Methane carbon dioxide reforming catalyst and preparation method thereof

A reforming catalyst, carbon dioxide technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of weakening catalyst carbon deposition and achieve the cost of raw materials Low cost, simple preparation method and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

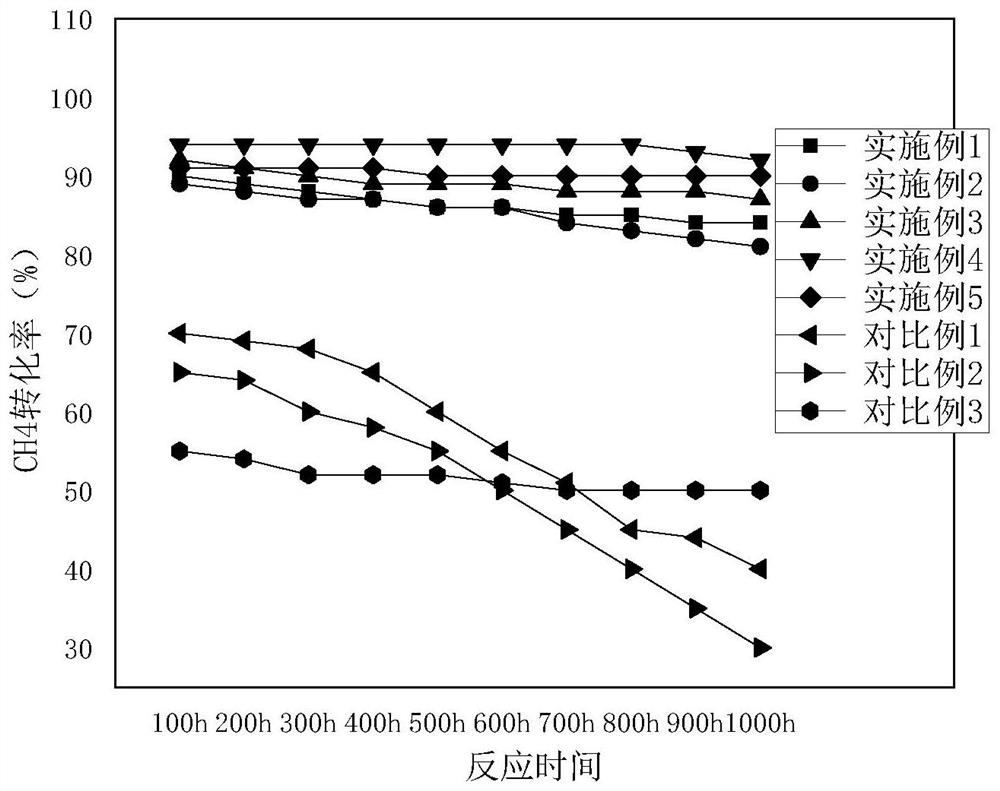

Examples

Embodiment 1

[0025] Take 0.12mol of citric acid and pour it into deionized water, mix well to form a solution. Take 0.1 mol of lanthanum nitrate and 0.1 mol of nickel nitrate and dissolve them in deionized water, then drop them into the aqueous solution of citric acid, and mix well to form a sol. Afterwards, the sol was heated to 80° C. to evaporate water, so that it gradually turned into a gel. Afterwards, the gel was dried at 80°C. The solid obtained by drying is roasted at a temperature of 900°C to obtain LaNiO 3 .

[0026] Get 0.073g of sodium nitrate and dissolve it in deionized water, mix the sodium nitrate solution with 20g of the obtained LaNiO 3 Mix to obtain a suspension, and rotate the suspension on a rotary evaporator to slowly evaporate the water to dryness, so that the alkali metal can be evenly dispersed in the LaNiO 3 surface. The solid obtained after evaporation to dryness was dried at 120°C and calcined at 450°C to obtain Na / LaNiO 3 catalyst.

[0027] The mass cont...

Embodiment 2

[0029] Take 0.12mol of citric acid and pour it into deionized water, mix well to form a solution. Take 0.09mol of lanthanum nitrate, 0.01mol of cerium nitrate, and 0.1mol of nickel nitrate and dissolve them in deionized water, then drop them into the aqueous solution of citric acid, and mix well to form a sol. Afterwards, the sol was heated to 80° C. to evaporate water, so that it gradually turned into a gel. Afterwards, the gel was dried at 90°C. The solid obtained by drying is roasted at a temperature of 800°C to obtain La 0.9 Ce 0.1 NiO 3 .

[0030] Get 0.072g Potassium Nitrate and be dissolved in the middle of deionized water, Potassium Nitrate solution and 20g obtained La 0.9 Ce 0.1 NiO 3 Mix to obtain a suspension, and carry out rotary evaporation on a rotary evaporator, so that the water is slowly evaporated to dryness, so that the potassium ions can be evenly dispersed into the La 0.9 Ce 0.1 NiO 3 surface. The solid obtained after evaporation to dryness was ...

Embodiment 3

[0033] Take 0.12mol of citric acid and pour it into deionized water, mix well to form a solution. Take 0.07mol of lanthanum nitrate, 0.03mol of cerium nitrate, and 0.1mol of nickel nitrate and dissolve them in deionized water, then drop them into the aqueous solution of citric acid, and mix well to form a sol. Afterwards, the sol was heated to 80° C. to evaporate water, so that it gradually turned into a gel. Afterwards, the gel was dried at 100°C. The solid obtained by drying is roasted at a temperature of 600°C to obtain La 0.7 Ce 0.3 NiO 3 .

[0034] Get 0.37g magnesium nitrate and dissolve in the middle of the deionized water, the magnesium nitrate solution and the La obtained by 20g 0.7 Ce 0.3 NiO 3Mix to obtain a suspension, and carry out rotary evaporation on a rotary evaporator, so that the water is slowly evaporated to dryness, so that the magnesium ions can be evenly dispersed into the La 0.7 Ce 0.3 NiO 3 surface. The solid obtained after evaporating to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com