Quickly-assembled anti-deformation steel structure curtain wall and construction method thereof

A steel structure and anti-deformation technology, which is applied to the parts of lighting devices, walls, building components, etc., can solve the problem of inability to ensure the firmness of the connection between the connection seat and the wall and the ground, the inability to guarantee the normal use of the glass curtain wall, and the absence of buffers Mechanism and other problems, to achieve the effect of convenient assembly, ensuring firmness and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

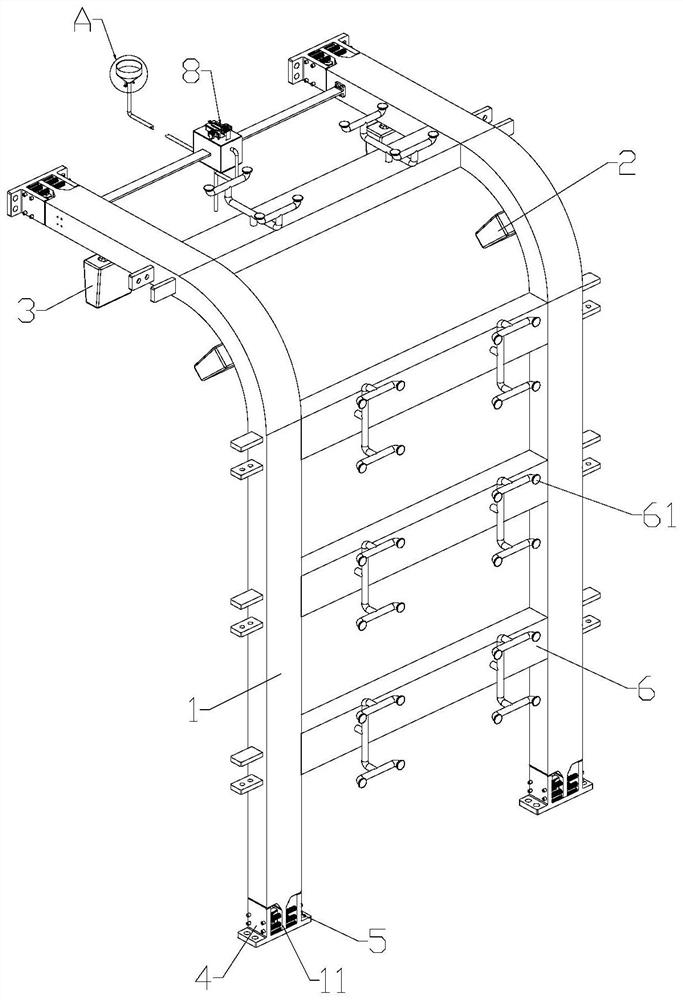

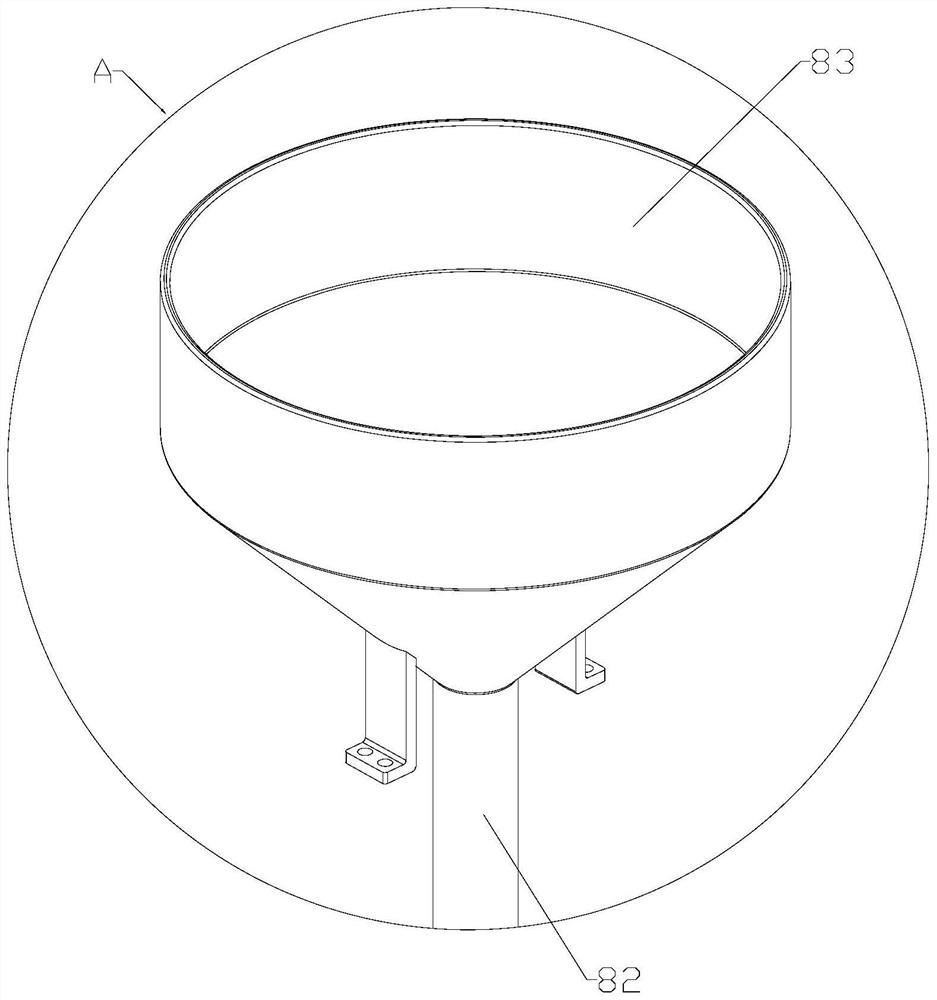

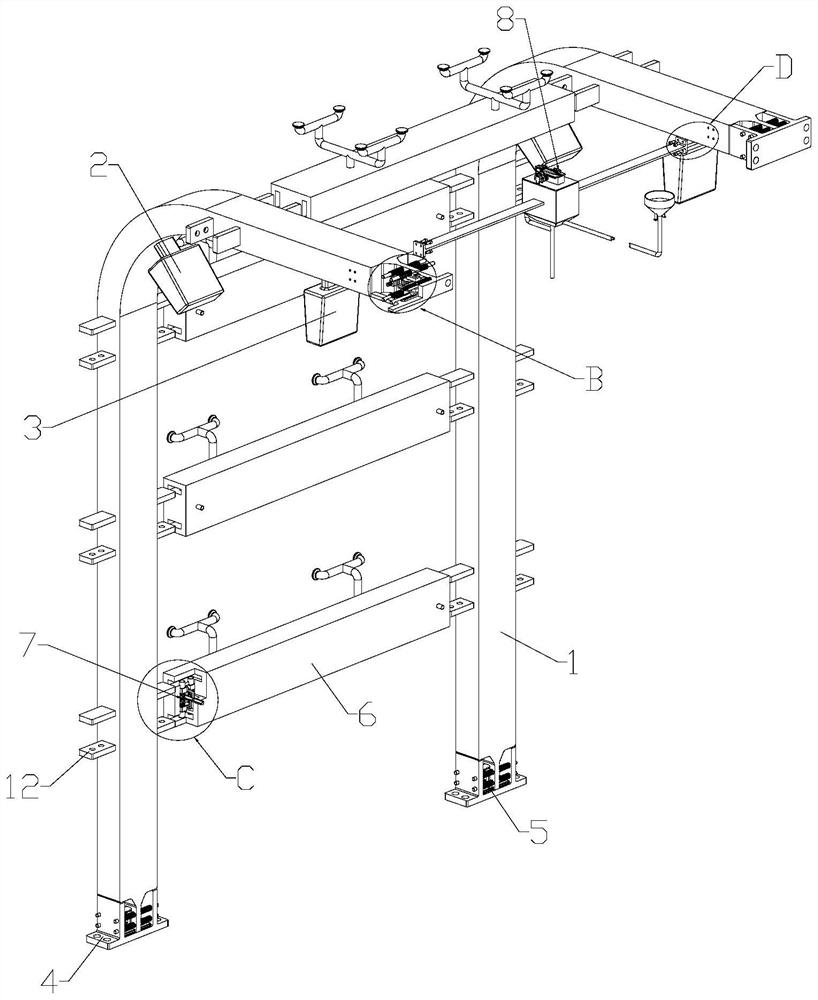

[0034] Example: such as Figure 1 to Figure 10 As shown, the present invention provides a fast-installation anti-deformation steel structure curtain wall, including a stand 1, a first lighting lamp 2 and a second lighting lamp 3 are fixedly installed on the stand 1, and the stand 1 Connectors 11 are integrally formed at both ends, and a connecting seat 4 is slidably arranged on the connecting head 11. A through hole is provided on the connecting seat 4 to facilitate connecting it with the wall and the ground. The inner side of the connecting seat 4 is provided with a symmetrical Distributed slide rails, the connecting head 11 is provided with a chute, the chute is slidably sleeved on the sliding rail, a buffer mechanism 5 is provided between the connecting seat 4 and the connecting head 11, and a buffer mechanism 5 is provided between the adjacent stand 1 A horizontal frame 6 is detachably provided, and one side of the horizontal frame 6 is fixedly equipped with symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com