A high-voltage multi-electrode device

An electrode device and multiple technologies, applied in coil devices, induction heating and other directions, can solve the problems of limiting the total voltage simulation range of chip arc heaters, unable to effectively shunt large current loads, etc., so as to reduce the voltage difference and effectively shunt current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

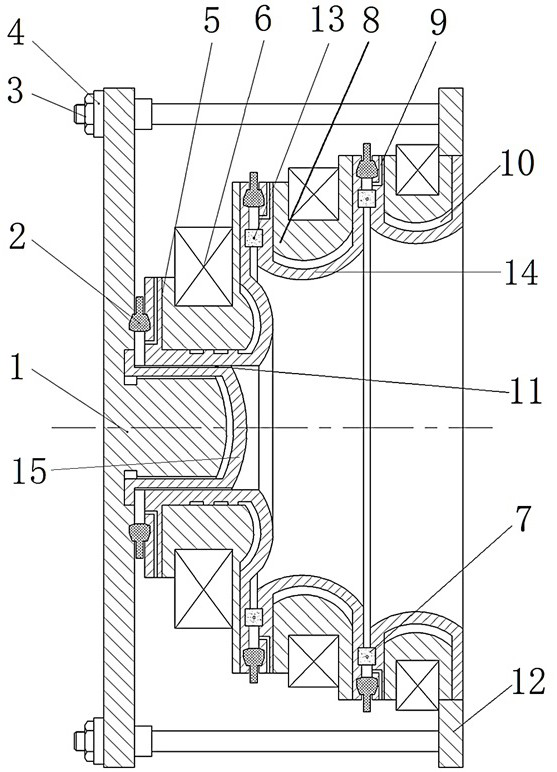

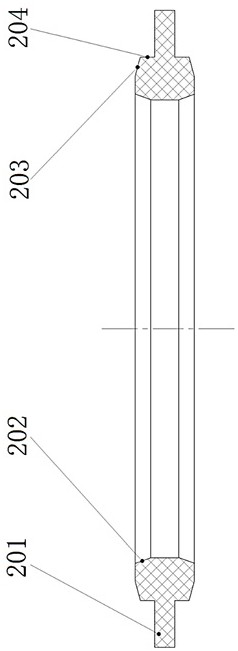

[0033]In this embodiment, N=3, the back cover 1, the sealing insulating ring 2, the electrode piece 5, the excitation coil 6, and the intake ring 7 are connected and compressed by the connecting bolt group 3 to realize the insulation and sealing between the electrode pieces 5, and the insulating sleeve 4 is installed on Insulation is realized between the rear cover 1 and the connecting bolt group 3 . Both the back cover 1 and the electrode sheet 5 are sandwich water-cooled structures, and the inner shell of the electrode sheet 5 is made of oxygen-free copper material. The water-cooled part of the back cover 1 is inserted into the center electrode sheet 15, and the cylindrical part of the center electrode sheet 15 is processed with a rotating air channel 11 on the circumferential surface, which generates a rotating air flow during operation and drives the arc to rotate. The sealing insulating ring 2 is made of polytetrafluoroethylene material, and the sealing is realized by def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com