Preparation technology for heating cigarette material by composite method

A technology of cigarette material and preparation process, which is applied in the direction of preparing tobacco, tobacco, processing tobacco, etc., can solve the problems of unfavorable cigarette sensory quality, tensile strength of cigarette material, concentration of coating solution not too high, increasing cigarette preparation cost, etc. Superior processing performance, high coating efficiency and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

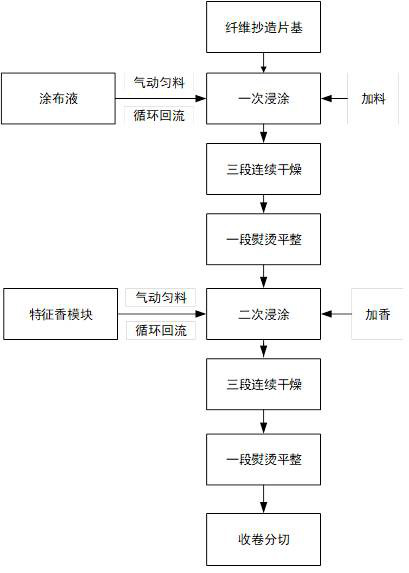

Method used

Image

Examples

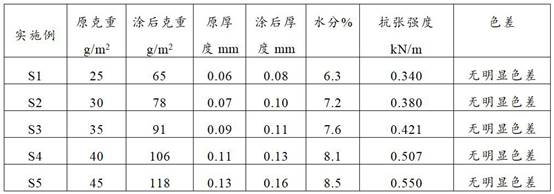

Embodiment 1

[0026] Select a width of 300mm and a weight of 25g / m 2 , Tensile strength of 0.4kN / m fiber sheet base as carrier.

[0027]Prepare the coating liquid and the characteristic fragrance module respectively, measure the viscosity of the coating liquid, set the stirring temperature to 60±2°C, and the stirring speed to 50±2r / min, and make a section of the coating liquid in a closed storage tank with a water bath heating function. Heat and stir.

[0028] Set the second-stage stirring speed to 30±2r / min, and stir the second-stage characteristic fragrance module at room temperature.

[0029] Set the convective compressed air pressure to 0.2Mpa, and the cycle backflow rate to 5L / min.

[0030] Set the temperature ranges of the first, second and third stages to 95°C, 95°C, and 95°C respectively, and set the temperature ranges of the fourth, fifth, and sixth stages to 55°C, 55°C, and 55°C respectively.

[0031] Set the first-stage ironing temperature to 95°C, and the second-stage ironing...

Embodiment 2

[0034] Select a width of 400mm and a weight of 30g / m 2 , Tensile strength of 0.5kN / m fiber sheet base as carrier.

[0035] Prepare the coating liquid and the characteristic fragrance module respectively, measure the viscosity of the coating liquid, set the stirring temperature to 65±2°C, and the stirring speed to 55±2r / min, and heat a section of the coating liquid in a closed storage tank with a water bath heating function. Heat and stir.

[0036] Set the second-stage stirring speed to 32±2r / min, and carry out normal temperature stirring on the second-stage characteristic fragrance module.

[0037] Set the convective compressed air pressure to 0.15Mpa, and the circulation rate to 6L / min.

[0038] Set the temperature ranges of the first, second, and third stages to 100°C, 100°C, and 100°C respectively, and set the temperature ranges of the fourth, fifth, and sixth stages to 60°C, 60°C, and 60°C, respectively.

[0039] Set the first-stage ironing temperature to 100°C, and the...

Embodiment 3

[0042] Select a width of 500mm and a weight of 35g / m 2 , Tensile strength of 0.5kN / m fiber sheet base as carrier.

[0043] Prepare the coating liquid and the characteristic fragrance module respectively, measure the viscosity of the coating liquid, set the stirring temperature to 65±2°C, and the stirring speed to 55±2r / min, and heat a section of the coating liquid in a closed storage tank with a water bath heating function. Heat and stir.

[0044] Set the second-stage stirring speed to 32±2r / min, and carry out normal temperature stirring on the second-stage characteristic fragrance module.

[0045] Set the convective compressed air pressure to 0.15Mpa, and the circulation rate to 6L / min.

[0046] Set the temperature ranges of the first, second, and third stages to 100°C, 105°C, and 100°C respectively, and set the temperature ranges of the fourth, fifth, and sixth stages to 65°C, 65°C, and 65°C, respectively.

[0047] Set the first-stage ironing temperature to 95°C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com