Method for composting lignocellulose waste and preparing organic fertilizer rich in humic acid

A technology for lignocellulose and waste, which is applied in the field of decomposing lignocellulose waste and preparing organic fertilizer rich in humic acid, can solve the problems of long decomposing time, insignificant product advantages and low degree of humification, etc. Comprehensive, long-term solution, and strong vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

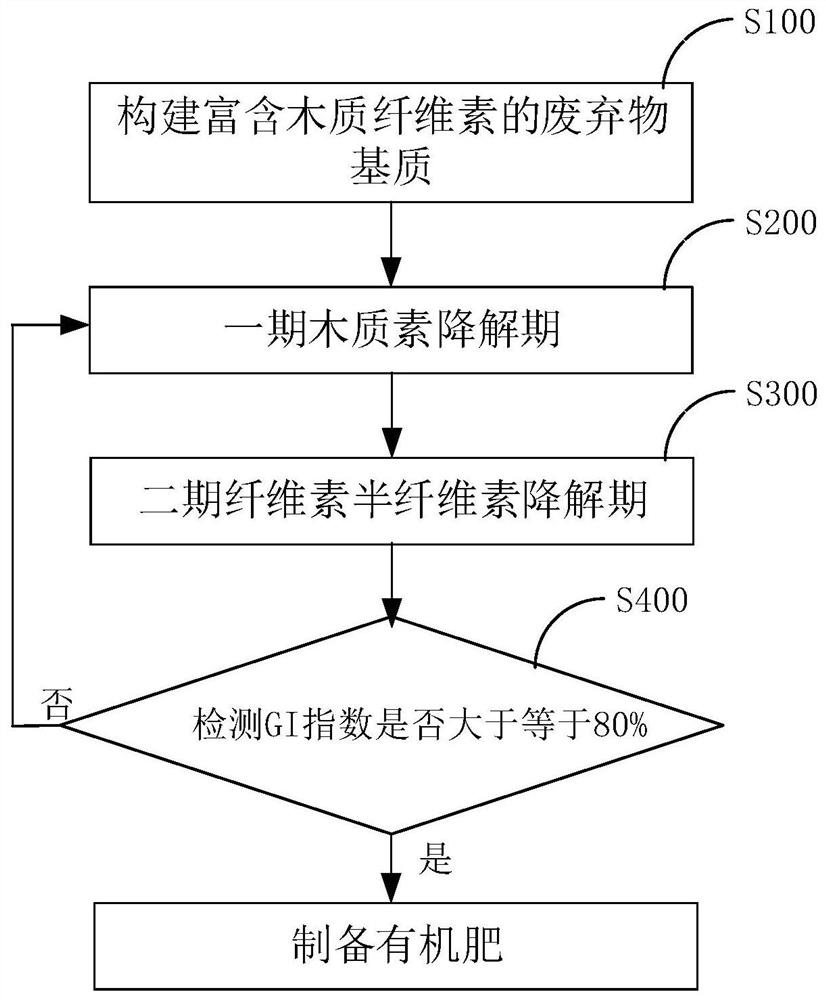

[0093] On the other hand, the embodiment of the present application provides a preparation method of an organic fertilizer rich in black humic acid, which is characterized in that, comprising the following steps:

[0094] The waste substrate is treated by the decomposing method described in the above embodiment;

[0095] The prepared humic acid-rich organic fertilizer substrate is adjusted by using KOH to adjust the pH value of the humic acid-rich organic fertilizer substrate to 11 to 12, and the clear liquid and the humic acid-rich organic fertilizer substrate are filtered and separated. solid matter;

[0096] Using wood vinegar liquid-inorganic acid mixed solution to adjust the pH value of clear liquid to 3 to 5, to obtain two rounds of clear liquid and sediment, and concentrating the moisture content of sediment to less than 25% to obtain an organic fertilizer rich in black humic acid.

[0097] The wood vinegar-inorganic acid mixed solution can be wood vinegar-hydrochloric...

Example Embodiment

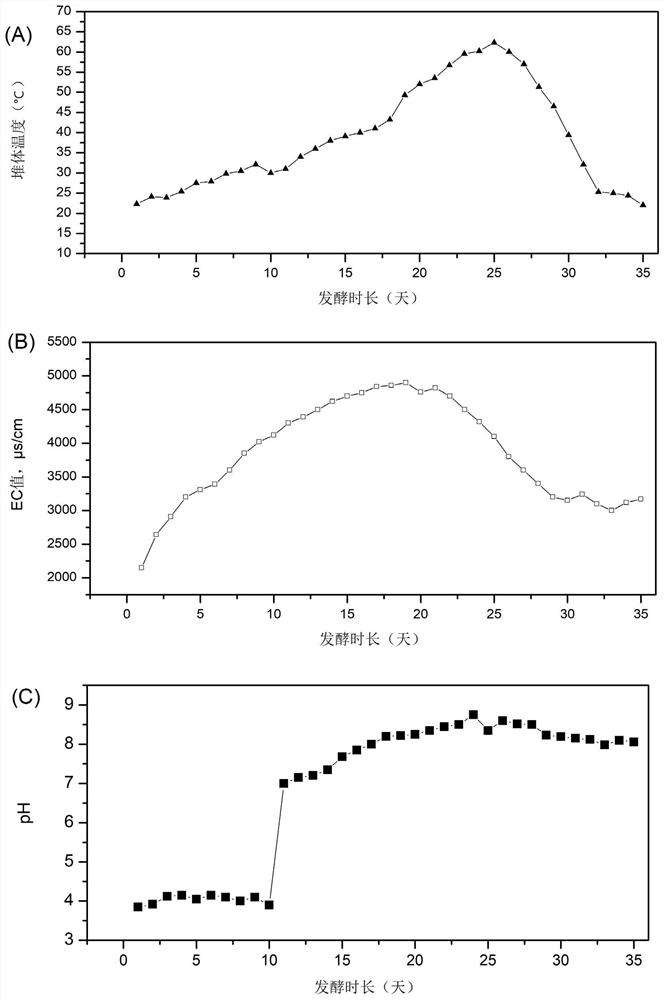

[0106] Example 1

[0107] A method for decomposing distiller's grains and rice husks, comprising the following steps:

[0108] S101, culturing various strains

[0109] Grow the strains to the highest biomass density using common media suitable for each strain. Species include P. chrysanthemum, shiitake mushroom, Hericium erinaceus, Geotrichum candidum, Aspergillus niger, Rhododendron tannophilus, Acetobacter tannophilus, Acetobacter, Lactobacillus plantarum, Kluyveromyces marxianus, Candida tropicalis, Candida jiyemeni, Pichia pastoris, Bifidobacterium longum, Bacillus subtilis for feeding, Trichoderma viride;

[0110] The liquor koji is a Maotai liquor liquor koji from Maotai Town, Guizhou Province.

[0111] S102, construct waste matrix

[0112] Prepare 75kg of dried rice husk vinegar grains, of which 15kg is crushed to a particle size of 1mm, the crushed vinegar grains are mixed with the uncrushed vinegar grains, and 0.75kg of cottonseed hulls, 0.75kg of soybean meal pow...

Example Embodiment

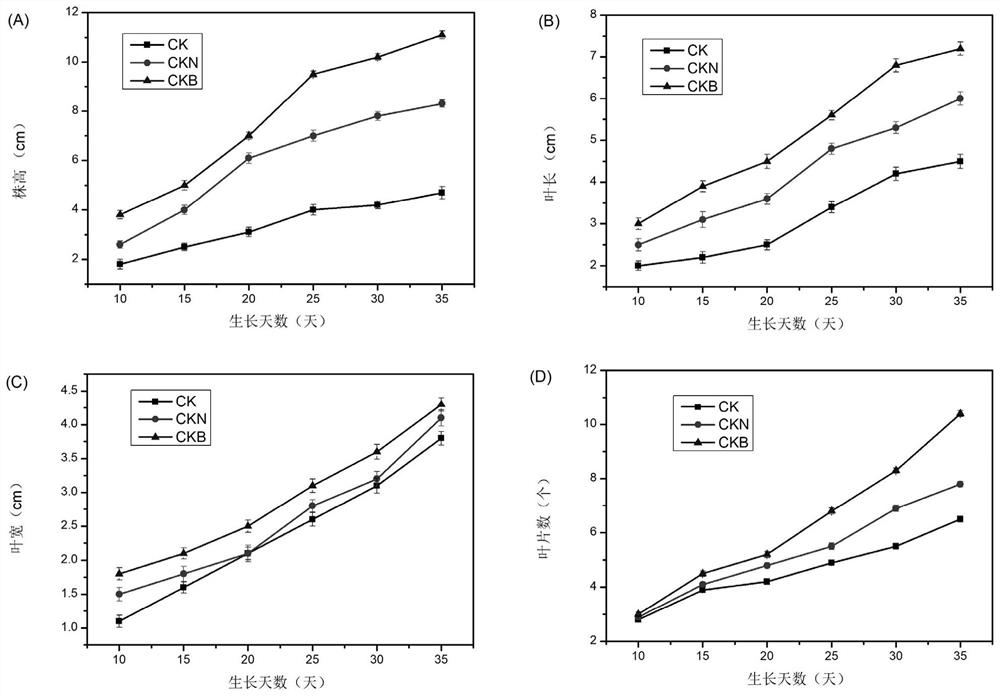

[0126] Example 2

[0127] A kind of organic fertilizer rich in humic acid and preparation method thereof

[0128] Adopt the decomposing method of distiller's grains rice husk described in embodiment 1 to process waste substrate;

[0129] The pH value of the decomposed waste substrate is adjusted to 11 by KOH solution, and the clear liquid and solids in the waste substrate are filtered and separated;

[0130] Using the wood vinegar liquid-hydrochloric acid mixture with a volume ratio of 1:1 to adjust the pH value of the solid to be 7.0, and to adjust the moisture content of the solid to be 10%, an organic fertilizer is obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap