Locking and sealing device for blow molding of plastic pipeline

A blow molding and sealing device technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of unsuitable high-pressure working conditions, blank tube sealing not mentioned, not considered, etc., to achieve easy removal mold, avoid damage, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

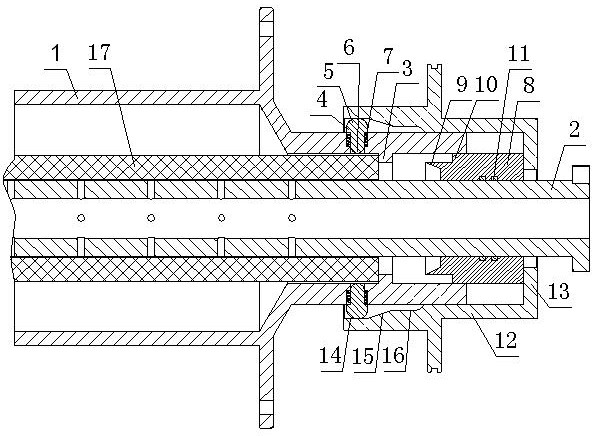

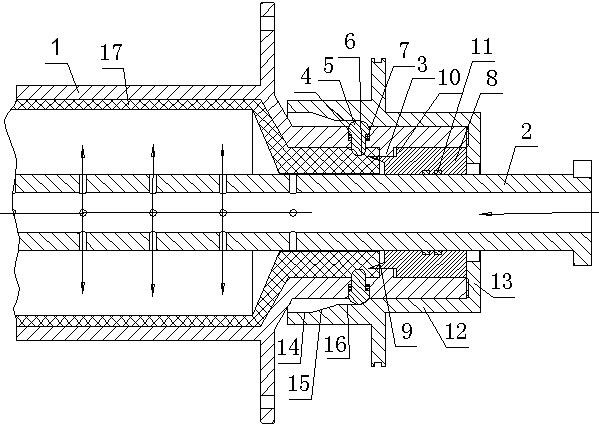

[0014] like figure 1 As shown, the plastic pipe blow molding locking and sealing device of this embodiment includes a molding mold cylinder 1, an inflation mandrel 2 passing through the molding mold cylinder 1; the inner circumference of the molding mold cylinder 1 is fixedly provided with a convex ring 3, and There are several radial stepped holes in the forming mold barrel 1 on the axial inner side of the convex ring, and special-shaped steel balls 4 are slid in each step. The radially outer end 5 of the special-shaped steel balls 4 is arc-shaped and is located Radially outside, the middle part of the special-shaped steel ball 4 is provided with a step, and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com