Method for evaluating influence of volatilization of slag containing volatile components on viscosity

An evaluation method and slag technology, applied in the field of metallurgical engineering, can solve problems such as inaccurate viscosity measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] A method for evaluating the influence of volatilization of slag containing volatile components on viscosity in the present invention, comprising:

[0050] Taking the relevant measurement data of fluorine-containing slag for steelmaking as an example for illustration, where fluoride is a volatile component, the implementation of other volatile slags is similar.

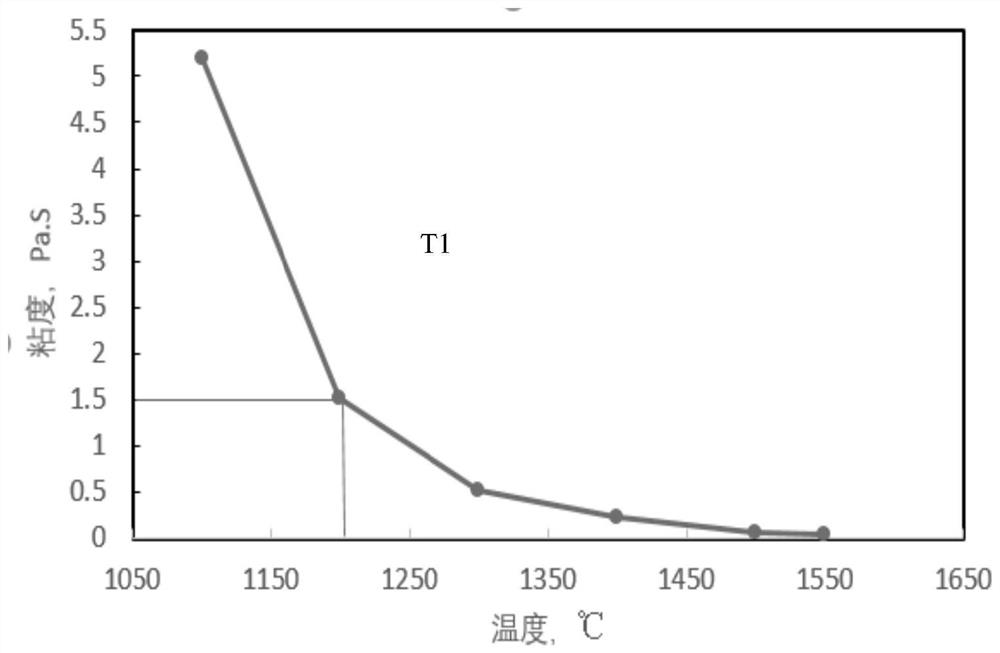

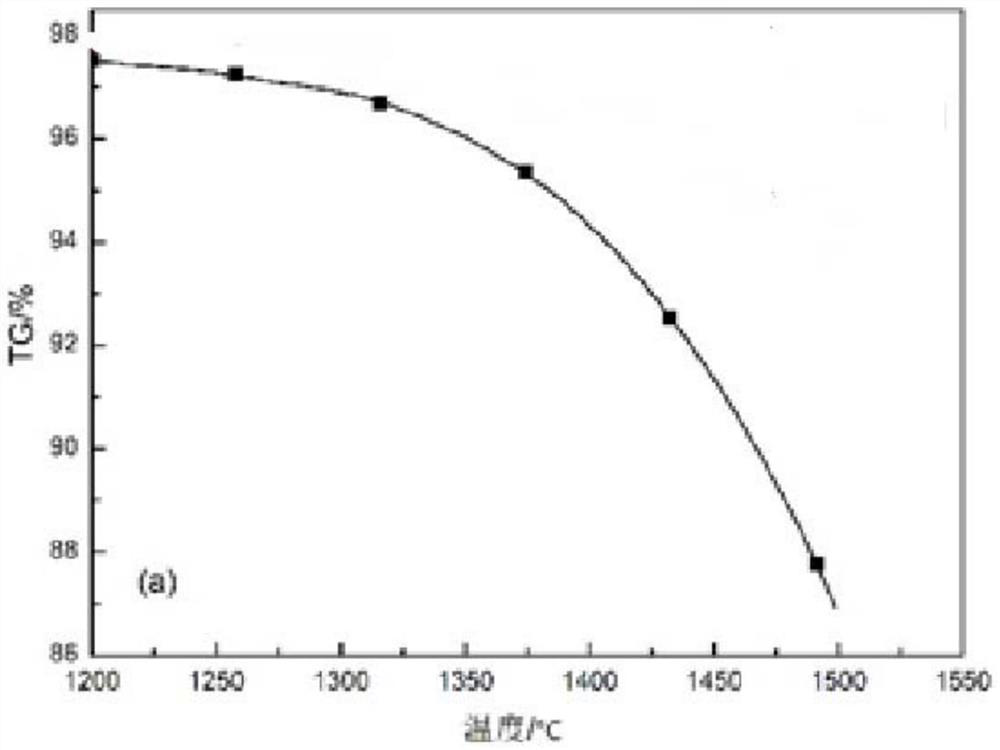

[0051] Determination method and data extraction: Viscosity measurement still adopts the traditional rotating cylinder measurement method, and the η-t relationship diagram can be obtained, which can be called the apparent viscosity and temperature relationship of volatile slag, such as figure 1 shown. At the same time as the viscosity measurement, the thermogravimetric or burning sample test under the same conditions as the slag sample is carried out, that is, the thermogravimetric and volatilization mechanism research or burning sample under the same conditions as the temperature rise, heat preservation, atmosph...

Embodiment 2

[0060] Data extraction and volatilization impact evaluation of slag viscosity measurement process for electroslag remelting

[0061] basic situation:

[0062] The original composition of slag for electroslag remelting is shown in Table 1.

[0063] Table 1 Electroslag composition

[0064] composition al 2 o 3

MgO SiO2 CaF 2

CaO content / % 29.33 2.57 9.15 30.12 28.83

[0065] According to the conventional viscosity measurement method, the relationship between the slag viscosity and temperature can be obtained as figure 1 shown. It is also determined that the slag loses weight at a high temperature during the viscosity measurement process, and the weight loss at a high temperature above 800°C can reach 8.2%.

[0066] Application method:

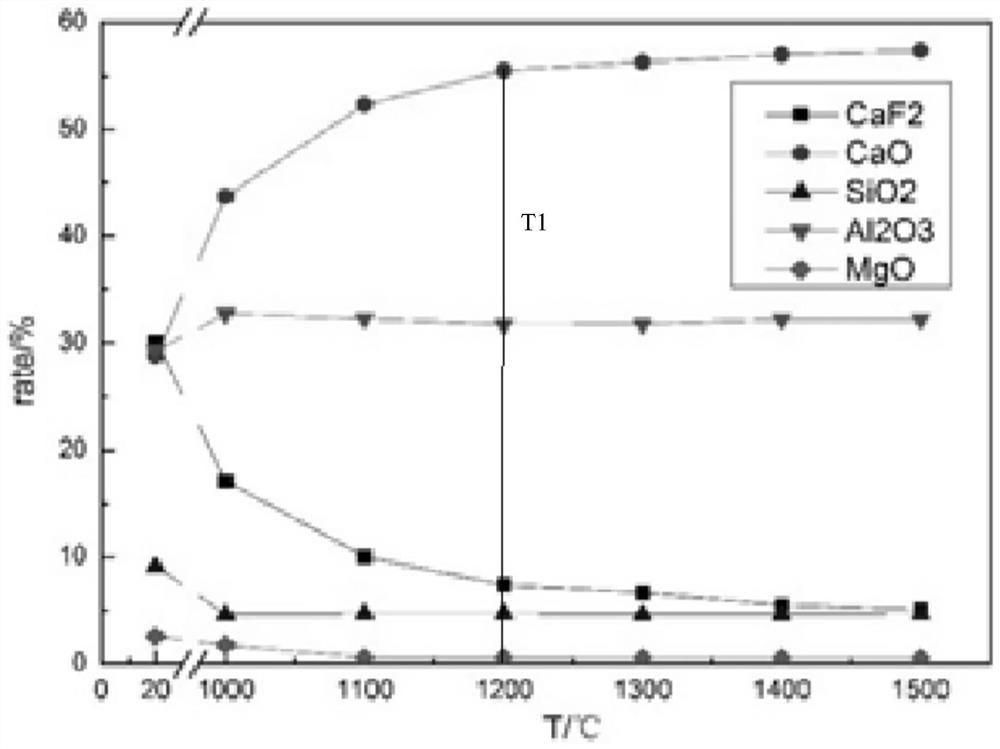

[0067] Using the atmosphere, heating rate and holding time of conventional viscosity measurement, the slag roasting test was carried out, and the slag composition changes in the process were obtain...

Embodiment 3

[0074] Data extraction and volatilization impact evaluation of a molten iron pretreatment slag viscosity measurement process

[0075] basic situation:

[0076] The composition of steelmaking slag is shown in Table 3.

[0077] Table 3 Composition of fluorine-containing steelmaking slag (mass fraction)

[0078] composition CaF 2

Al 2 o 3

MgO SiO 2

CaO Na 2 CO 3

content 17.6 3.8 3.0 27.2 27.2 21.2

[0079] According to the conventional viscosity measurement method, the relationship between viscosity and temperature can be obtained as Figure 6 The curve shown in . It is also determined that the high temperature weight loss (weight loss above 800° C.) of the slag during the viscosity measurement process can reach 11.6%.

[0080] Application method:

[0081] Using the atmosphere, heating rate and holding time of conventional viscosity measurement, the slag roasting test was carried out, and the slag composition changes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com