Industrial robot stacking workstation

A technology of industrial robots and workstations, applied in stacking, unstacking, transportation and packaging of objects, etc., can solve the problems of bulky volume, and achieve the effects of small volume, easy installation, transportation and debugging, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

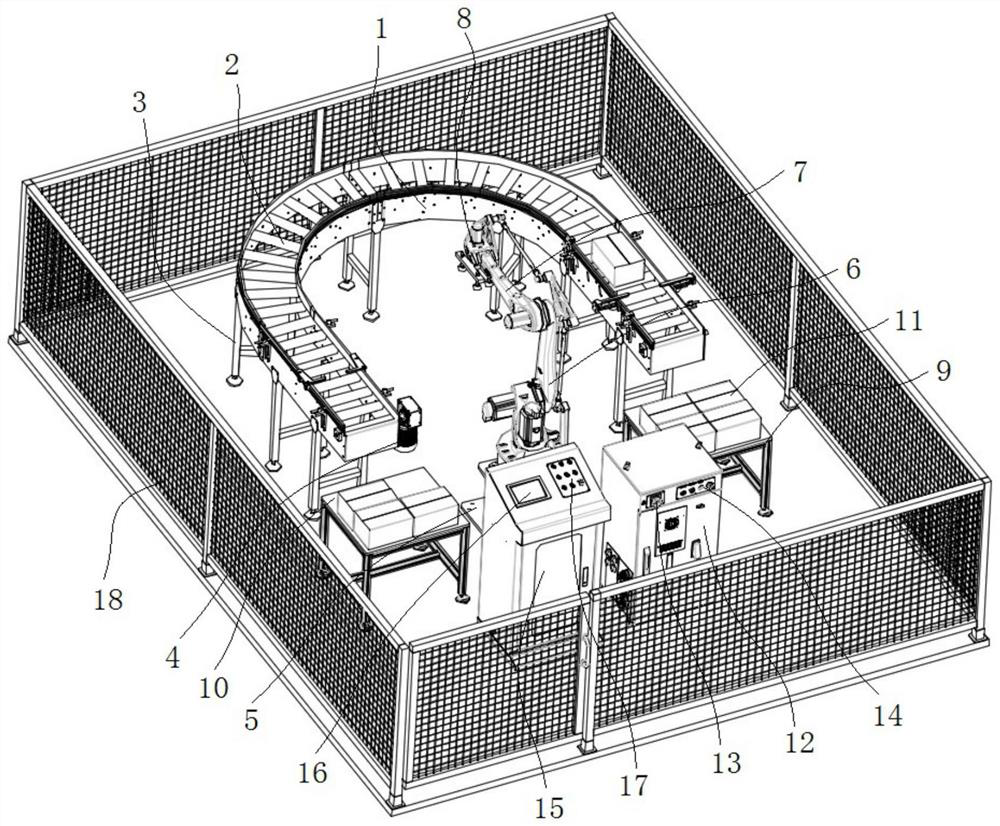

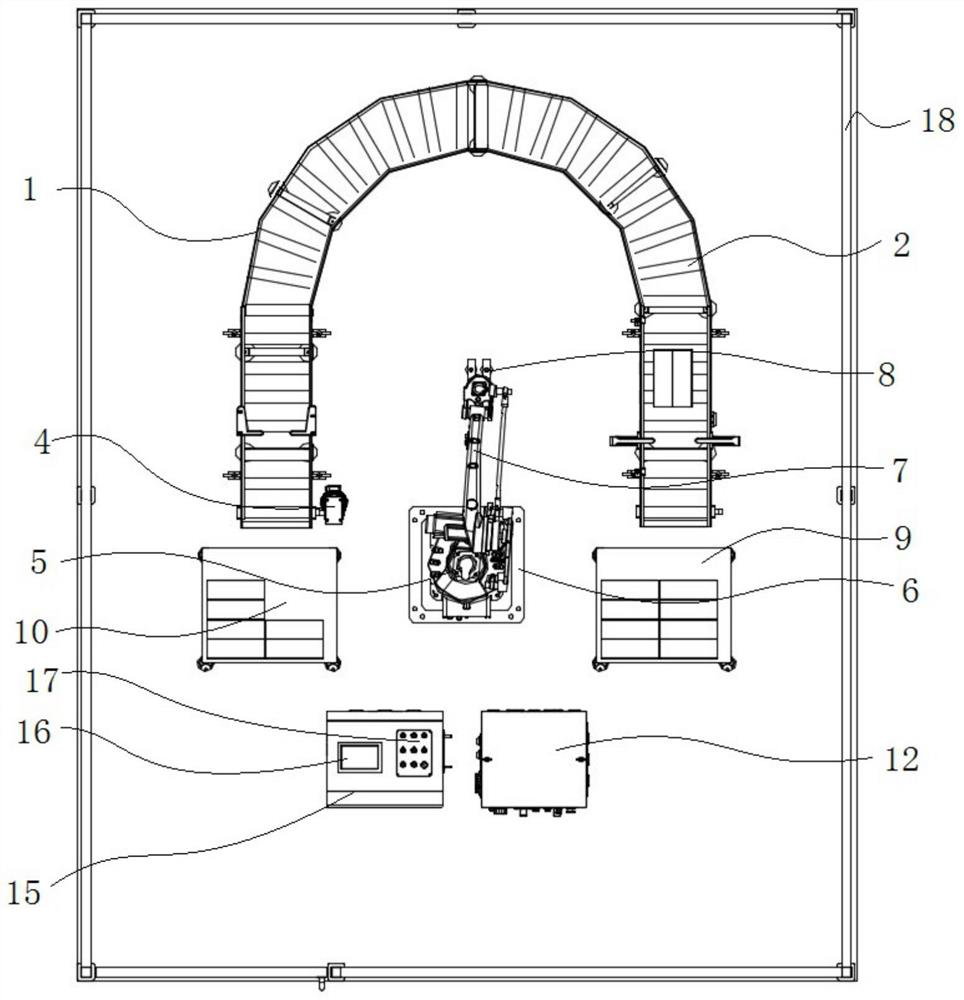

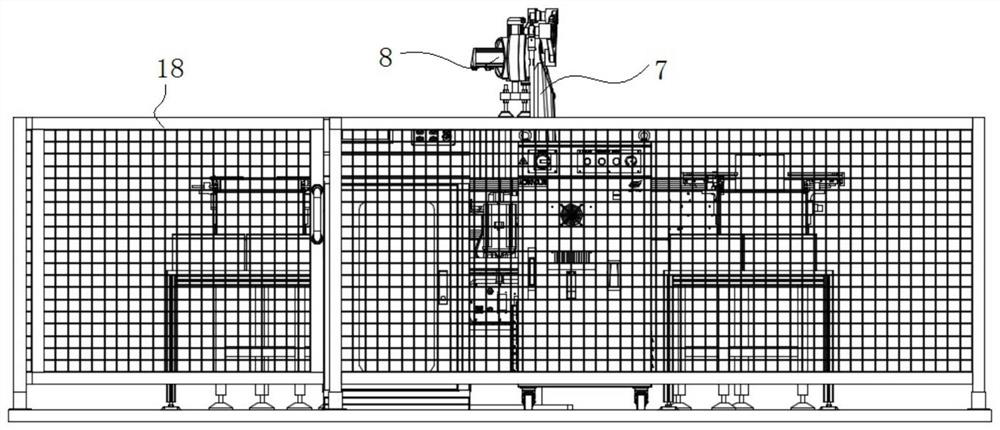

[0028] see Figure 1-5 As shown, the present invention is an industrial robot palletizing workstation, including a U-shaped installation frame 1, a U-shaped conveying line 2 and a frequency conversion motor 4, the U-shaped conveying line 2 is installed inside the U-shaped installing frame 1, and the U-shaped conveying line 2 The type can be a roller conveyor line, or a PVC flat belt conveyor line or a plate chain conveyor line. The trajectory of its conveying materials is like a "U-shaped word". Cooperate with the U-shaped conveying line 2, which can make the U-shaped conveying line 2 rotate forward and reverse, so as to realize circular palletizing. Several installation brackets 3 are installed on the lower surface of the U-shaped installation frame 1, and one end of the U-shaped conveying line 2 is placed A first palletizing platform 9 is installed, a second palletizing platform 10 is placed at the other end of the U-shaped conveying line 2, and a number of palletizing objec...

Embodiment 2

[0034] see Figure 1-5 As shown, the present invention is an industrial robot palletizing workstation, and its use method is as follows: first, the corresponding palletizing fixture can be selected according to the training object. If the training object is a carton, a vacuum suction gripper or a Splint-type manipulator claws, if it is bagged, use grabbing-type manipulator claws to fix the palletizing fixture on the end joint 7 of the industrial robot 6; place the palletizing objects 11 on the first palletizing platform 9 and the second On the palletizing platform 10, there are corresponding scales on the first palletizing platform 9 and the second palletizing platform 10, and they are placed according to the original position and size; after checking that the circuit and the gas circuit are normal, power on, start the industrial robot 6, and manually coordinate point calibration of the industrial robot 6; after completion, press the start button of the electrical control cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com