Hydrogen power battery system

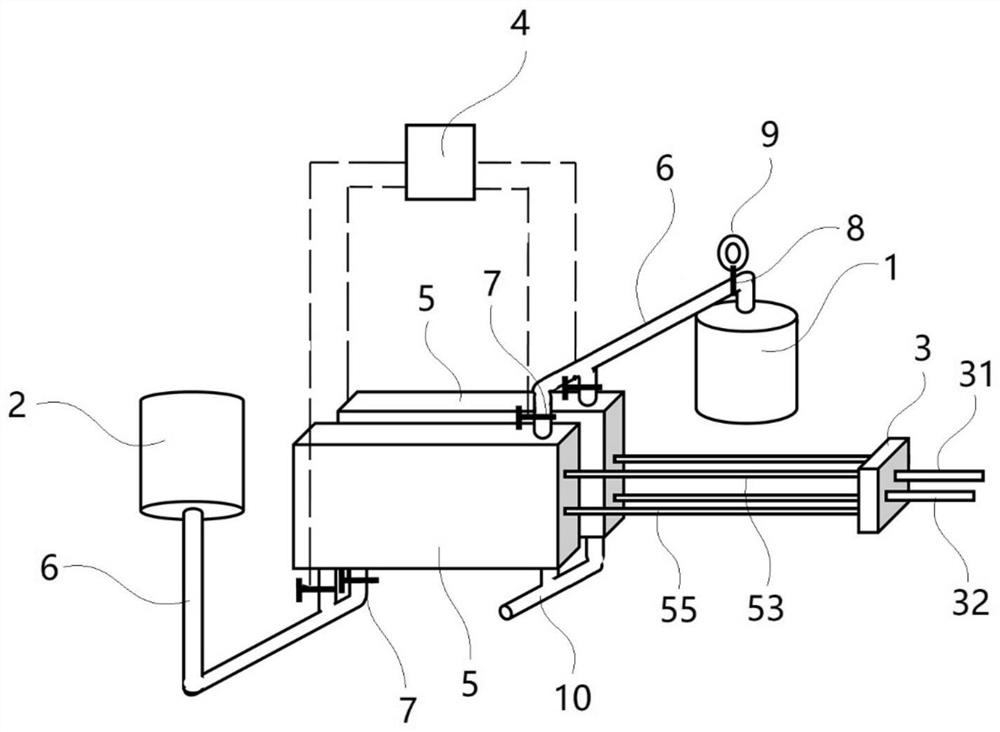

A power battery, battery body technology, applied in fuel cells, battery electrodes, fuel cell additives, etc., can solve the problems of high application cost and long charging time, and achieve the effect of reducing application cost and omitting charging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

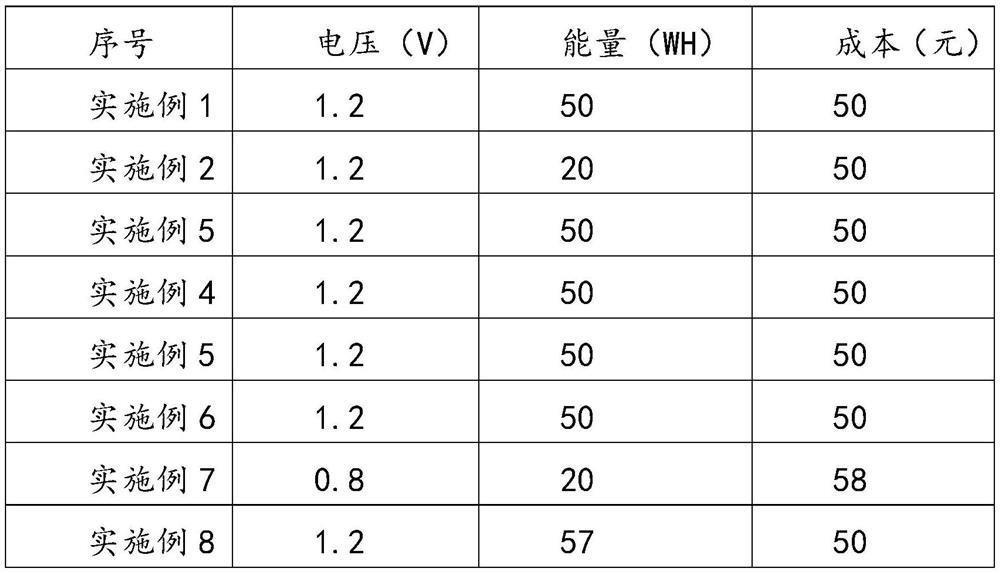

Embodiment 1

[0068] Production of battery A and battery B:

[0069] When hydrogen is charged in the negative electrode 53 of the battery, 2M+H 2 = 2MH;

[0070] When adding an oxidant to the positive electrode 55 of the battery, 2Ni(OH) 2 +H 2 o 2 =2NiOOH+2H 2 O;

[0071] The response to external discharge is:

[0072] Battery negative 53, MH+OH - =H 2 O+M+e;

[0073] Battery positive electrode 55, NiOOH+H 2 O=Ni(OH) 2 +OH — e.

[0074] During the charging and discharging process of the battery, the hydroxide ions in the alkaline electrolyte always maintain the original amount. The essence is that the added hydrogen reacts with the added oxidant to produce water.

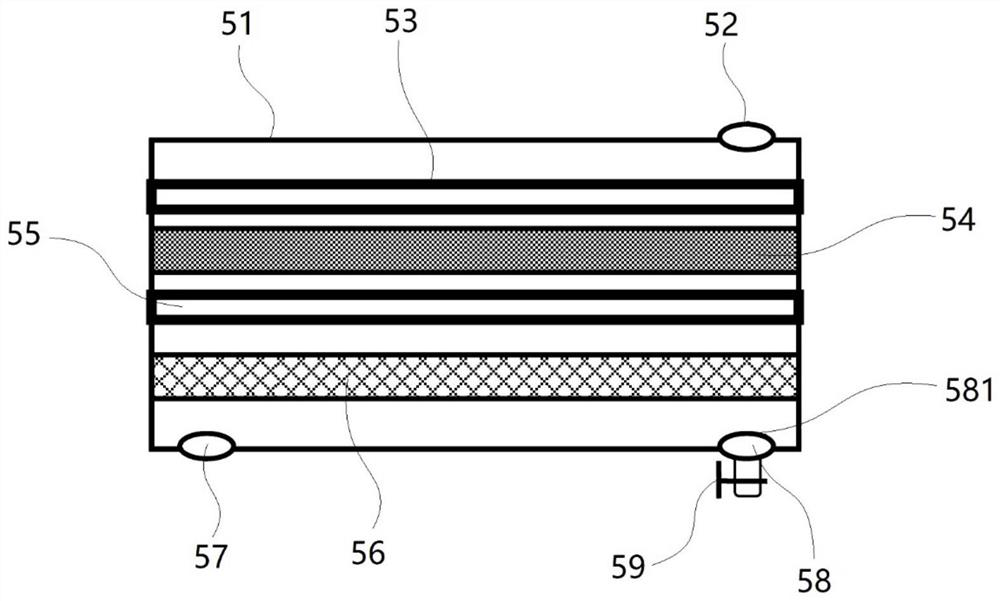

[0075] When the battery is made, the negative electrode 53 of the battery adopts AB 5 Type hydrogen storage alloy as the active material, fill 12 grams of hydrogen storage alloy powder (D50 = 49 microns) into the copper grid, and compact it with a pressure of 20Mpa to make a negative electrode sheet with a size of ...

Embodiment 2

[0083] Production of battery A and battery B:

[0084] The negative electrode 53 of the battery uses carbon nanometers as the active material, fills 12 grams of carbon nanometers into the copper mesh, and compacts it with a pressure of 20 MPa to make a negative electrode sheet with a size of 50mm*200mm*0.55mm.

[0085] Battery positive electrode 55 uses 10 grams of spherical nickel hydroxide as the active material, adds 5% cobaltous oxide as the conductive agent, fills it into foamed nickel, and compacts it with a pressure of 20Mpa to make a positive electrode sheet with a size of 50mm* 200mm*0.6mm.

[0086] The separator 54 between the battery positive electrode 55 and the battery negative electrode 53 is made of PP material, and the cutting size of the separator 54 is 52mm*205mm. The soaking membrane 56 is made of PP material, and the cutting size is 52mm*205mm.

[0087] Battery Assembly:

[0088] The above materials are stacked into the battery casing 51 in the order of ...

Embodiment 5

[0092] Production of battery A and battery B:

[0093] The battery negative electrode 53 uses La-Y-Ni type hydrogen storage alloy as the active material, fills 12 grams of hydrogen storage alloy powder (D50=49 microns) into the copper mesh, and compacts it with a pressure of 20Mpa to make a negative electrode sheet , the size is 50mm*200mm*0.55mm.

[0094] Battery positive electrode 55 uses 10 grams of spherical nickel hydroxide as the active material, adds 5% cobaltous oxide as the conductive agent, fills it into foamed nickel, and compacts it with a pressure of 20Mpa to make a positive electrode sheet with a size of 50mm* 200mm*0.6mm.

[0095] The separator 54 between the battery positive electrode 55 and the battery negative electrode 53 is made of PP material, and the cutting size is 52mm*205mm. The soaking membrane 56 is made of PP material, and the cutting size is 52mm*205mm.

[0096] Battery Assembly:

[0097] The above materials are stacked into the battery casing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com