Touch panel, manufacturing method of touch panel and touch device

A touch panel and touch sensing electrode technology, applied in the input/output process of data processing, instruments, calculations, etc., can solve the problems of large width of the peripheral area, inability to reduce the size of the peripheral area, unfavorable general application, etc., to reduce Effects of width, good optical properties, and maintaining bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

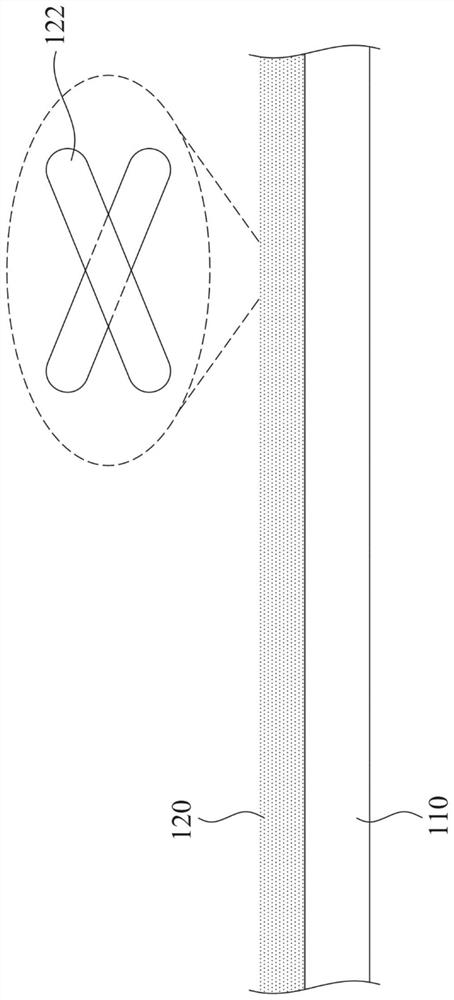

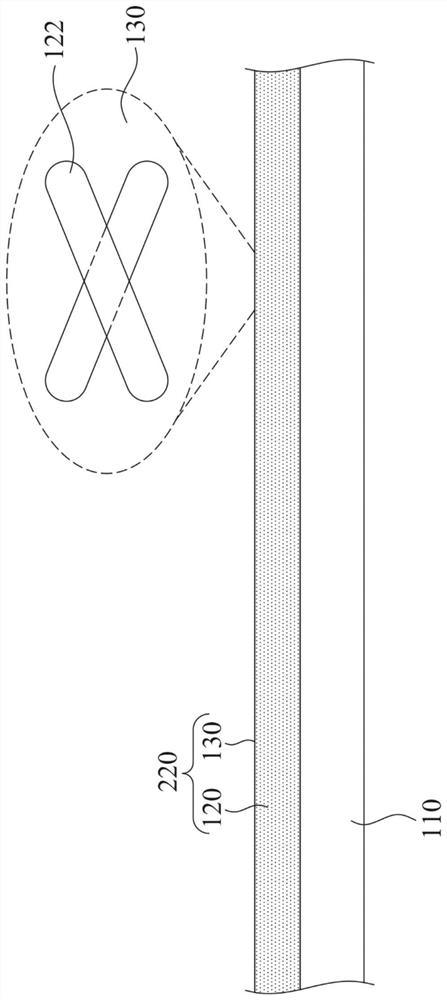

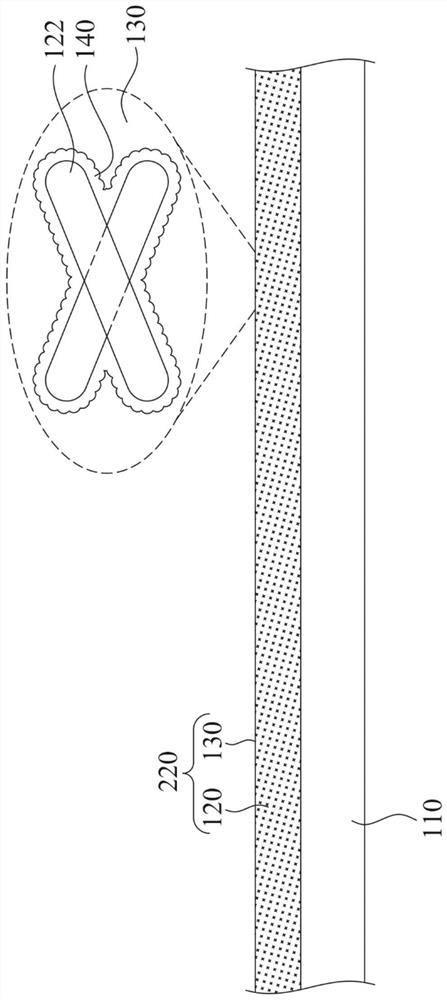

[0073] A number of implementations of the present disclosure will be disclosed below with the accompanying drawings. For the sake of clarity, many practical details will be described together in the following description. However, it should be understood that these practical details should not be used to limit the present disclosure. That is to say, in some embodiments of the present disclosure, these practical details are unnecessary, and thus should not be used to limit the present disclosure. In addition, for the sake of simplifying the drawings, some known and conventional structures and elements will be shown in a simple and schematic manner in the drawings. In addition, for the convenience of readers, the sizes of the elements in the drawings are not shown in actual scale.

[0074] Additionally, relative terms such as "lower" or "bottom" and "upper" or "top" may be used herein to describe one element's relationship to another element as shown in the figures. It will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com