Receiving structure for battery cells and method for producing a receiving structure for battery cells

A battery unit and accommodating structure technology, applied in the direction of batteries, electrical components, secondary batteries, etc., can solve problems such as battery structure difficulties, and achieve the effect of preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

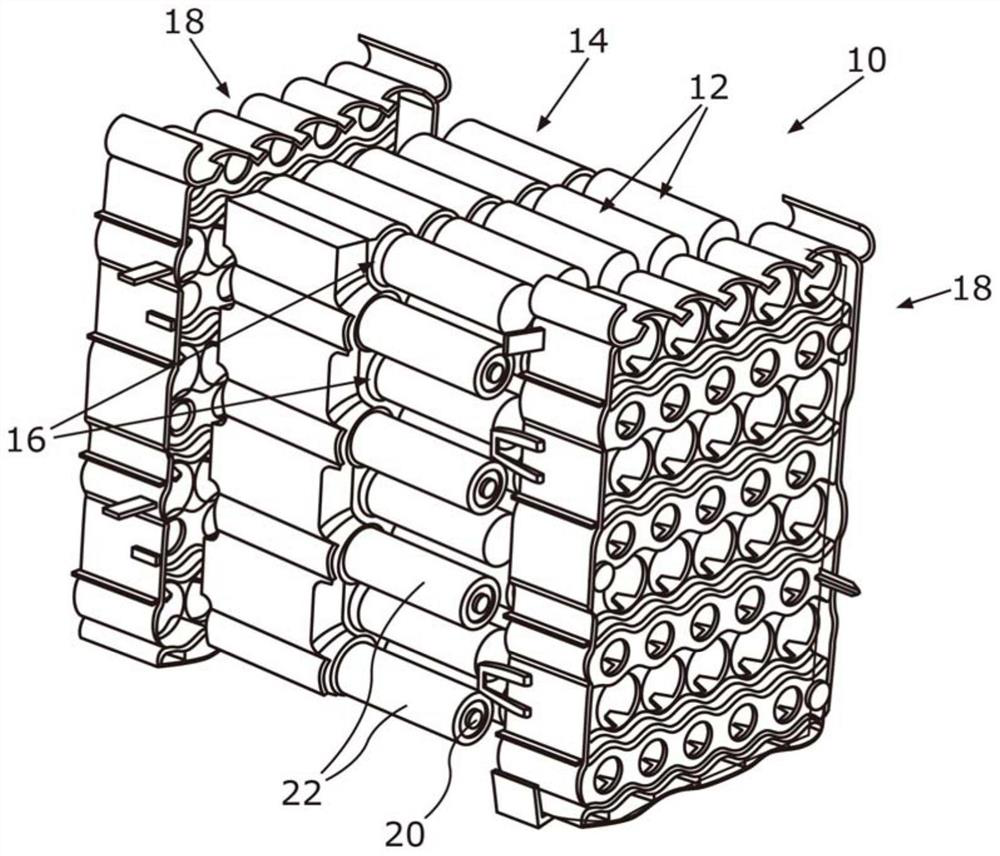

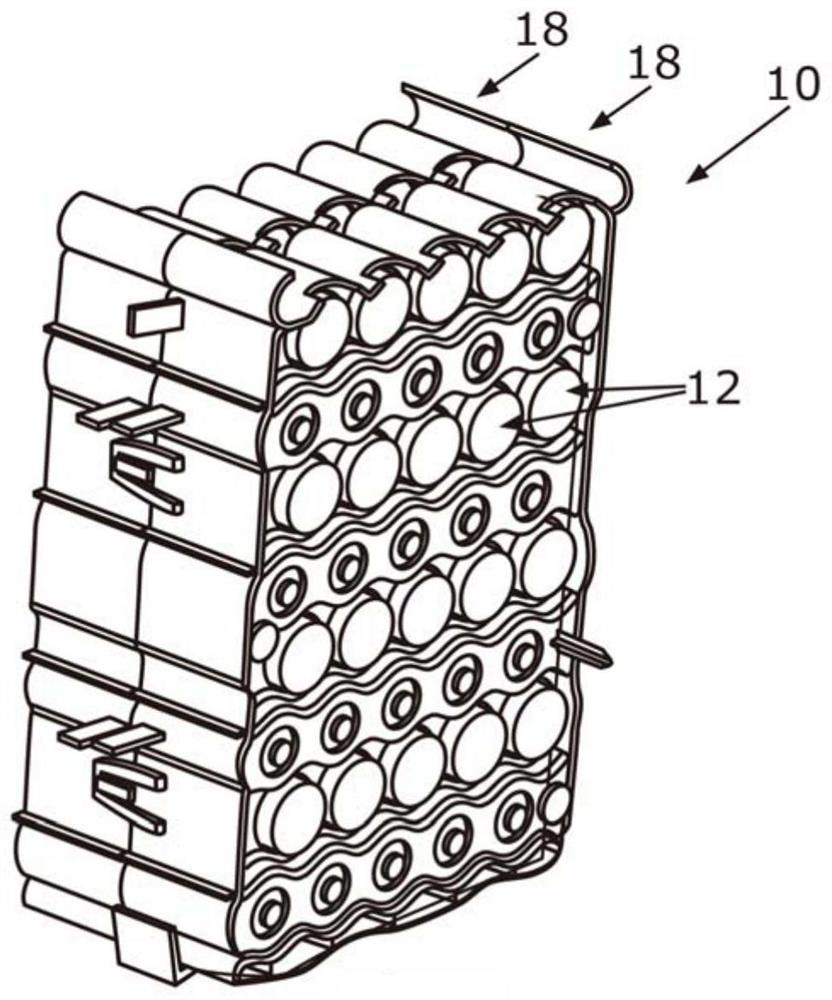

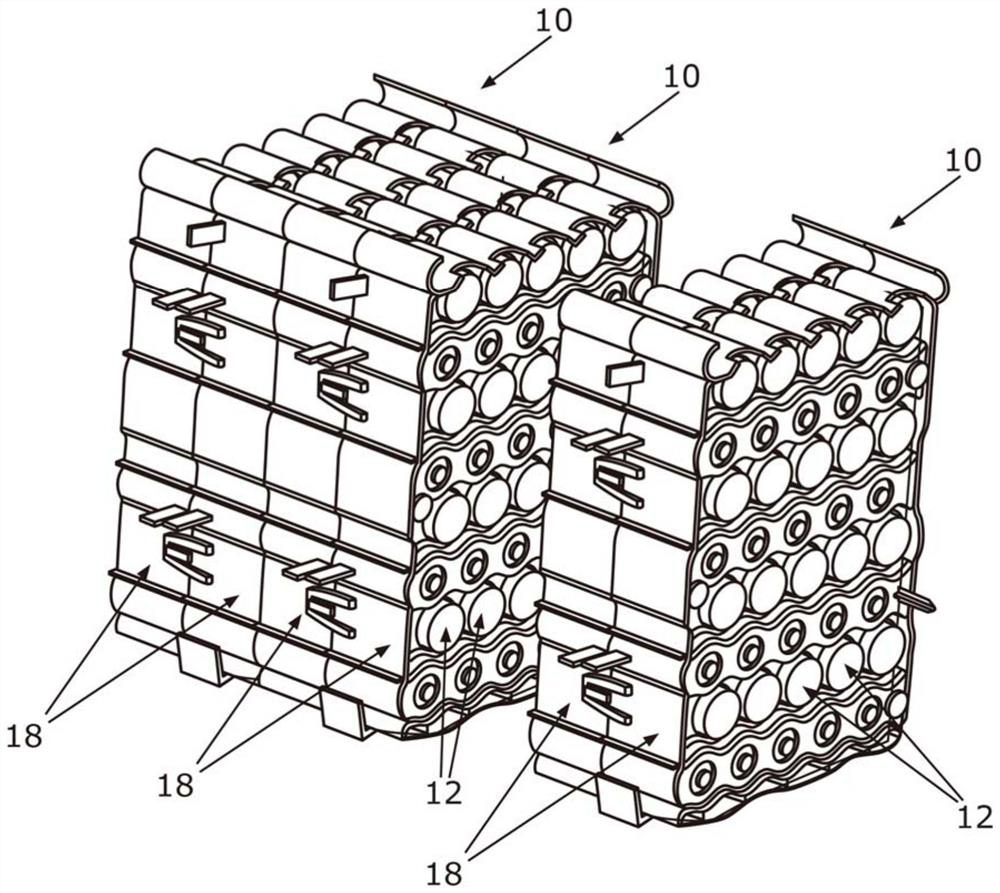

[0032] figure 1 The receiving structure 10 for the battery cell 12 is shown in an exploded perspective view. In the case shown here, the battery cells 12 are circular battery cells. However, the following explanations also apply to battery cells of different shapes, for example in the form of prismatic cells, pouch cells, etc. In particular, the battery unit 12 may be a battery unit of a high-voltage battery for an electric vehicle.

[0033] The receiving structure 10 comprises a battery cell holder 14 made of foam material having a corresponding recess 16 for receiving and fixing the corresponding battery cell 12 . The battery cell holder 14 is shaped such that when a battery cell 12 is arranged as intended in the recess 16 , at least one area is freed for the respective battery cell 12 so that a non-conductive cooling medium can flow around the respective area. In the case shown here, the battery cell holder 14 is used to accommodate the battery cells 12 which are designe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap