Adhesive primer composition and preparation method thereof

A primer and adhesion technology, which is applied in the direction of surface pretreatment bonding method, coating, polyurea/polyurethane coating, etc., can solve the problem of easy degumming, poor adhesion, and inability to achieve glass light blocking effect and other issues, to achieve a good light blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

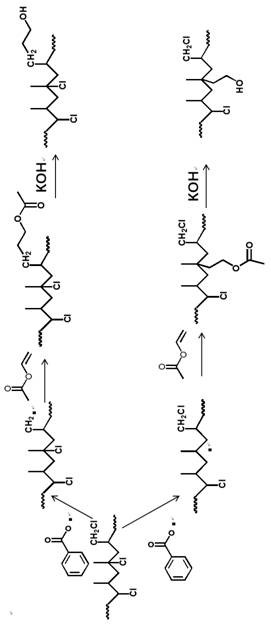

Method used

Image

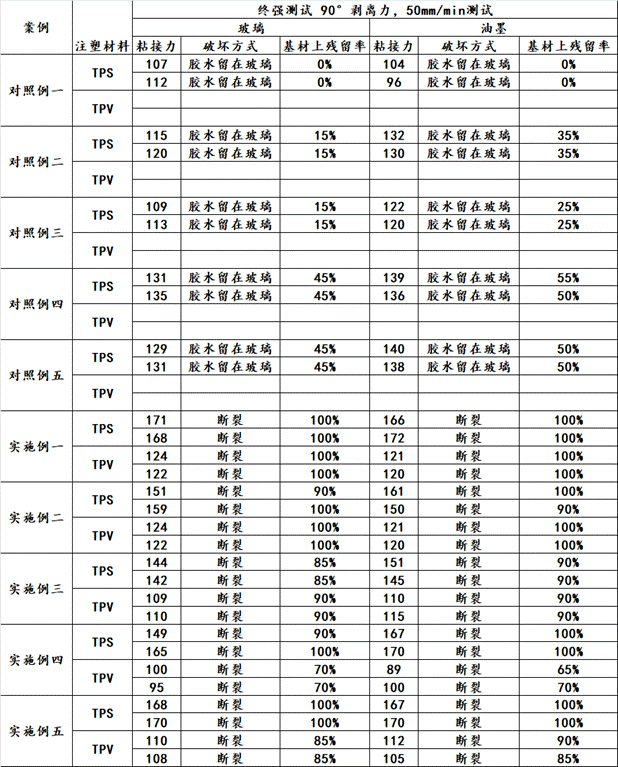

Examples

preparation example Construction

[0032] The embodiments of the present application also provide a method for preparing an adhesive primer, in which the reagents used in the method are all industrial-grade reagents, and the method includes the following steps:

[0033] Step 1: Prepare component A, mix the polyhydroxy compound containing the polyolefin structure and the modified graphite oxide in a preset ratio, and the weight of the modified graphite oxide is 0.5%-5% of the weight of the polyhydroxy compound.

[0034]Step 2: Prepare component B, first react soybean oil polyol with isocyanate, and then react with hydrogenated bisphenol A in a preset weight ratio to obtain a soybean oil polyol added with hydrogenated bisphenol A, and then react isocyanate with hydrogenated bisphenol A. The soybean oil polyol added by A continues to react, and the viscosity of the reactant is monitored. When the viscosity does not continue to increase, a modified product of soybean oil polyol is obtained.

[0035] When component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com