Rapid edge searching method for wire cutting machine

A wire cutting machine and edge-seeking technology, which is applied in the direction of electric processing equipment, metal processing equipment, accessory devices, etc., can solve the problems of not being able to quickly and automatically detect the edge-seeking, not revealing the rapid edge-finding of the wire electrode, etc., to achieve shortening Effects of edge-finding time, high-precision edge-finding positioning, and fast edge-finding positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

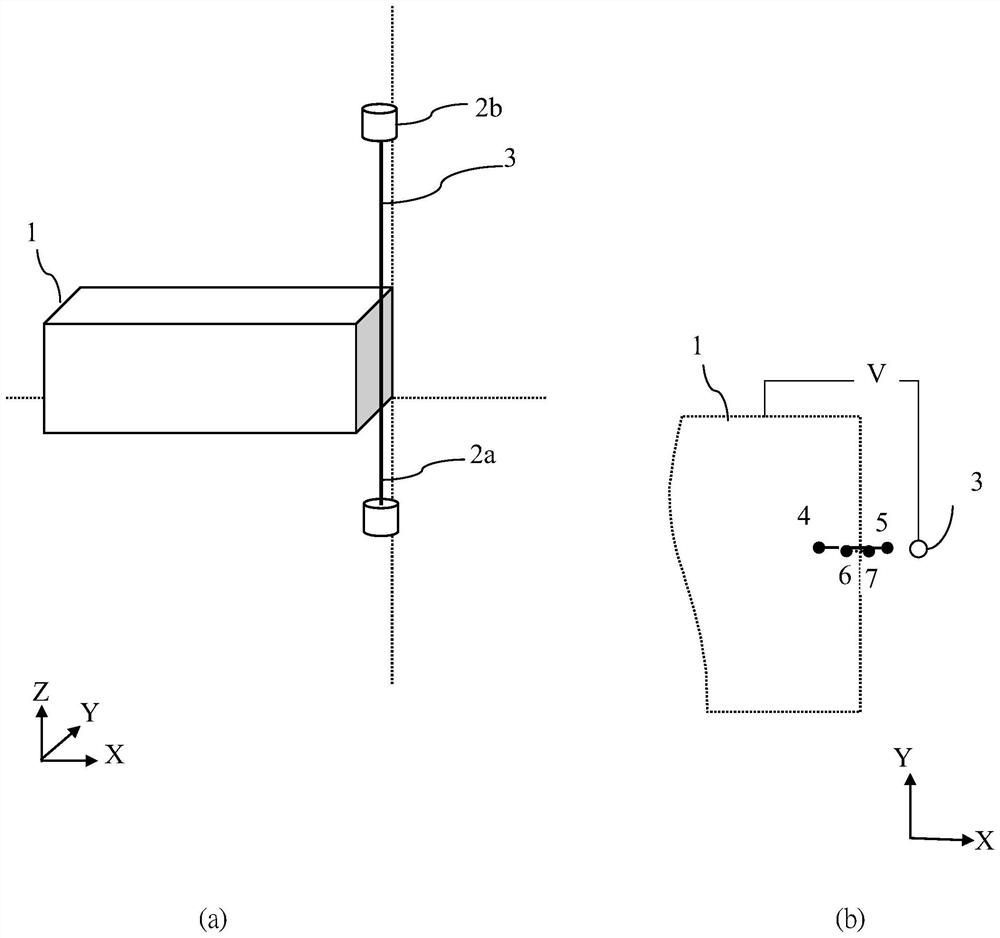

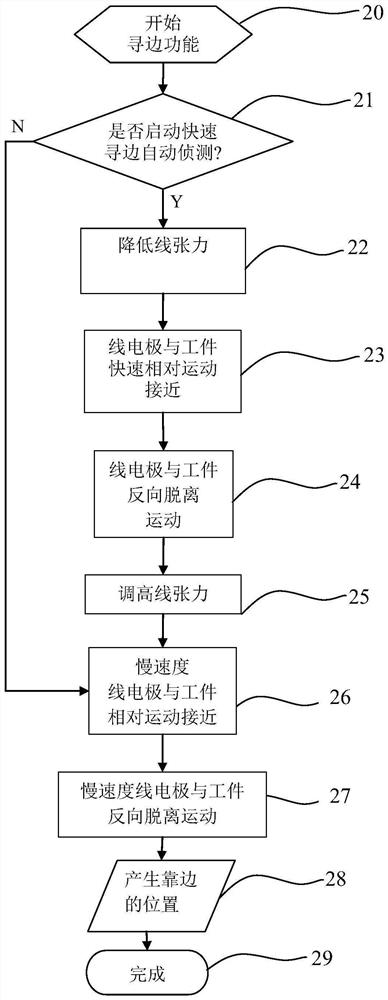

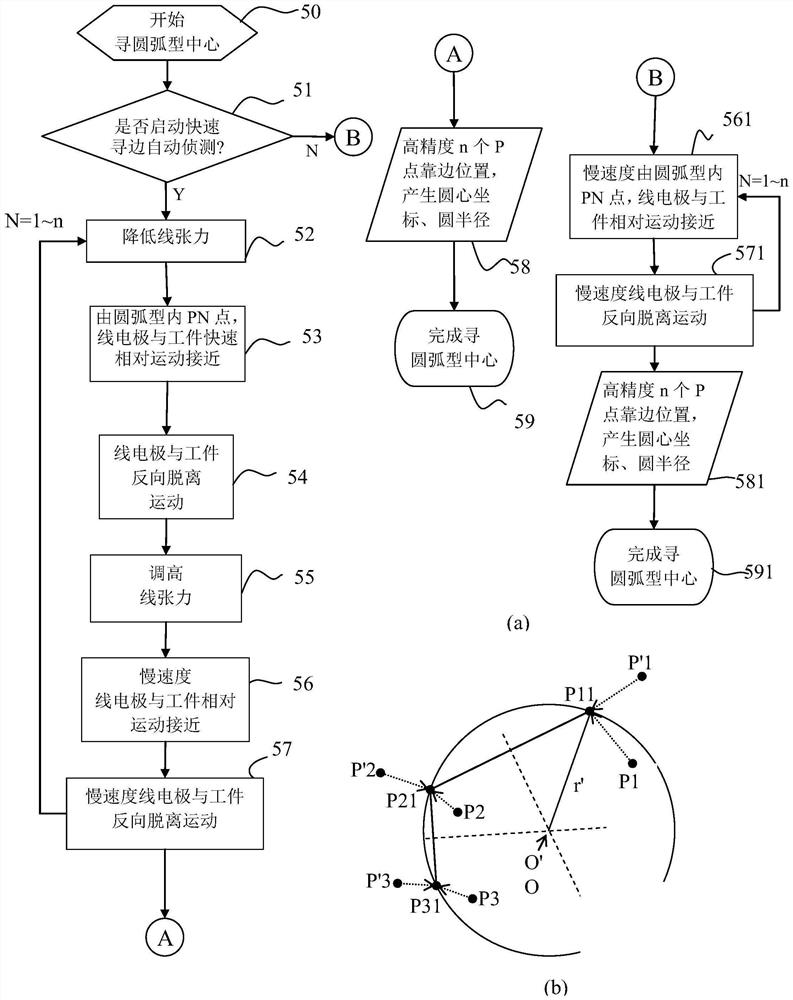

[0077] Such as figure 1 Three-dimensional schematic diagram (a) and plan schematic diagram (b) of fast edge-seeking movement. The workpiece 1 is placed on the XY horizontal worktable. The side of the workpiece 1 should be perpendicular to the worktable. Between the machine heads 2b, it should also be perpendicular to the worktable. The lower machine head 2a and the upper machine head 2b move synchronously towards the side of the workpiece 1 until the wire electrode 3 touches the side of the workpiece 1, and find that the wire electrode 3 and the workpiece 1 are just right. is the coordinates of the touched position, which is the operation process of edge finding. When performing the edge-seeking function, a detection voltage V is applied between the wire electrode 3 and the workpiece 1, and the wire electrode 3 and the workpiece 1 are made to move quickly relative to each other with a lower wire tension until the detection voltage V decreases. Stop the relative movement, beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com