor chamber 1 of the present invention includes a first substrate 11, a flow guide layer 12 and a second substrate 13, and the vapor chamber 1 of the present invention can contact at least one heat source 2, and the vapor chamber 1 can define a corresponding An evaporation area 111 and at least one condensation area 112 of the heat source 2 , and an adiabatic area 113 except the evaporation area 111 and the condensation area 112 . Hereinafter, a heat source 2 , an evaporation zone 111 , a condensation zone 112 and an adiabatic zone 113 are used for illus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com