Oil mist recovery device

A recovery device and oil mist technology, which is applied in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of corrosion, short residence time, short gas flow path, etc., to improve distribution uniformity and reduce airflow resistance. , the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

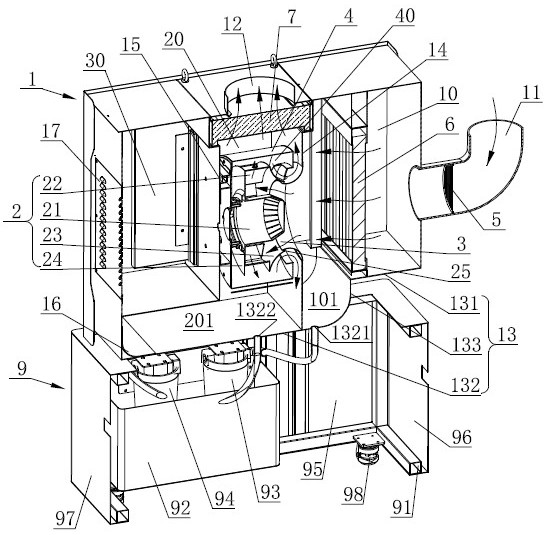

[0042] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

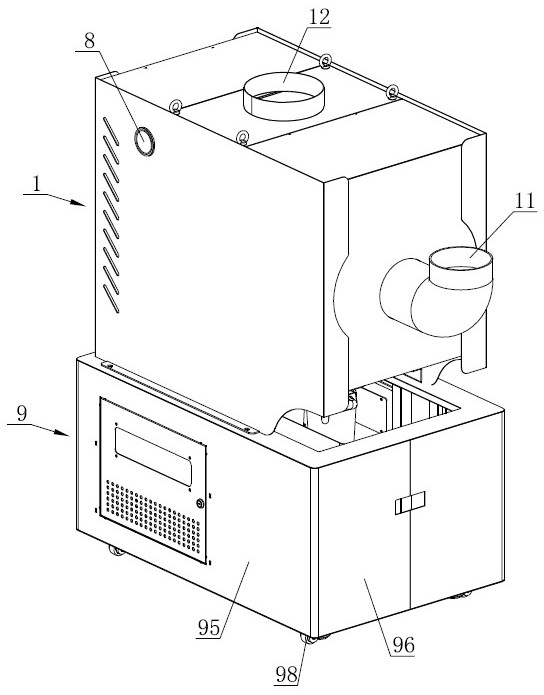

[0043] Such as figure 1 , figure 2 As shown, the recovery device of the present invention is arranged on the top surface of the chassis 9 .

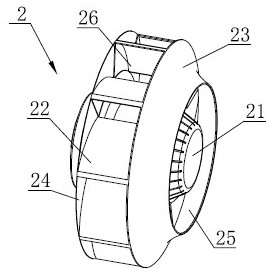

[0044] Such as figure 1 , figure 2 As shown, the front side of the casing 1 of the recovery device is provided with an air intake pipe 11 , and the top surface of the casing 1 is provided with an air outlet 12 . Such as figure 2 As shown, a first filter element 5 is vertically arranged in the air intake pipe 11 along the radial direction, and the first filter element 5 is a metal filter screen, which can perform a first filtering process on the inhaled airflow.

[0045] Such as figure 2 As shown, a first partition 14 and a second partition 15 are arranged at intervals from front to back in the housing 1, and the first partition 14 and the second partition 15 divide the inner cavity of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com